Method for preparing up-conversion aptamer test strip for rapid detection of ochratoxin A

A technology of ochratoxin and aptamer, which is applied in the field of preparation of up-conversion aptamer test strips, can solve problems such as complex process, long antibody preparation cycle, time-consuming and laborious preparation of test strips, etc., to reduce production costs, Effect of reducing background noise and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

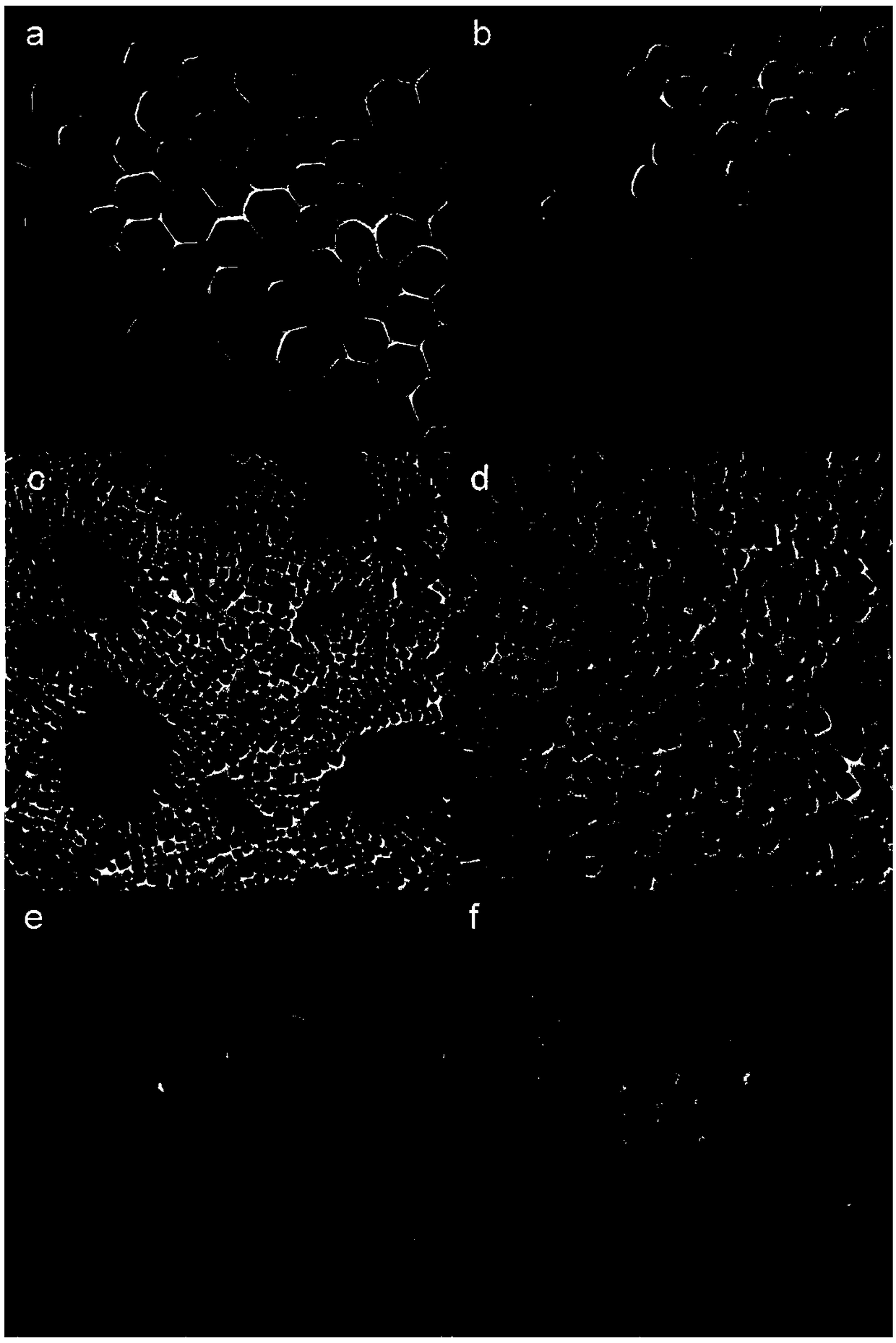

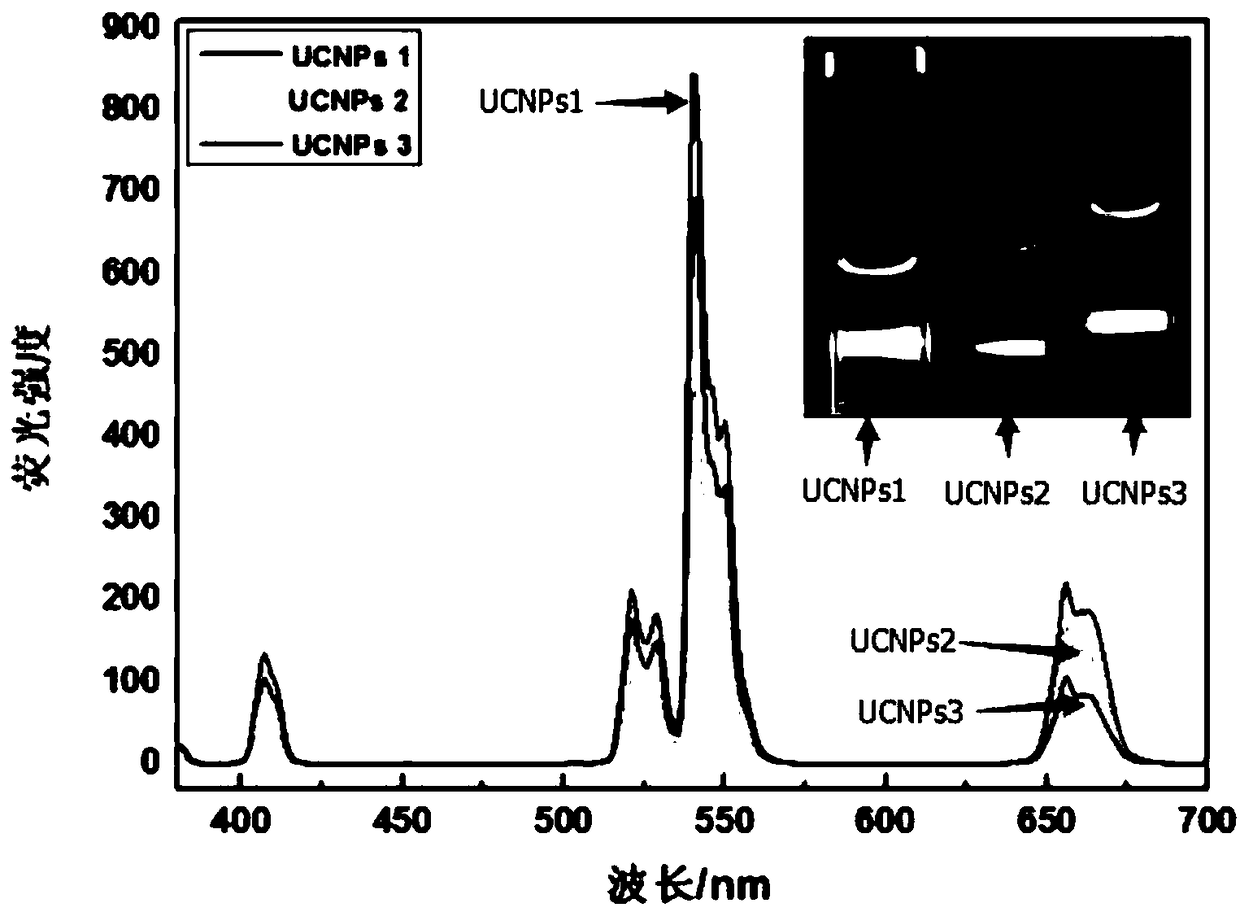

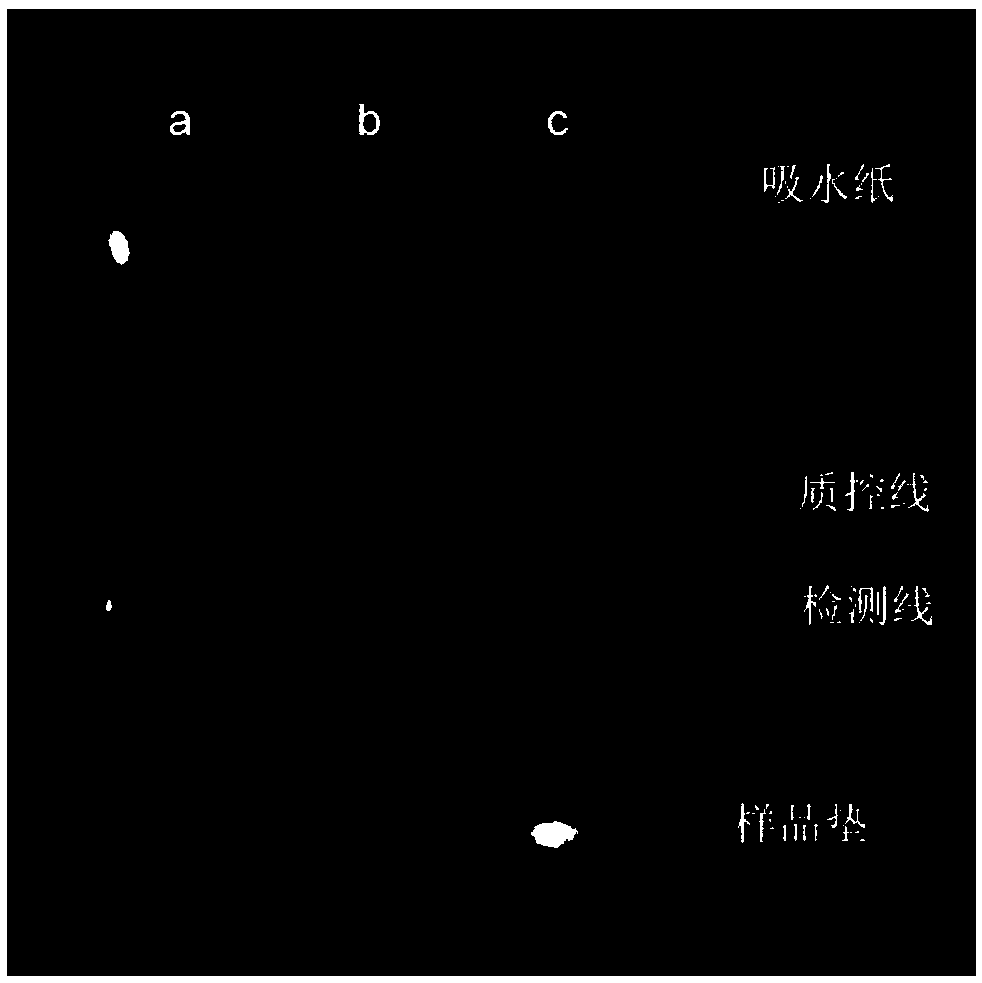

[0031] Synthesis of Upconversion Luminescent Nanomaterials UCNPs 1 : Weigh YbCl 3 ·6H 2 O, YCl 3 ·6H 2 O and ErCl 3 (78%Y 3+ , 20%Yb 3+ , 2% Er 3+ ) was added to a 100mL three-necked flask, and 6mL oleic acid and 15mL octadecene were added. Under stirring and nitrogen atmosphere, gradually raise the temperature to 160°C to make the reagents form a uniform solution, and cool naturally to room temperature. Weigh 4mmol NH 4 F and 2.5mmol NaOH were dissolved in 10mL methanol solution. The above solution was added dropwise into a three-necked flask, heated up to 60° C. and magnetically stirred for 30 minutes, and then gradually heated up to remove methanol by evaporation. Continue to flow argon, add a condensing reflux device, raise the temperature to 300°C, and continue the reaction for 1h. After the reaction was over, the device was closed and cooled to room temperature naturally. The material was centrifuged and washed three times with water and ethanol, and dried at...

Embodiment 2

[0041] Synthesis of Upconversion Luminescent Nanomaterials UCNPs 2 , the specific method is as follows: add 0.3g NaOH, 1.5mL deionized water, 5mL oleic acid and 10mL ethanol into a 100mL beaker in sequence, stir and mix quickly to form a transparent and uniform solution. Weigh 1.6mL Y(NO 3 ) 3 ·6H 2 O(0.5mol / L), 0.9mL Yb(NO 3 ) 3 ·5H 2 O (0.2mol / L), 0.1mL Yb (NO 3 ) 3 ·5H 2 O (0.2mol / L) was added dropwise to the above solution, and stirred vigorously to mix. Weigh 0.168g NaF, dissolve it in 4mL deionized water, and add it dropwise to the above mixed solution. Stir vigorously for 15 min, then transfer the mixture to a 100 mL polytetrafluoroethylene-lined reactor, and react at 200 °C for 8 h. After the reaction, the reactor was taken out to cool down to room temperature naturally, and the bottom precipitate was collected, washed three times with ethanol centrifugation, and dried at 70°C for 8 hours to obtain a white solid powder, which was stored for future use.

[00...

Embodiment 3

[0044] Synthesis of Upconversion Luminescent Nanomaterials UCNPs 3 , the specific method is as follows: take 0.18g Y 2 o 3 (28%), 0.788gYb 2 o 3 (70%) and 0.022g Er 2 o 3 (2%), respectively added into the nitric acid solution, heated to dissolve, and evaporate excess nitric acid to obtain the nitrate powder of the above rare earth element. After dissolving in 8 mL of deionized water, add 2.1273 g of ethylenediaminetetraacetic acid (EDTA) to adjust the pH of the solution to be weakly alkaline and fully dissolve. Measure 25mL of ethylene glycol solution, add 0.4g of cetyltrimethylammonium bromide (CTAB) and the above mixture, and stir rapidly. 1.5 mL HF was added dropwise. After the solution turns into a white milky colloid, add 3.5mL of concentrated nitric acid, stir evenly, then transfer to a 100mL reaction kettle with a polytetrafluoroethylene liner, and react at 195°C for 24h. After the reaction was finished, the device was closed, and the reactor was taken out, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com