Soil improver and preparation method thereof

A soil improver and modification technology, which is applied in the direction of soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problem of lack of improvement and regulation of soil air permeability, water retention and reunion ability, poor comprehensive functionality, Short fertilizer action time and other problems, to reduce soil nutrient loss, enhance water and fertilizer retention capacity, and enhance the effect of fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

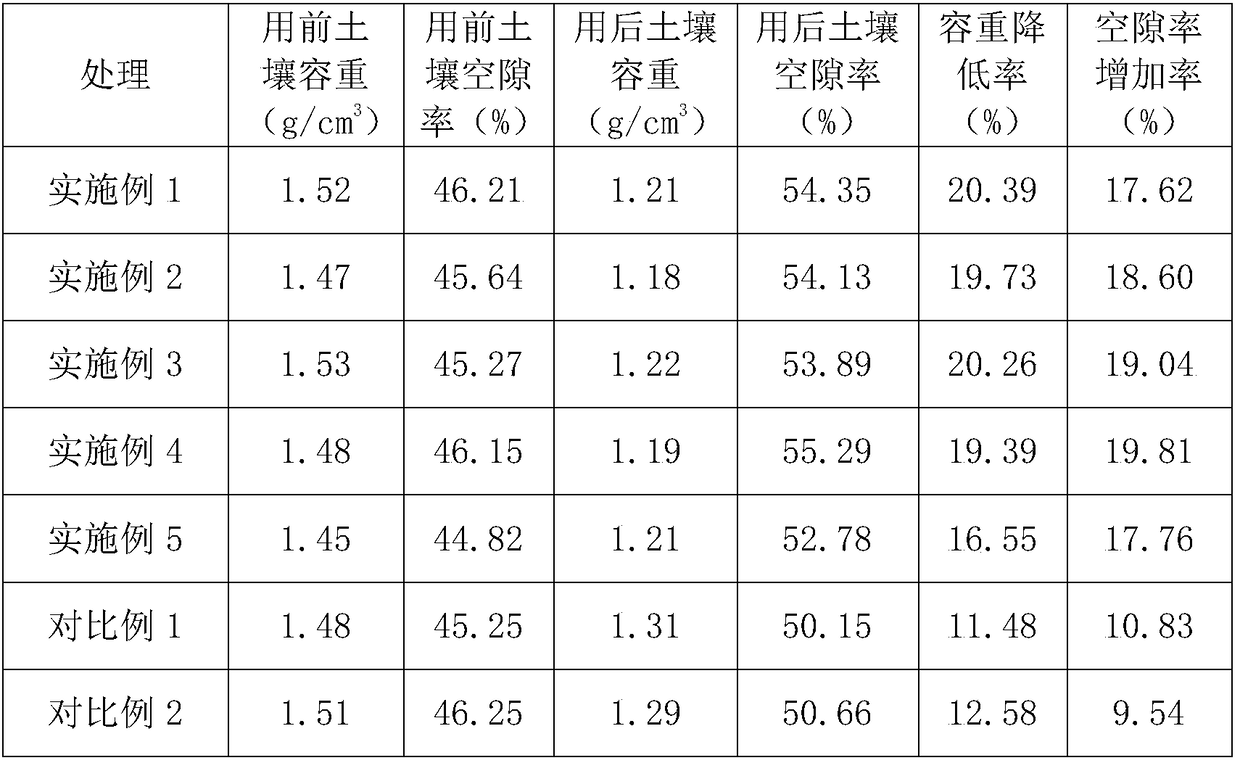

Examples

Embodiment 1

[0034] A soil conditioner, comprising the following raw materials in parts by weight:

[0035] 17 parts of bentonite, 9 parts of modified montmorillonite powder, 5 parts of silicon dioxide, 4 parts of volcanic ash, 5 parts of carbon bran, 21 parts of animal manure, 6 parts of fermentation residue, 2 parts of nepeta stem, 2 parts of eagle claw wind, phosphorus 4 parts of mineral powder, 3 parts of silicon and potassium fertilizer, 2 parts of desulfurized gypsum, 2 parts of potassium fulvic acid, 1 part of microbial powder, 1 part of nutrient and 1.2 parts of organic acid.

[0036] The preparation method of modified montmorillonite powder is as follows:

[0037] (1) After roasting the montmorillonite at 400 degrees Celsius for 3 hours, grind it into powder, soak it in 10% hydrogen peroxide for 3 hours, wash it with deionized water, and dry it;

[0038] (2) in the product of step (1), add and be equivalent to its weight 1% sodium lauryl sulfate, 2% α-ethyl cyanoacrylate, 1% chlo...

Embodiment 2

[0050] A soil conditioner, comprising the following raw materials in parts by weight:

[0051] 22 parts of bentonite, 15 parts of modified montmorillonite powder, 10 parts of silicon dioxide, 8 parts of volcanic ash, 10 parts of carbon bran, 26 parts of animal manure, 12 parts of fermentation residue, 5 parts of Nepeta stalk, 5 parts of eagle claw wind, phosphorus 8 parts of mineral powder, 7 parts of silicon and potassium fertilizer, 5 parts of desulfurized gypsum, 5 parts of potassium fulvic acid, 3 parts of microbial powder, 3 parts of nutrient and 2.5 parts of organic acid.

[0052] The preparation method of modified montmorillonite powder is as follows:

[0053] (1) After roasting the montmorillonite at 500 degrees Celsius for 4 hours, grind it into powder, soak it in 15% hydrogen peroxide for 5 hours, wash it with deionized water, and dry it;

[0054] (2) in the product of step (1), add the sodium lauryl sulfate that is equivalent to its weight 2%, 3% α-ethyl cyanoacryl...

Embodiment 3

[0066] A soil conditioner, comprising the following raw materials in parts by weight:

[0067] 18 parts of bentonite, 11 parts of modified montmorillonite powder, 6 parts of silicon dioxide, 5 parts of volcanic ash, 6 parts of carbon bran, 22 parts of animal manure, 8 parts of fermentation residue, 3 parts of nepeta stem, 3 parts of eagle claw wind, phosphorus 5 parts of mineral powder, 4 parts of silicon and potassium fertilizer, 3 parts of desulfurized gypsum, 3 parts of potassium fulvic acid, 1.5 parts of microbial powder, 1.5 parts of nutrient and 1.6 parts of organic acid.

[0068] The preparation method of modified montmorillonite powder is as follows:

[0069] (1) After roasting the montmorillonite at 450 degrees Celsius for 3.5 hours, grind it into powder, soak it in 12% hydrogen peroxide for 4 hours, wash it with deionized water, and dry it;

[0070] (2) in the product of step (1), add the sodium lauryl sulfate that is equivalent to its weight 1.5%, 2.5% α-ethyl cyan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com