A metal-organic framework crystal functional material and its preparation method and application

A metal-organic framework and functional material technology, which is applied in the field of metal-organic framework crystal functional materials and its preparation, can solve the problems of low room temperature discoloration accuracy, limited discoloration temperature, and long recoloring time, and achieve a wide range of light absorption and discoloration The effect of low temperature and short recoloring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 sample preparation:

[0043] Mix the indium source, cobalt source, 1,3,5-trimesic acid, 1,3-dimethyl-tetrahydro-2-pyrimidinone and water in a certain proportion to obtain the initial gel mixture, and the initial gel The mixture was sealed in a 30mL polytetrafluoroethylene-lined hydrothermal reaction kettle, placed in a box-type resistance furnace, crystallized at the crystallization temperature for a period of time, filtered, washed, and dried to obtain purple-black flakes [ In 2 co 5 (BTC) 2 (HBTC) 3 (μ-O) 4 (H 3 O) 4 ]·(H 2 O) 9 crystal sample. Table 1 shows the relationship between the types and ratios of raw materials in the initial gel mixture, crystallization temperature, crystallization time, and sample numbers.

[0044] Table 1 Relationship between sample synthesis conditions and sample numbers

[0045]

Embodiment 2

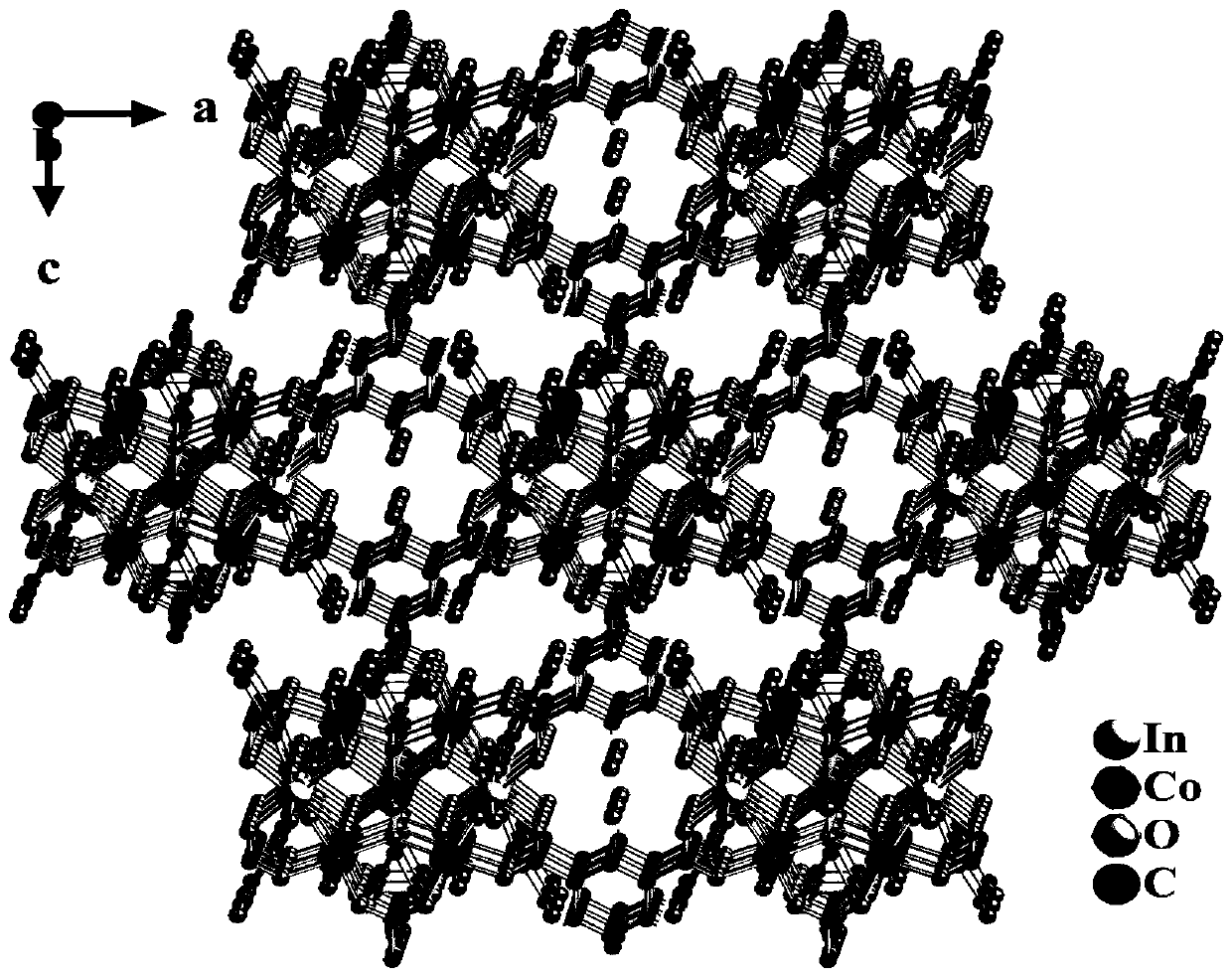

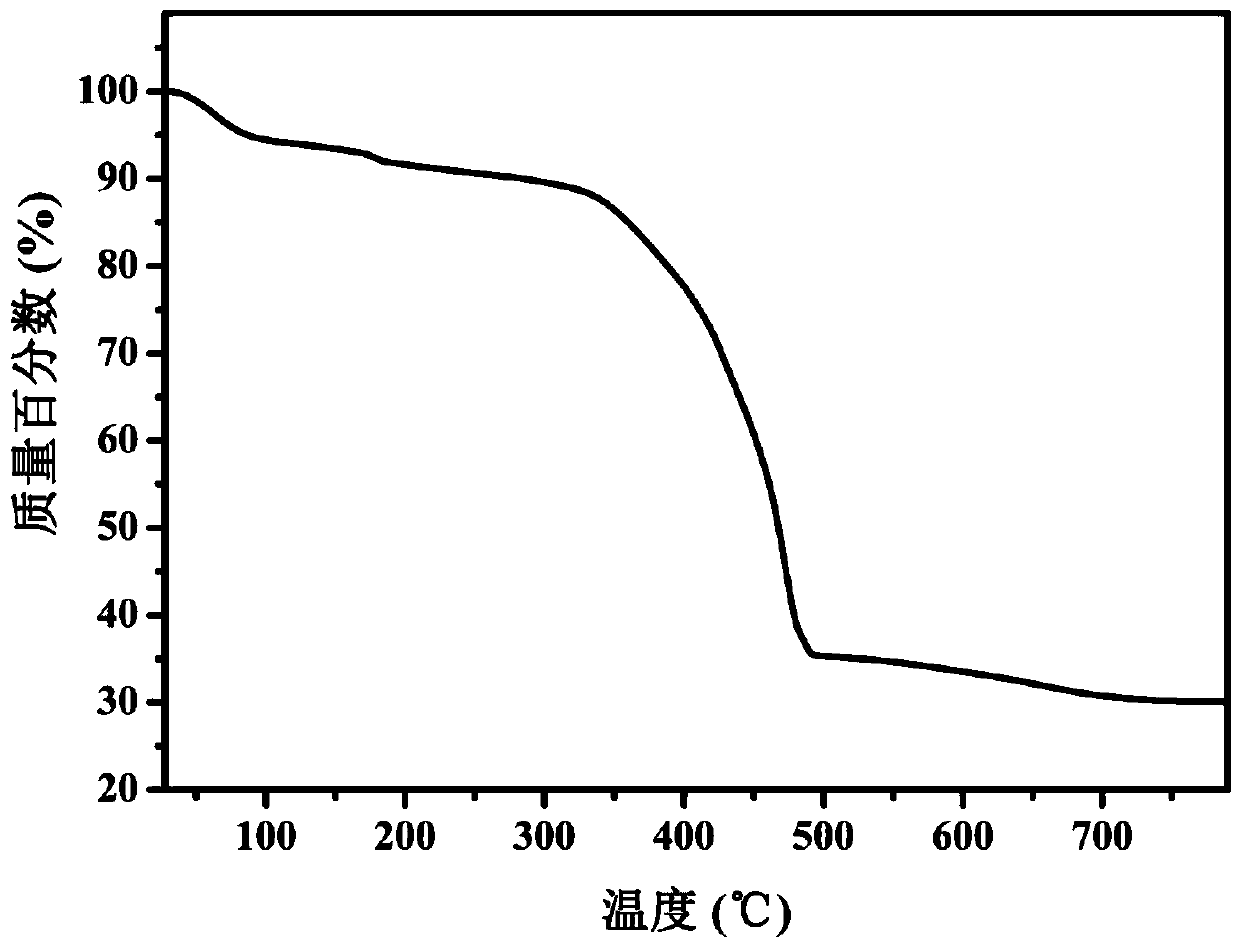

[0046] The crystal structure analysis of embodiment 2 sample:

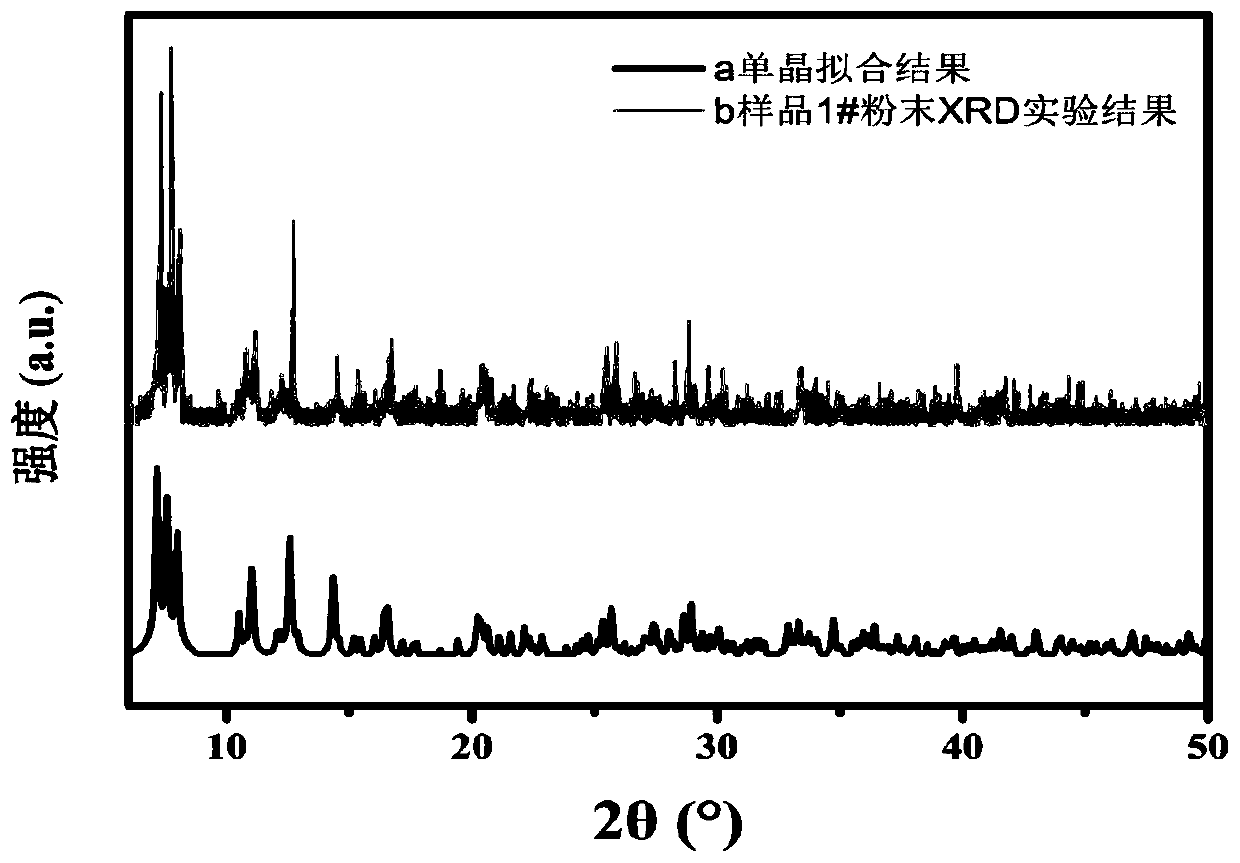

[0047] The structures of samples 1# to 10# were analyzed by single crystal X-ray diffraction and powder X-ray diffraction.

[0048] The single crystal X-ray diffraction was performed on a Rigaku Mercury CCD type X-ray single crystal diffractometer from Bruker, Germany. The crystal size is 0.12×0.10×0.12mm 3 ; The data collection temperature is 293K, and the diffraction light source is Mo-Kα ray monochromated by graphite The scanning method is ω-2θ; the data is processed by the Multi-Scan method for absorption correction. Structural analysis was completed using the SHELXTL-97 program package; the position of the heavy atom was determined by the direct method, and the coordinates of the remaining atoms were obtained by the difference Fourier synthesis method; 2 The full-matrix least-squares method was used to refine all atomic coordinates and anisotropic thermal parameters.

[0049] Powder X-ray diffraction was...

Embodiment 3

[0058] Embodiment 3 reversible discoloration experiment and result:

[0059] Take an appropriate amount of sample 1# material, place it evenly in a watch glass, heat it in an oven at different temperatures, observe the color change of the sample, and record the color change time; take out the watch glass, observe the recolor change in the air, and record the recolor time. The discoloration performance of the low-temperature reversible thermochromic material was tested, and the results are shown in Table 1.

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com