Modification method for carrying out gaseous polyfluoride grafting on surfaces of membrane type artificial lungs by utilizing low-temperature plasma technology

A low-temperature plasma and gas-phase grafting technology, which is applied in the field of modification of polyfluoride gas-phase grafting, can solve the problem of not being able to completely suppress the rejection reaction of the human body, injecting a large amount of anticoagulant, and poor blood compatibility of polymer membranes, etc. problems, to achieve the effects of excellent gas permeability, improved blood compatibility, and good gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

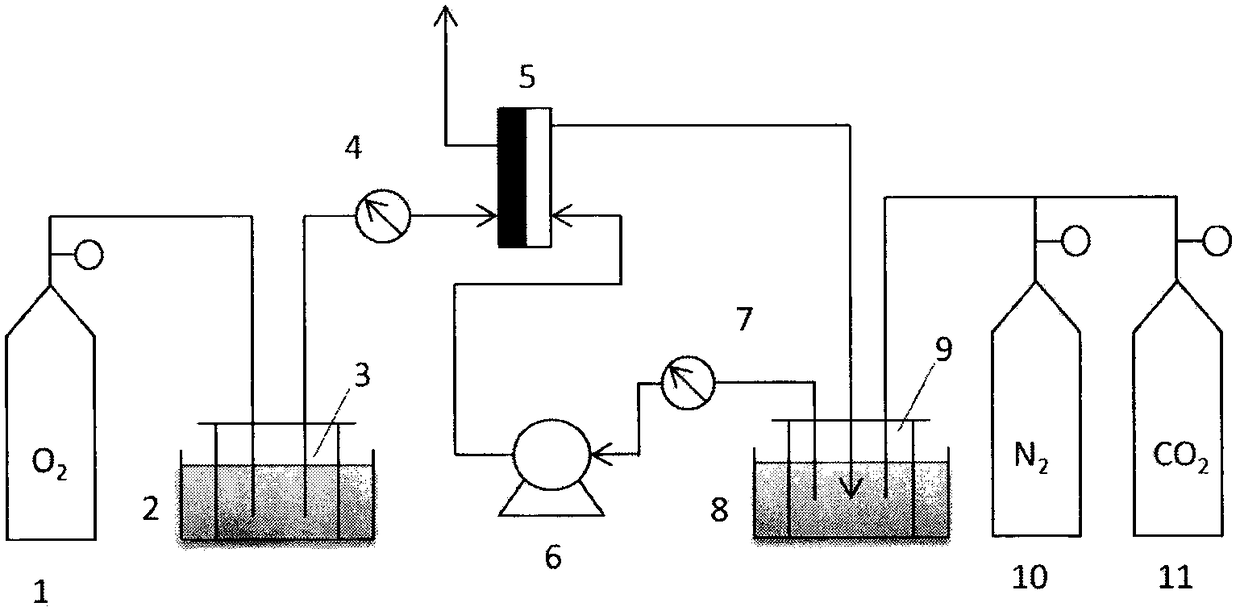

[0028] Clean the poly-4-methyl-1-pentene hollow fiber membrane with deionized water and dry it for 24 hours, then put it into the cavity of the plasma treatment instrument and fix it slightly, and use a vacuum pump to heat the cavity of the gas phase grafting instrument. The operating pressure in the furnace is controlled at about 5Pa, and neon gas (Ne) is introduced for surface activation. The discharge pressure is 40Pa, the irradiation power is 140W, and after the irradiation time is 160s, the plasmaization operation is stopped, and the vacuum pump pumps out the gas in the cavity of the low-temperature plasma processor, and replaces the gas in the cavity with nitrogen. Repeat the above operation three times

[0029] Pour perfluorooctyl ethyl alcohol into the heating cavity of the gas phase grafting instrument, connect the cavity of the low temperature plasma treatment instrument and the heating cavity of the gas phase grafting instrument, and open the valve on the gas phase ...

specific Embodiment 2

[0031] Clean the poly-4-methyl-1-pentene hollow fiber membrane with deionized water and dry it for 24 hours, then put it into the cavity of the plasma treatment instrument and fix it slightly, and use a vacuum pump to heat the cavity of the gas phase grafting instrument. The operating pressure in the furnace is controlled at about 5Pa, and neon gas (Ne) is introduced for surface activation. The discharge pressure is 45Pa, the irradiation power is 150W, and after the irradiation time is 180s, the plasmaization operation is stopped, and the vacuum pump pumps out the gas in the cavity of the low-temperature plasma processor, and replaces the gas in the cavity with nitrogen. Repeat the above operation three times

[0032] Pour perfluoroalkyl ethyl alcohol into the heating cavity of the gas-phase grafting instrument, connect the cavity of the low-temperature plasma treatment instrument and the heating cavity of the gas-phase grafting instrument, and open the valve on the gas-phase ...

specific Embodiment 3

[0034] Clean the poly-4-methyl-1-pentene hollow fiber membrane with deionized water and dry it for 24 hours, then put it into the cavity of the plasma treatment instrument and fix it slightly, and use a vacuum pump to heat the cavity of the gas phase grafting instrument. The operating pressure in the furnace is controlled at about 5Pa, and neon gas (Ne) is introduced for surface activation. The discharge pressure is 35Pa, the irradiation power is 120W, and after the irradiation time is 180s, the plasmaization operation is stopped, and the vacuum pump pumps out the gas in the cavity of the low-temperature plasma processor, and replaces the gas in the cavity with nitrogen. Repeat the above operation three times

[0035] Pour tetrafluoropropanol into the heating cavity of the gas-phase grafting instrument, connect the cavity of the low-temperature plasma treatment instrument and the heating cavity of the gas-phase grafting instrument, open the valve on the gas-phase connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com