Photocatalytic separation film for water treatment and preparation method

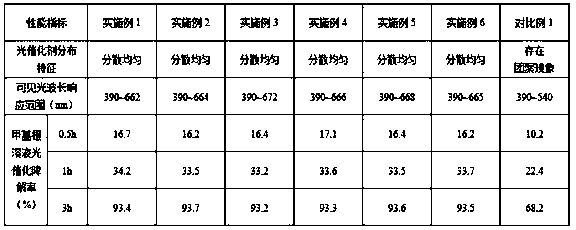

A photocatalytic separation membrane and water treatment technology, applied in the field of water treatment, can solve the problems of poor photocatalyst dispersibility, unsatisfactory water treatment effect, low photocatalytic efficiency, etc., and achieves high visible light utilization rate, good dispersion, and photocatalysis Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add p-tert-butylphenol and catalyst sodium hydroxide to diphenyl ether, then add sublimed sulfur, tetrabutyl titanate, ammonium carbonate, zinc sulfate, stir under nitrogen atmosphere, and gradually heat up to reflux reaction Cool to room temperature after 5.5h, then wash with sulfuric acid solution and ethanol solution successively, then purify with chloroform, and dry in vacuum to prepare loaded nano-TiO 2and nano-ZnO p-tert-butylthiocalix[4]arene; the heating rate is 1.2°C / min, and the reflux temperature is 230°C; the mass concentration of the sulfuric acid solution is 5%, and the mass concentration of the ethanol solution is 86%; The temperature of vacuum drying is 44° C., and the time is 7 hours; the parts by weight of each raw material are 29 parts by weight of p-tert-butylphenol, 4 parts by weight of sodium hydroxide, 11 parts by weight of sublimed sulfur, 3 parts by weight of tetrabutyl titanate, 1 weight part of ammonium carbonate, 2 weight parts of zinc su...

Embodiment 2

[0041] (1) Add p-tert-butylphenol and catalyst sodium hydroxide to diphenyl ether, then add sublimed sulfur, tetrabutyl titanate, ammonium carbonate, zinc sulfate, stir under nitrogen atmosphere, and gradually heat up to reflux reaction Cool to room temperature after 5h, then wash with sulfuric acid solution and ethanol solution successively, then purify with chloroform, and dry in vacuum to prepare loaded nano-TiO 2 and nano-ZnO p-tert-butylthiocalix[4]arene; the heating rate is 0.5°C / min, and the reflux temperature is 210°C; the mass concentration of the sulfuric acid solution is 4%, and the mass concentration of the ethanol solution is 82%; The temperature of vacuum drying is 42° C., and the time is 7 hours; the parts by weight of each raw material are 29 parts by weight of p-tert-butylphenol, 4 parts by weight of sodium hydroxide, 11 parts by weight of sublimed sulfur, 3 parts by weight of tetrabutyl titanate, 1 weight part of ammonium carbonate, 1 weight part of zinc sulf...

Embodiment 3

[0046] (1) Add p-tert-butylphenol and catalyst sodium hydroxide to diphenyl ether, then add sublimed sulfur, tetrabutyl titanate, ammonium carbonate, zinc sulfate, stir under nitrogen atmosphere, and gradually heat up to reflux reaction After 6h, it was cooled to room temperature, and then washed with sulfuric acid solution and ethanol solution in turn, then purified with chloroform, and dried in vacuum to obtain the loaded nano-TiO 2 and nano-ZnO p-tert-butylthiocalix[4]arene; the heating rate is 1.5°C / min, and the reflux temperature is 230°C; the mass concentration of the sulfuric acid solution is 5%, and the mass concentration of the ethanol solution is 88%; The temperature of vacuum drying is 48° C., and the time is 6 hours; the parts by weight of each raw material are 31 parts by weight of p-tert-butylphenol, 4 parts by weight of sodium hydroxide, 12 parts by weight of sublimed sulfur, 4 parts by weight of tetrabutyl titanate, 2 parts by weight of ammonium carbonate, 2 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com