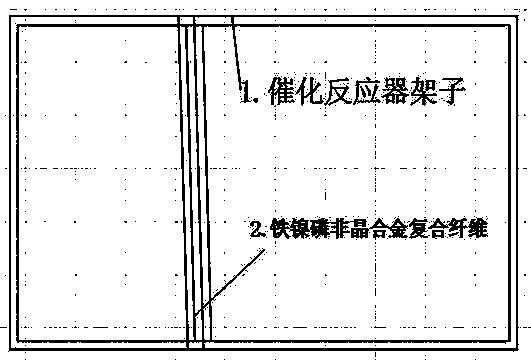

Fe-Ni-P amorphous alloy catalytic reactor and production method thereof

A catalytic reactor, amorphous alloy technology, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical processes, etc., can solve the problems of small reactor area and low yield, etc. Achieving the effect of large catalytic area and improved possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Forming process of Fe-Ni-P amorphous alloy / polypropylene composite fiber

[0032] (1) choose φ 0.05 mm polypropylene fiber, first use sodium hydroxide solution for chemical degreasing;

[0033] (2) Coarsening of fibers after degreasing, the proportion of the coarsening aqueous solution is 80g / L chromic anhydride, 250ml / L sulfuric acid, the roughening treatment temperature is 70°C, and the roughening treatment time is 8 minutes;

[0034] (3) Sensitization of polypropylene fibers, the solution composition is tin chloride 8g / L, hydrochloric acid 40ml / L, and the sensitization treatment time is 1 min;

[0035] (4) Silver nitrate and ammonia solution are used to activate the fiber surface, and the activated fiber is reduced by formaldehyde solution;

[0036] (5) Electroless nickel-phosphorus alloy plating of fibers, the solution composition is: nickel chloride 0.1mol / L, tartaric acid 0.08 mol / L, sodium hypophosphite 0.1mol / L, potassium iodide 3g / L, sodium bor...

Embodiment 2

[0039] Embodiment 2: the forming process of Fe-Ni-P amorphous alloy / nylon composite fiber

[0040] (1) choose φ 0.2mm nylon fiber, first use sodium hydroxide solution for chemical degreasing;

[0041] (2) Coarsening of fibers after degreasing, the proportion of the coarsening aqueous solution is 80g / L chromic anhydride, 250ml / L sulfuric acid, the roughening treatment temperature is 70°C, and the roughening treatment time is 8 minutes;

[0042] (3) Sensitization of polypropylene fibers, the solution composition is tin chloride 8g / L, hydrochloric acid 40ml / L, and the sensitization treatment time is 1 min;

[0043] (4) Silver nitrate and ammonia solution are used to activate the fiber surface, and the activated fiber is reduced by formaldehyde solution;

[0044] (5) Electroless nickel-phosphorus alloy plating of fibers, the solution composition is: nickel chloride 0.1mol / L, tartaric acid 0.1mol / L, sodium hypophosphite 0.1mol / L, potassium iodide 3 g / L, sodium borohydride 2g / L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com