Conductive polymer-coated silicon composite carbon nanotube anode material and preparation method and application thereof

A technology of conductive polymer and negative electrode material, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of poor electrode cycle performance, material structure damage, mechanical pulverization, etc., achieve good electrical conductivity, inhibit volume expansion, reduce The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

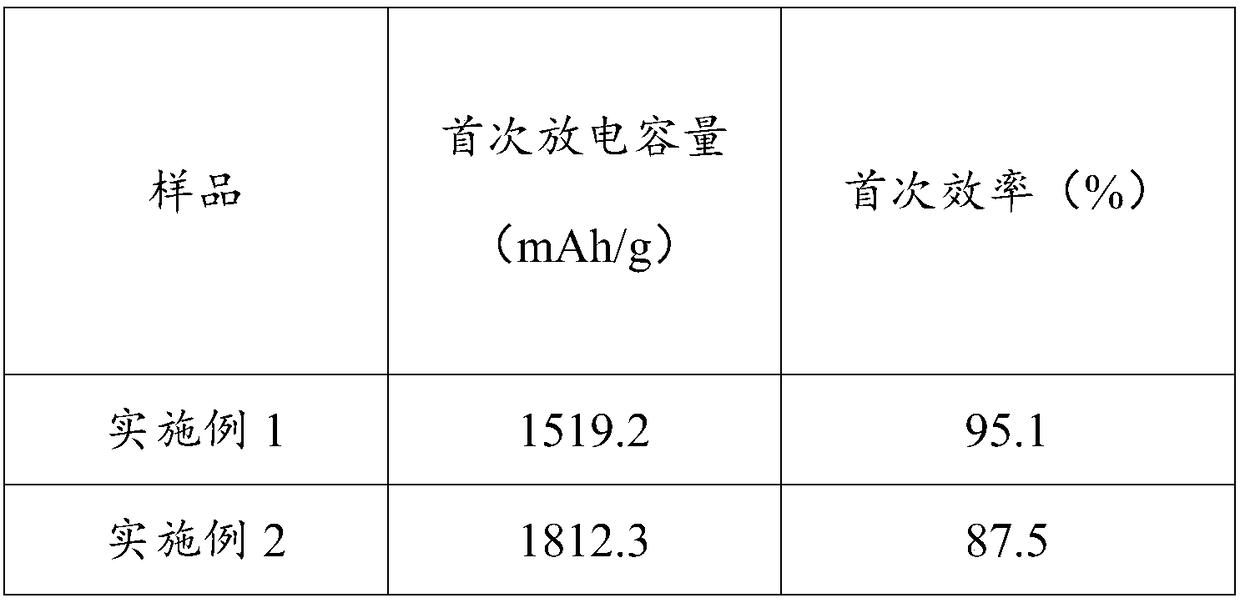

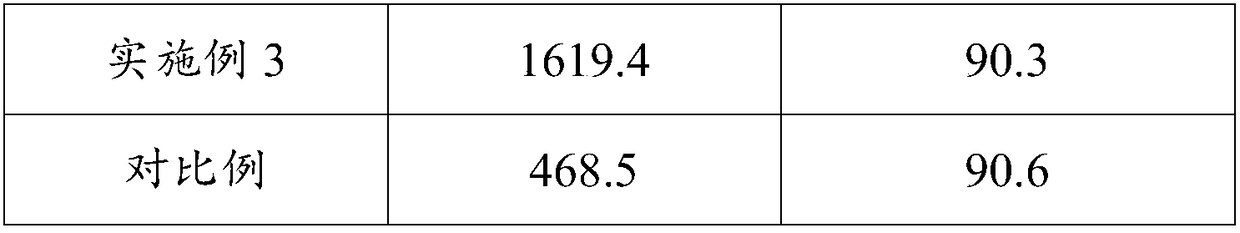

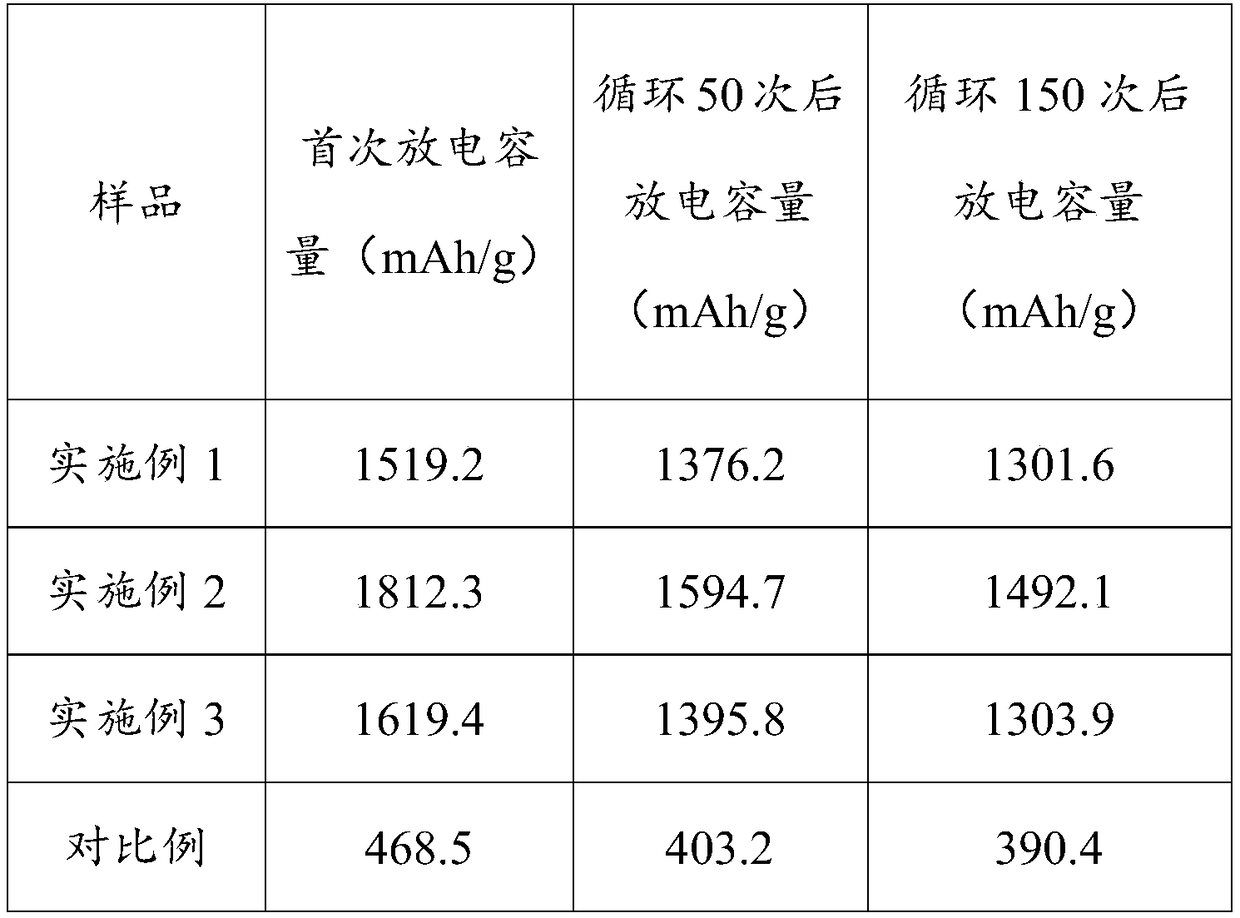

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing a conductive polymer-coated silicon composite carbon nanotube negative electrode material, which includes the following steps:

[0031] (1) Disperse elemental silicon (D50=7 micron, purity 99.95%, iron content<120ppm) in water, grind through sand mill 4h, obtain nano-silicon dispersion liquid, silicon particle diameter in the described nano-silicon dispersion liquid is D50= 300nm;

[0032] (2) get emulsifier dodecylbenzenesulfonic acid DBSA (also be the protonic acid dopant of polyaniline simultaneously) and emulsion dispersion agent dodecyl ammonium sulfate ALS respectively and dissolve in water, described emulsifier and described The molar ratio of the emulsion dispersant is 1:1, and then aniline monomer is added, the mass ratio of the aniline monomer to the emulsifier is 1:1.7, fully stirred and mixed uniformly, and the particle size of the emulsion droplet is 20-30nm aniline microemulsion;

[0033] (3) adding the nan...

Embodiment 2

[0038] This embodiment provides a method for preparing a conductive polymer-coated silicon composite carbon nanotube negative electrode material, which includes the following steps:

[0039] (1) Disperse elemental silicon (D50=7 micron, purity 99.95%, iron content<120ppm) in water, grind through sand mill 2h, obtain nano-silicon dispersion liquid, silicon particle diameter in the described nano-silicon dispersion liquid is D50= 1000nm;

[0040](2) get emulsifier dodecylbenzenesulfonic acid DBSA (also be the protonic acid dopant of polyaniline simultaneously) and emulsion dispersion agent dodecyl ammonium sulfate ALS respectively and dissolve in water, described emulsifier and described The molar ratio of the emulsion dispersant is 1:1, and then add aniline monomer, the mass ratio of the aniline monomer to the emulsifier is 1:1, fully stir and mix uniformly, and the particle size of the emulsion droplet is 110-120nm aniline microemulsion;

[0041] (3) adding the nano-silicon ...

Embodiment 3

[0046] This embodiment provides a method for preparing a conductive polymer-coated silicon composite carbon nanotube negative electrode material, which includes the following steps:

[0047] (1) Disperse elemental silicon (D50=7 micron, purity 99.95%, iron content<120ppm) in water, grind through sand mill 3h, obtain nano-silicon dispersion liquid, silicon particle diameter in the described nano-silicon dispersion liquid is D50= 500nm;

[0048] (2) get emulsifier dodecylbenzenesulfonic acid DBSA (also be the protonic acid dopant of polyaniline simultaneously) and emulsion dispersion agent dodecyl ammonium sulfate ALS respectively and dissolve in water, described emulsifier and described The molar ratio of the emulsion dispersant is 1:1, and then aniline monomer is added, the mass ratio of the aniline monomer to the emulsifier is 1:1.3, fully stirred and mixed uniformly, and the particle size of the emulsion droplet is 50-60nm aniline microemulsion;

[0049] (3) adding the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com