Probiotic formulated milk powder and preparation method thereof

A technology of formula milk powder and probiotics, applied in dairy products, milk preparations, Streptococcus/Lactococcus, etc., can solve the problems of single strain, lack of flavor, and monotonous taste, and achieve the goal of promoting intestinal peristalsis and relieving diarrhea. Symptoms, toxin-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The probiotic formula milk powder of this embodiment includes milk powder raw materials, milk powder auxiliary materials and nutritional fortifiers. In this embodiment, the number of viable bacteria is preferably greater than or equal to 1×10 9 cfu / 100g milk powder.

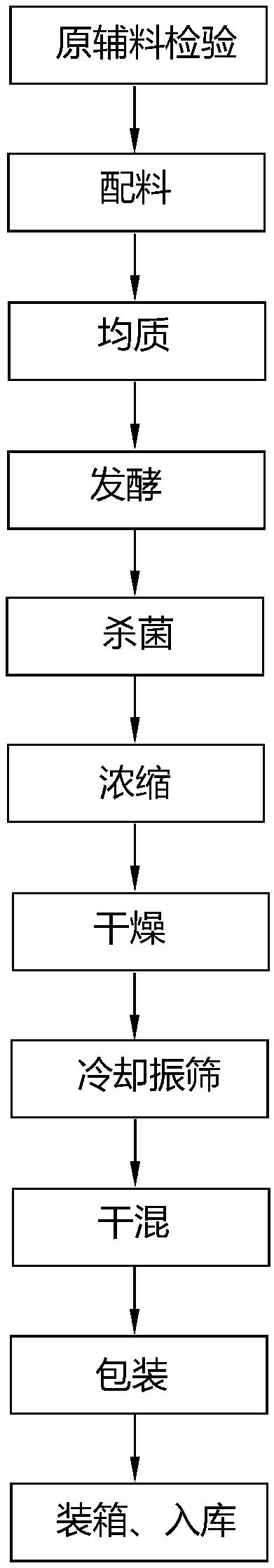

[0023] Such as figure 1 As shown, the specific manufacturing method of probiotic formula milk powder is as follows:

[0024] (1) Inspection of raw and auxiliary materials. The purchased raw and auxiliary materials shall be inspected according to the acceptance standards of raw and auxiliary materials, especially the detection of antibiotics. Unqualified raw and auxiliary materials shall not be used. The probiotics are kept frozen in a special freezer to ensure their activity.

[0025] (2) Ingredients, mix 4200kg of raw milk (or raw goat milk) or 475kg of whole milk powder (or whole goat milk powder), with 250kg of desalted whey powder, 75kg of whey protein powder, 50kg of refined vegetable oil, 50kg of ...

Embodiment 2

[0031] The rest are the same as in Example 1, except that the total amount of fermented probiotics added is 1.5×10 9 cfu / 100g, the total amount of dry mixed probiotics added is 1×10 8 cfu / 100g.

Embodiment 3

[0033] All the other are the same as in Example 1, except that Bifidobacterium adolescent is used to replace Bifidobacterium animalis Bb-12, Bifidobacterium lactis, Lactobacillus acidophilus, Lactobacillus plantarum, Bifidobacterium amphibian, Lactobacillus rhamnosus , Lactobacillus casei, and Bifidobacterium infantis.

[0034] To sum up, the present invention discloses a probiotic formula milk powder, in which ten kinds of active probiotic bacteria are added, and the pre-fermentation technology is used to make the product have a unique taste and smell, which is more popular with consumers; dry mixing The probiotics in it can relieve diarrhea symptoms; alleviate lactose intolerance; prevent reproductive system infection; enhance human immunity; promote intestinal and digestive system health. Contribute to human health.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com