Comfortable Flame Retardant Fabric and Its Processing Technology

A processing technology and fabric technology, which is applied in the field of flame-retardant fabrics and their processing techniques, can solve the problem that flame-retardant fabrics cannot meet the flame-retardant function and comfortable wearability at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

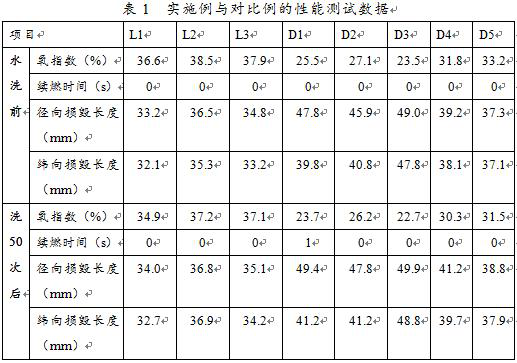

Examples

preparation example 1

[0064] Preparation Example 1 Flame Retardant Cotton Fiber

[0065] Use potassium hydroxide with a mass fraction of 9% and urea with a mass fraction of 9% as a mixed solution, soak ordinary cotton fibers for 6 hours, take out, wash with water until neutral, and dry;

[0066] The dried cotton fiber is dipped in the zinc oxide colloid, and then gel aging and supercritical drying are carried out to obtain the flame-retardant cotton fiber loaded with nano-zinc oxide, and the loading amount of nano-zinc oxide is 14% by mass. %. Among them, the aging time of the gel is 2-10 hours, and the super-near drying conditions are 50-60°C and 20 MPa.

preparation example 2

[0067] Preparation Example 2 Flame Retardant Polyester Fiber

[0068] Preparation of liquid containing flame retardant: take nano-talc powder and evenly disperse it in the mixed liquid of amino organosilicon quaternary ammonium salt, ethanol and water. Among them, in terms of mass percentage, talc is 25%, quaternary ammonium salt is 25%, ethanol is 10%, and water is 40%.

[0069] The ordinary polyester fiber is immersed in the above-mentioned liquid containing the flame retardant, and after soaking, it is taken out and dried to obtain a composite material of nano-talc and polyester, which is a flame retardant polyester fiber.

preparation example 3

[0070] Preparation Example 3 Flame Retardant Acrylic Fiber

[0071] Using anhydrous DMF as a solvent, under ice bath conditions, add acryloyl chloride dropwise to the nano-silica containing hydroxyl groups on the surface, and purify by centrifugation to obtain an intermediate product;

[0072] Take acrylonitrile, methyl acrylate, sodium allyl sulfonate and intermediate products as monomers (the mass ratio of materials in the monomers is 92:3.5:0.5:4), use AIBN as initiator, and use sodium thiocyanate as the The aqueous solution is used as a solvent, thiourea dioxide is used as a light coloring agent, isopropanol is used as a modifier, and an aqueous solution of sodium thiocyanate with a concentration of 55% is used as a solvent to react to obtain modified polyacrylonitrile, and the modified polyacrylonitrile is wetted. Method spinning to obtain flame retardant acrylic fiber.

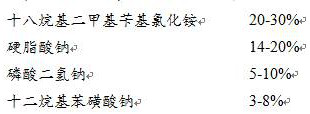

[0073] Among them, the mass percentage of each feeding is:

[0074] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com