Surface treatment liquid and surface treatment device for 3D printing stainless steel parts

A surface treatment liquid, 3D printing technology, applied in machine tools suitable for grinding workpiece edges, surface polishing machine tools, polishing compositions containing abrasives, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

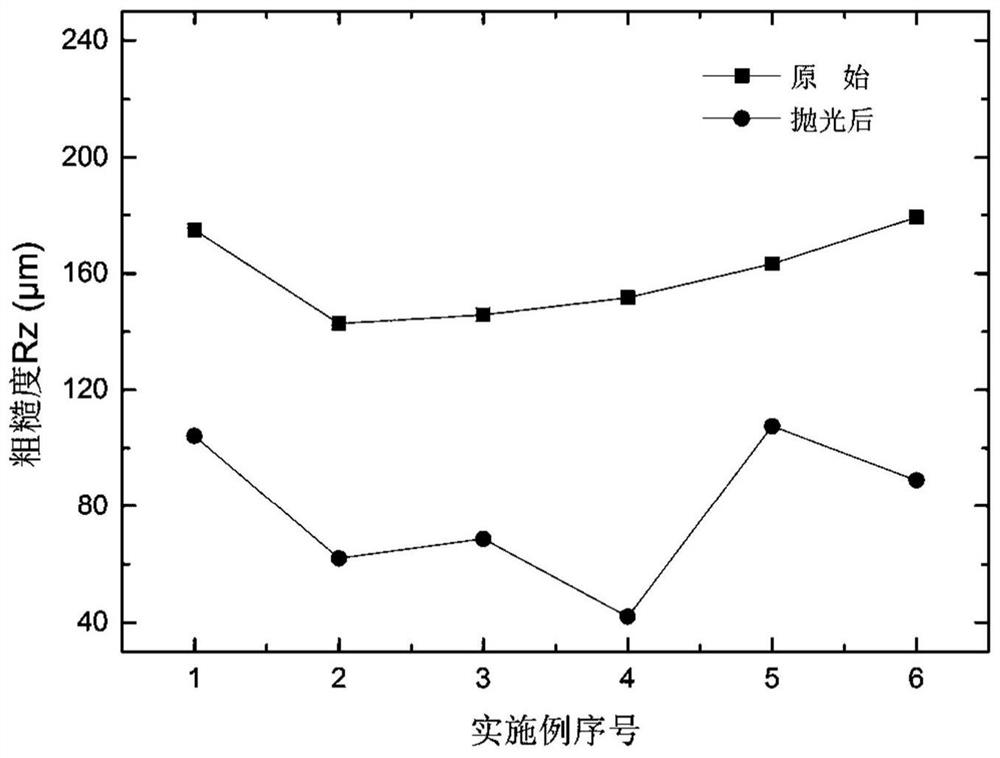

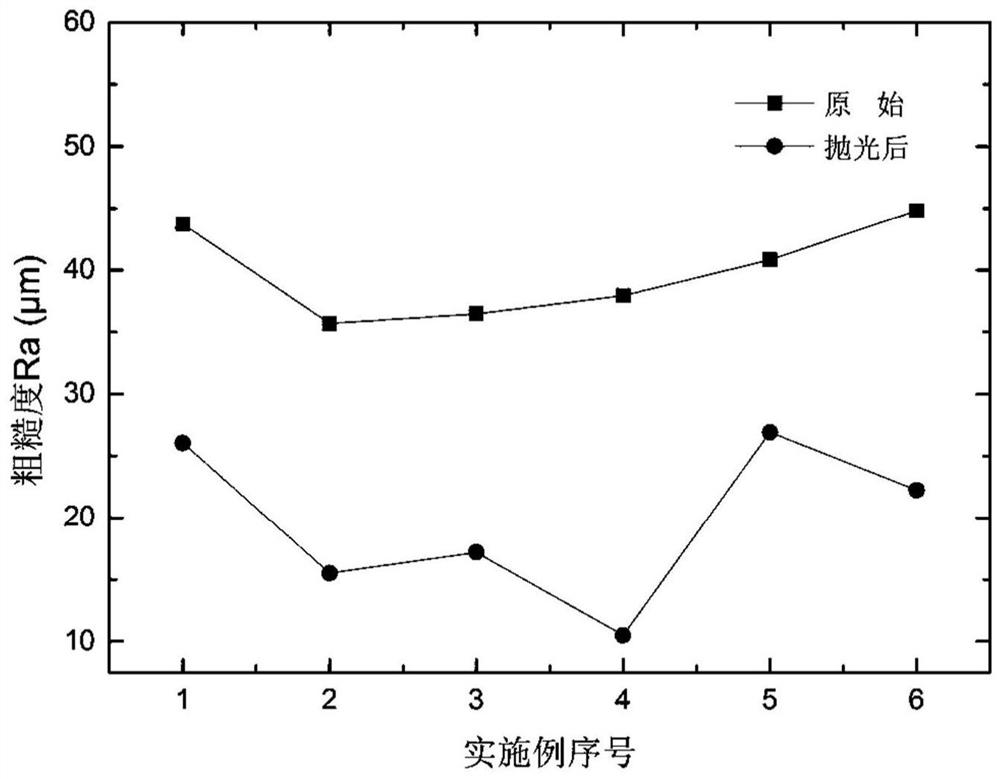

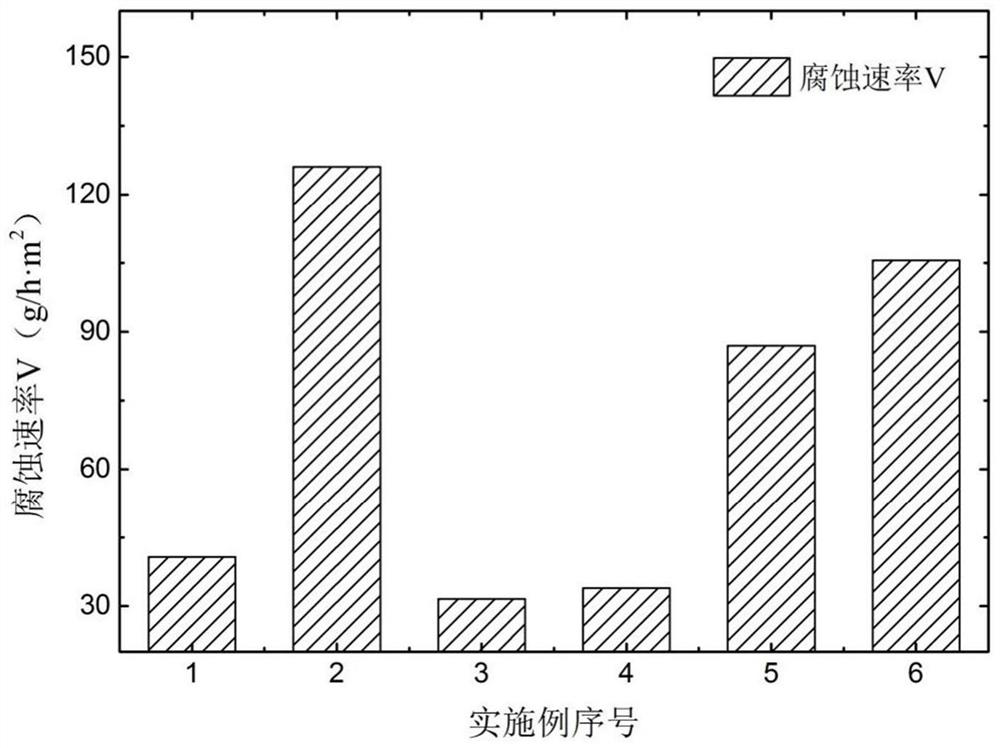

Embodiment 1

[0054] A surface treatment solution for 3D printing stainless steel parts, including alkaline cooking solution, pickling solution and chemical polishing solution:

[0055] The mass fraction ratio of sodium hydroxide, nitrate and chloride ion-containing salt in the soda cooking liquid is as follows: 10:5:0.15.

[0056] The nitrate is composed of sodium nitrate and sodium nitrite, and the mass-number ratio of sodium nitrate and sodium nitrite is 3:1.

[0057] The chloride-ion-containing salt is composed of sodium chloride and ferric chloride, and the mass-number ratio of sodium chloride and ferric chloride is 2.5:1.

[0058] The mass-number ratio of hydrochloric acid, sodium chloride, ferric chloride and corrosion inhibitor in the pickling solution is: 15: 3.2: 0.6: 0.2.

[0059] The corrosion inhibitor is composed of potassium iodide and rhodin, and the mass-number ratio of potassium iodide and rhodin is 2:1.

[0060] The chemical polishing liquid is made up of nano-scale sil...

Embodiment 2

[0083] Embodiment 2 comprises the solution preparation step and surface treatment device of embodiment 1, and the surface treatment liquid of embodiment 2 comprises alkali boiling liquid, pickling liquid and chemical polishing liquid:

[0084] The ratio in parts by mass of sodium hydroxide, nitrate and salt containing chloride ions in the caustic boiling liquid is as follows: 18:3:0.05.

[0085] The nitrate is composed of sodium nitrate and sodium nitrite, and the mass-number ratio of sodium nitrate and sodium nitrite is 5:1.

[0086] The chloride-ion-containing salt is composed of sodium chloride and ferric chloride, and the mass-number ratio of sodium chloride and ferric chloride is 1:1.

[0087] The mass-number ratio of hydrochloric acid, sodium chloride, ferric chloride and corrosion inhibitor in the pickling liquid is: 15:4:0.8:0.2.

[0088] The corrosion inhibitor is composed of potassium iodide and rhodin, and the mass-number ratio of potassium iodide and rhodin is 3:1...

Embodiment 3

[0101] Embodiment 3 comprises the solution preparation step and surface treatment device of embodiment 1, and the surface treatment liquid of embodiment 3 comprises alkali boiling liquid, pickling liquid and chemical polishing liquid:

[0102] The ratio in parts by mass of sodium hydroxide, nitrate and salt containing chloride ions in the soda cooking liquid is as follows: 15:5:0.1.

[0103] The nitrate is composed of sodium nitrate and sodium nitrite, and the mass-number ratio of sodium nitrate and sodium nitrite is 5:1.

[0104]The chloride-ion-containing salt is composed of sodium chloride and ferric chloride, and the mass-number ratio of sodium chloride and ferric chloride is 2.5:1.

[0105] The mass-number ratio of hydrochloric acid, sodium chloride, ferric chloride and corrosion inhibitor in the pickling solution is: 20:3.2:0.8:0.1;

[0106] The corrosion inhibitor is composed of potassium iodide and rhodin, and the mass-number ratio of potassium iodide and rhodin is 2:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com