Method for preparing load type activated carbon from furfural residues and application of load type activated carbon

An activated carbon and supported technology, which is applied in the field of preparing supported activated carbon, can solve the problems such as the inability of activated carbon to adsorb metal cations, low loading, residual salt solution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

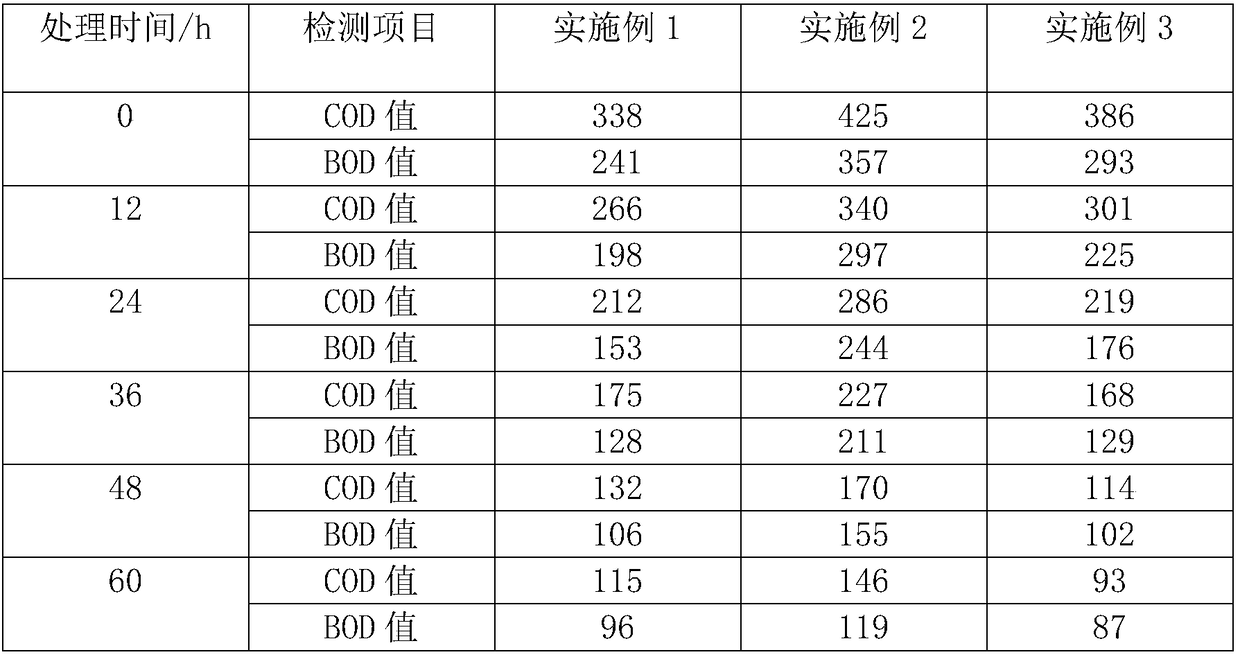

Embodiment 1

[0022] Embodiment 1 prepares supported activated carbon

[0023] S1: carbonization: under nitrogen atmosphere, carbonize furfural residue at 250°C for 4 hours to obtain black carbon residue;

[0024] S2: Activation: Mix and grind black carbon residue, potassium hydroxide, and potassium bicarbonate at a mass ratio of 1:2:1, and raise the temperature to 400°C at a rate of 6°C / min under nitrogen atmosphere, activate for 1h, 0.2mol / pickling with L hydrochloric acid solution until the pH is neutral, and drying at 60°C to obtain activated carbon;

[0025] S3: Loading: The mass ratio of titanium oxide, zinc oxide, nickel oxide, and aluminum oxide is 1:0.5:0.2:0.1, and the composite nano-metal oxide with an average particle size of 10nm is dispersed in the average particle size at a mass ratio of 0.01:1. A microcrystalline cellulose sol with a diameter of 40nm and a viscosity ≧800mPa·s is used to obtain a mixed coating sol. The composite nano-metal oxide is composed of titanium oxid...

Embodiment 2

[0026] Embodiment 2 prepares supported activated carbon

[0027] Preparation method is with embodiment 1, difference is:

[0028] S1: Carbonization: carbonization temperature and time are 280°C and 56h respectively;

[0029] S2: Activation: The mass ratio of black carbon residue, potassium hydroxide, and potassium bicarbonate is 1:3:1.5, the heating rate is 10°C / min, the activation temperature and time are 450°C and 2h, respectively, and the concentration of hydrochloric acid solution is 0.6mol / L;

[0030] S3: Loading: the mass ratio of titanium oxide, zinc oxide, nickel oxide, and aluminum oxide is 1:1.2:0.4:0.15, the mass ratio of composite nano-metal oxide to microcrystalline cellulose sol is 0.06:1, activated carbon and mixed package The mass ratio of coating sol is 1:1.25, the average particle size of composite nano metal oxide is 20nm, the average particle size of microcrystalline cellulose is 50nm, the impregnation adsorption pressure and time are 6MPa and 2h respect...

Embodiment 3

[0031] Embodiment 3 prepares supported activated carbon

[0032] Preparation method is with embodiment 1, difference is:

[0033] S1: Carbonization: carbonization temperature and time are 300°C and 6h respectively;

[0034] S2: Activation: The mass ratio of black carbon residue, potassium hydroxide, and potassium bicarbonate is 1:4:2, the heating rate is 15°C / min, the activation temperature and time are 500°C and 3h, respectively, and the concentration of hydrochloric acid solution is 1mol / min. L;

[0035] S3: Loading: the mass ratio of titanium oxide, zinc oxide, nickel oxide, and aluminum oxide is 1:2:0.6:0.2, the mass ratio of composite nano-metal oxide to microcrystalline cellulose sol is 0.1:1, activated carbon and mixed package The mass ratio of coating sol is 1:1.5, the average particle size of composite nano metal oxide is 30nm, the average particle size of microcrystalline cellulose is 60nm, the impregnation adsorption pressure and time are 8MPa and 3h respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com