A MoO3/rGO-N nano composite material and a preparation method and application thereof

A composite material and mixed solution technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unfavorable chemical bonds, failure to reach composite materials, etc., achieve good electrical conductivity, improve electrical conductivity Performance, effect of short electron transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

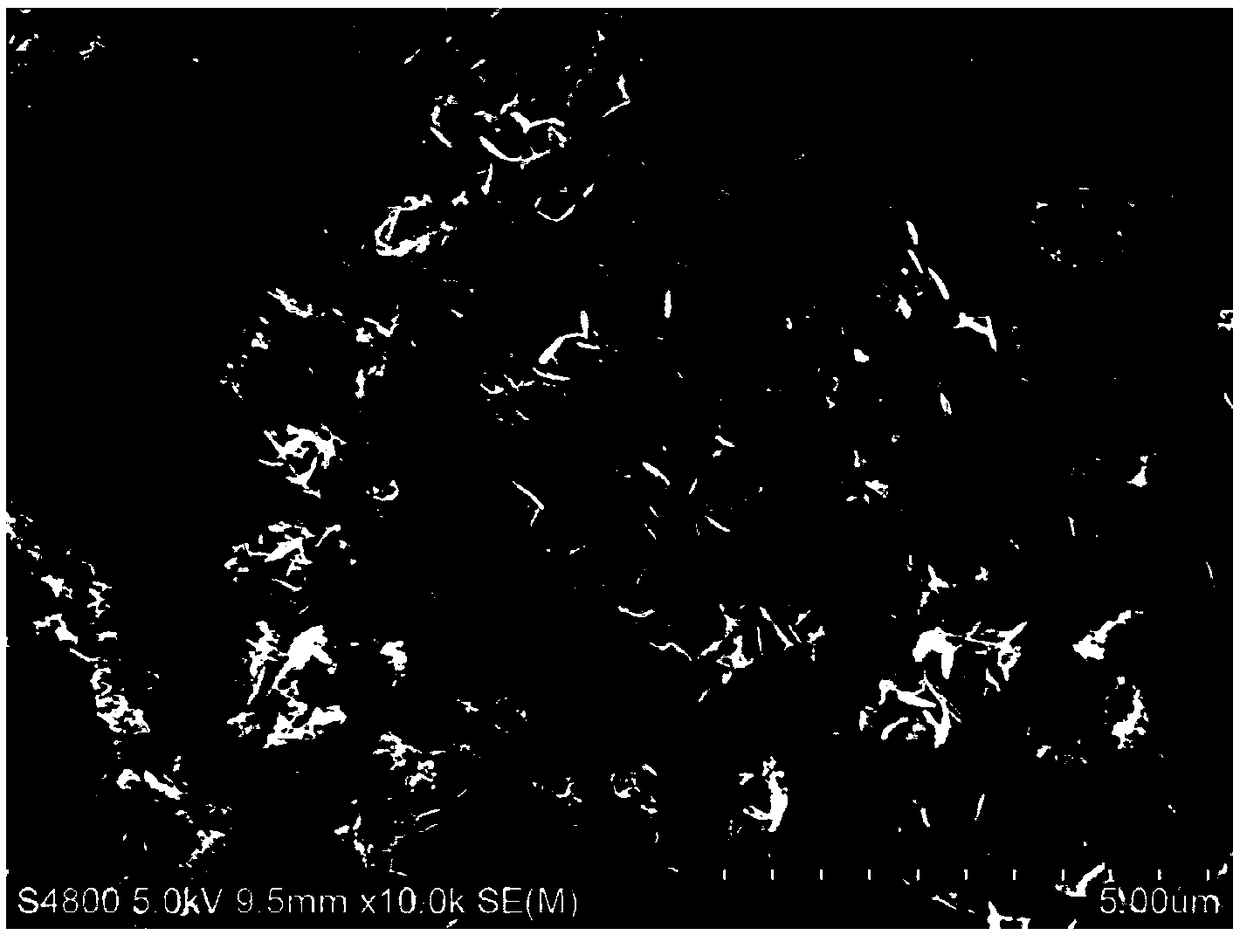

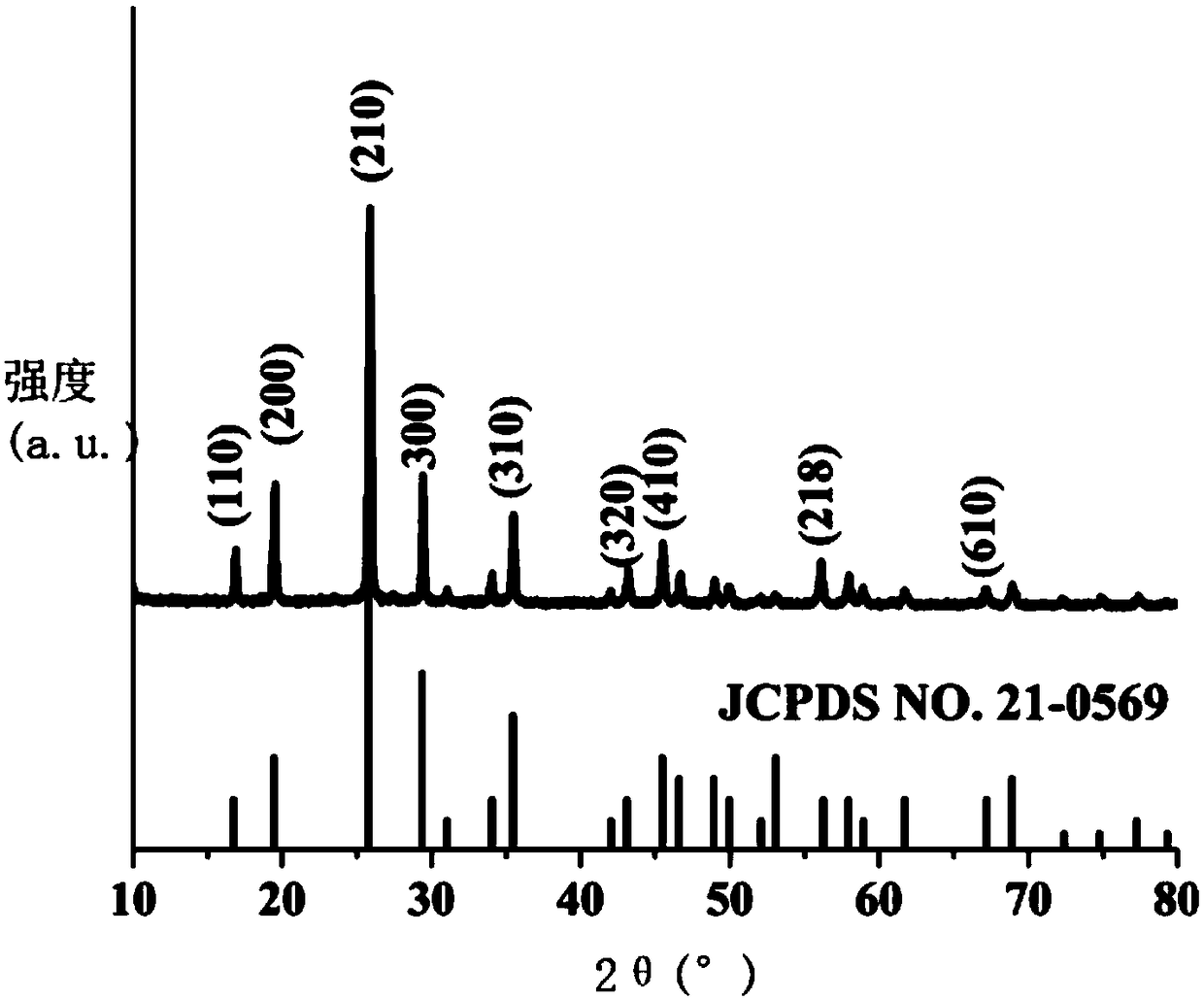

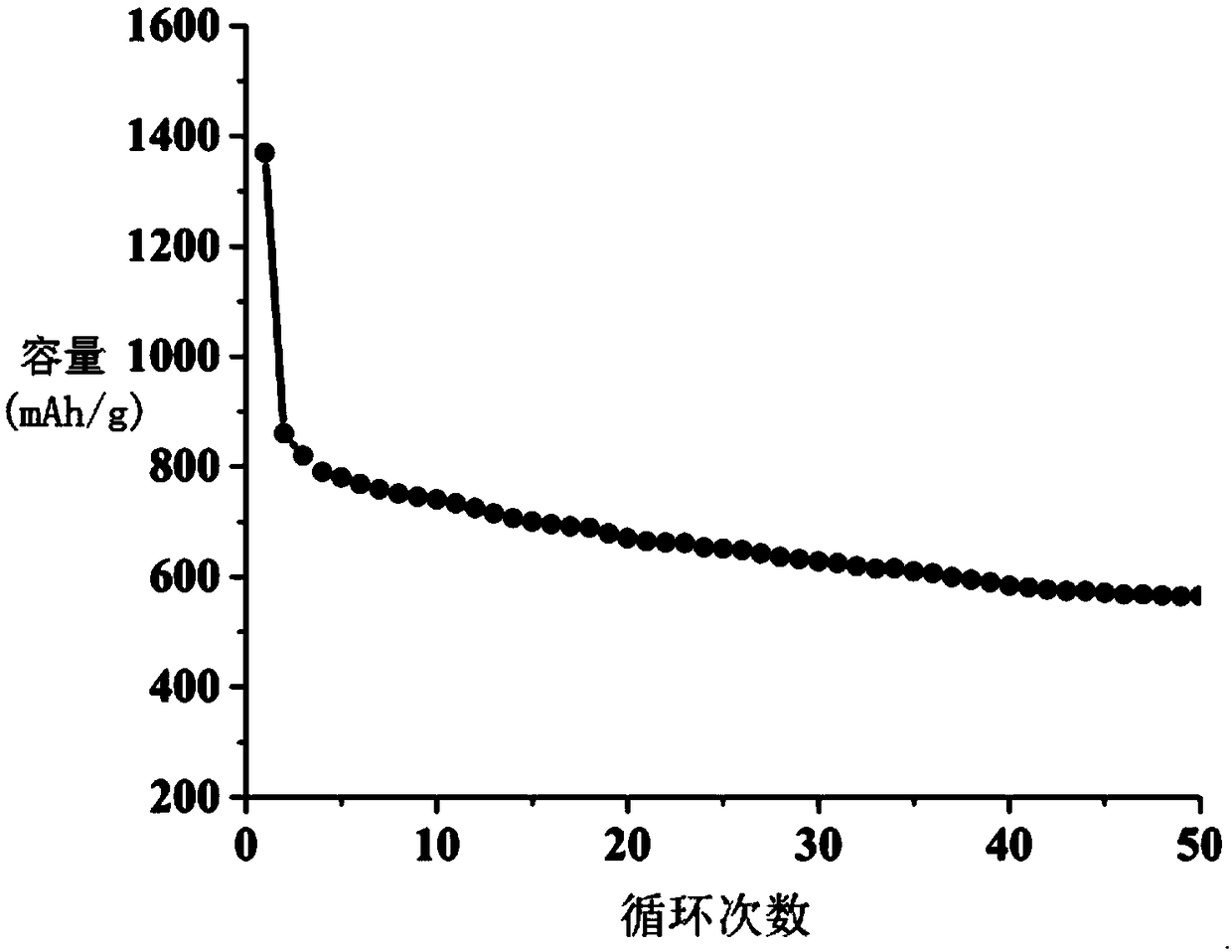

[0033] This embodiment provides a kind of MoO 3 / rGO-N composite material, and this kind of MoO 3 / rGO-N composites preparation method.

[0034] MoO described in this example 3 / rGO-N composites including nitrogen-doped redox graphene and flake-like MoO grown on the surface of nitrogen-doped redox graphene 3 , the composite material has a three-dimensional porous structure, and the specific preparation steps are as follows:

[0035] (1) Preparation of graphene oxide (GO): 5 g of natural graphite powder was added to 150 mL of concentrated sulfuric acid (w=98%), and 3.75 g of sodium nitrate was added under stirring at room temperature. Under vigorous stirring, slowly add 20g of potassium permanganate, keeping the temperature of the suspension below 20°C, then transfer the reaction system to room temperature, and stir for about 20h to form a thick slurry. Under the condition of constant stirring, slowly add 640mL of deionized water, then slowly add 30mL of hydrogen peroxide (...

Embodiment 2

[0042] This embodiment provides a kind of MoO 3 / rGO-N composite material, and this kind of MoO 3 / rGO-N composites preparation method.

[0043] MoO described in this example 3 / rGO-N composites including nitrogen-doped redox graphene and flake-like MoO grown on the surface of nitrogen-doped redox graphene 3 , the composite material has a three-dimensional porous structure, and the specific preparation steps are as follows:

[0044] (1) The preparation of graphene oxide (GO) is the same as in Example 1.

[0045] (2) Add 125mg GO to 50ml deionized water, stir magnetically for 30min and sonicate for 6h (control the water temperature below 40°C) to completely disperse graphene oxide in the aqueous solution. Subsequently, 0.75 g of sodium molybdate and 3.75 g of ammonium chloride were added thereto, and heated and stirred in an oil bath at 120° C. for 4 h. The resulting mixed solution was transferred to a reaction kettle and reacted at 180°C for 20 hours. After the reaction k...

Embodiment 3

[0048] This embodiment provides a kind of MoO 3 / rGO-N composite material, and this kind of MoO 3 / rGO-N composites preparation method.

[0049] MoO described in this example 3 / rGO-N composites including nitrogen-doped redox graphene and flake-like MoO grown on the surface of nitrogen-doped redox graphene 3 , the composite material has a three-dimensional porous structure, and the specific preparation steps are as follows:

[0050] (1) The preparation of graphene oxide (GO) is the same as in Example 1.

[0051] (2) Add 125mg GO to 50ml deionized water, stir magnetically for 30min and sonicate for 6h (control the water temperature below 40°C) to completely disperse graphene oxide in the aqueous solution. Subsequently, 0.75 g of potassium molybdate and 3.75 g of ammonium chloride were added thereto, and heated and stirred in an oil bath at 120° C. for 4 h. The resulting mixed solution was transferred to a reaction kettle and reacted at 180°C for 20 hours. After the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com