Sintering method of dense oxide ceramic body

A technology of dense oxide and sintering method, applied in the field of oxide ceramics, can solve the problem of inability to prepare high-density uniform ceramic films, and achieve the effects of reducing energy consumption, reducing production costs, and prolonging equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the oxide powder is SNDC (cerium oxide co-doped with samarium and neodymium), and the preparation method of the oxide powder is as follows:

[0038] (1) According to the stoichiometric ratio of the SNDC chemical formula, add corresponding doses of cerium acetate, neodymium nitrate, and samarium oxide into the ball mill tank, then add citric acid crop phase stabilizer and powder morphology control agent, and planetary ball mill for 8 hours , get slurry;

[0039] (2) Move the slurry obtained in step (1) into an oven and dry at 120°C;

[0040] (3) Put the dried product obtained in step (2) into a muffle furnace, and perform calcination treatment at 950° C. to obtain SNDC powder;

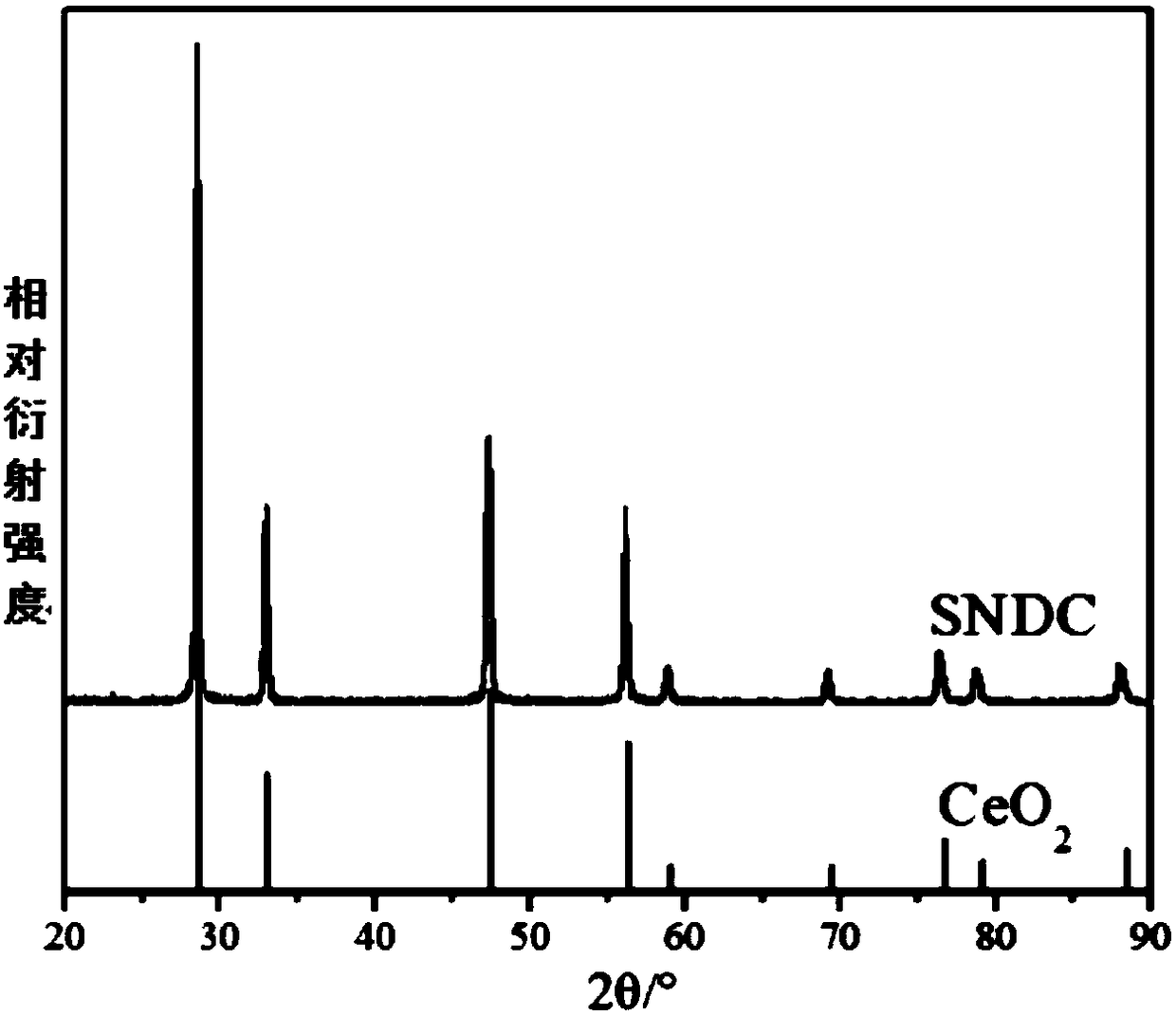

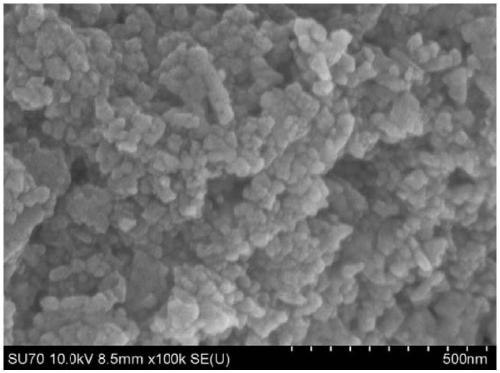

[0041] The XRD spectrum of the SNDC powder is as follows figure 1 As shown, it can be seen that the phase of the SNDC powder prepared by the above method is single, and the doping elements are solid-dissolved into the cerium oxide lattice. The SEM photo of the SNDC powder is ...

Embodiment 2

[0056] In this example, the oxide powder is exactly the same as that in Example 1, and its preparation method is also exactly the same as that in Example 1.

[0057] Utilize this SNDC powder to prepare ceramic film, specifically as follows:

[0058] (1) Using alcohol as the dispersion medium, the SNDC nano powder is ball-milled and dispersed for 16 to 20 hours;

[0059] (2) Add 0.5 to 2 times terpineol of the mass of the powder to the dispersed powder in step (1), and mix it by ball milling for 3 to 6 hours; then add EC (ethyl cellulose) with 2% of the mass of the powder solution, continue ball milling for 4 hours to obtain slurry;

[0060] (3) Coating the slurry in step (2) by screen printing on a sintered non-shrinkable YSZ (yttria-stabilized zirconia) flat substrate at 1300° C. to form a uniform film green body;

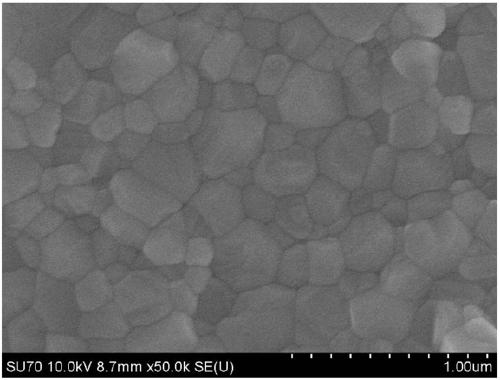

[0061] (4) Put the film blank obtained in step (3) together with the substrate into a muffle furnace for progressive sintering, that is, heat up to 750°C at a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com