Method of recovering compound fertilizer from polishing cleaning wastewater in aluminum industry and system configuration

A technology for cleaning waste water and system configuration, which is applied in the field of aluminum processing, can solve the problems of high energy consumption, high treatment cost, and high cost in the three-acid evaporation process, and achieve saving energy consumption and environmental protection costs, reducing the amount of waste liquid recovery, Effect of low cost of waste liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

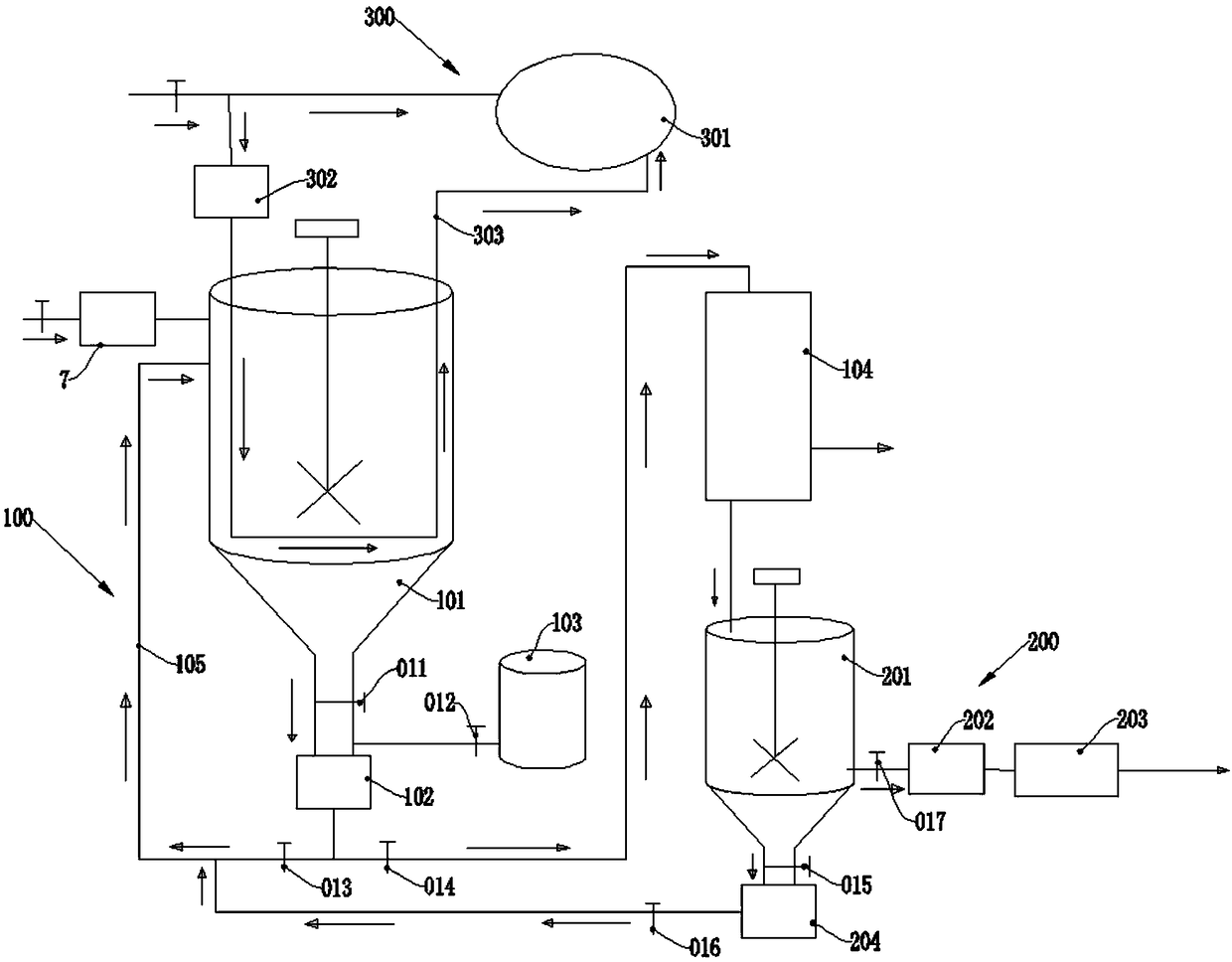

[0147] Embodiment 1 Recycling of aluminum phosphate and liquid N-P compound fertilizer.

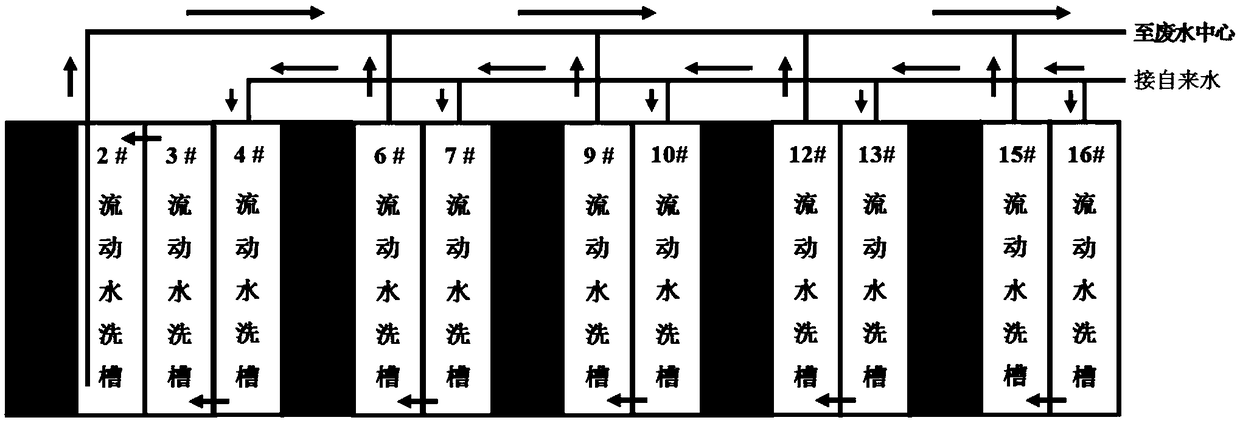

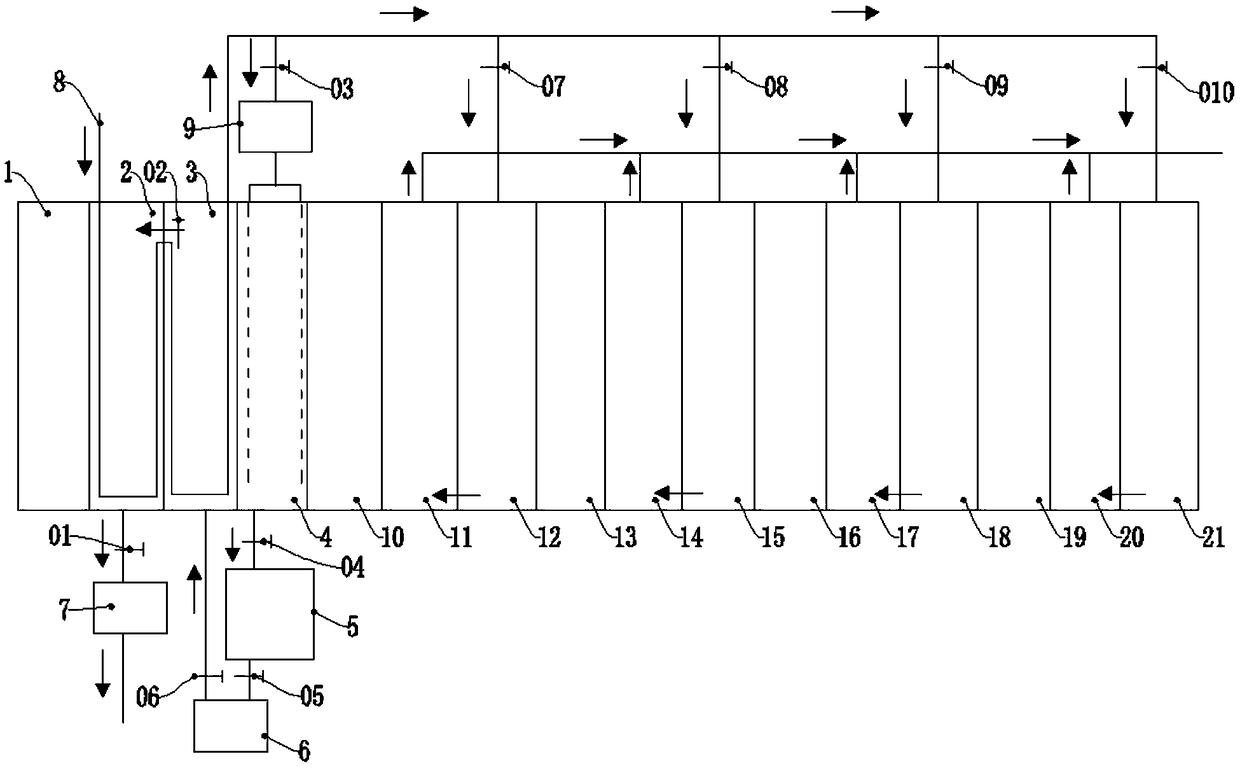

[0148] Polishing waste water interception: aluminum alloy enters polishing tank 1 and polishes for 20s-120s, then trickles for 20s; aluminum alloy enters first non-flowing washing tank 2, cleans for 60s, drips for 30s, first flowing washing tank 2 is provided with cooling pipe 8, The production temperature of the first flowing water washing tank 2 is controlled at ≤ 50°C; after that, the aluminum alloy enters the second non-flowing water washing tank 3, cleans for 60 seconds, and drips for 30 seconds; then enters the high-pressure atomizing spray tank 4 and sprays for 30 seconds. s, the spray water flows into the storage tank 5; the interception of the polishing liquid waste water is completed; when the water level in the first flowing water washing tank 2 drops, it is supplemented by the water in the second non-flowing water washing tank 3; when the second non-flowing water washing tank 3...

Embodiment 2

[0152] Example 2 Liquid N-P compound fertilizer concentrates the crystallization separation liquid to generate N-P compound fertilizer.

[0153] Get embodiment 1 when the bath liquid density of the first non-flowing washing tank reaches 1.29-1.31g / cm 3 When collecting the bath liquid and stopping the dosing when the pH value reached 6.5-7.5, 1000g of liquid N-P compound fertilizer was obtained. Concentrate and crystallize, dry and grind to obtain 453g of N-P compound fertilizer containing ammonium sulfate-ammonium phosphate-ammonium nitrate. The solid content of the liquid N-P compound fertilizer is 45.3%, and the water content is 54.7%.

Embodiment 3

[0154] Example 3 Liquid N-P compound fertilizer is mixed with bagasse (moisture content ≤ 10%) to produce granular organic-inorganic compound fertilizer.

[0155] Get embodiment 1 when the bath liquid density of the first non-flowing washing tank reaches 1.29-1.31g / cm 3 When collecting bath liquor and when the pH value reaches 6.5-7.5 and stops dosing, the obtained water content is 54.7% liquid N-P compound fertilizer 1000g, add dry and fresh distiller's grains 10g, gradually add dry powdery bagasse (moisture content ≤10%), until no water dripping, the dosage of bagasse (moisture content≤10%) is 250g, and the finished product is granular organic-inorganic compound fertilizer; in the retting factory area equipped with ventilation equipment, ferment for 60 days, and the compound fertilizer becomes black Black is the end point of ripening;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com