Adhesive for flame-retardant glass wool and preparation method of adhesive

A technology of adhesive and glass wool, applied in the direction of adhesive types, polyether adhesives, polymer adhesive additives, etc., can solve the problems affecting the flame retardancy of glass wool, achieve strong rigidity, improve resistance Combustibility, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

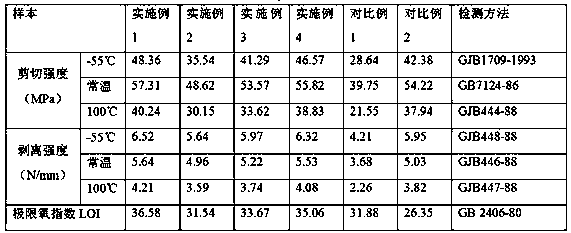

Examples

Embodiment 1

[0018] A flame-retardant adhesive for glass wool, prepared from the following raw materials in parts by weight: 60 parts of acrylonitrile-butadiene-styrene copolymer, 42 parts of polyarylether ether nitrile, 24 parts of phenolic resin, three 12 parts of ethylene propylene rubber, 9 parts of diethyl aminomalonate, 13 parts of inorganic flame retardant filler, 5 parts of epoxy soybean oil, 10 parts of alumina fiber, 4.5 parts of cosolvent, 6 parts of dimethylaminopropylamine, ten parts 12 parts of bromodiphenylethane, 22 parts of n-butanol.

[0019] The co-solvent is ethylene glycol butyl ether acetate and N,N-dimethylacetamide with a volume ratio of 5:2.

[0020] The inorganic flame retardant filler is white carbon black, kaolin, zinc borate and ammonium tripolyphosphate with a mass ratio of 3:2:5:7.

[0021] The preparation method of adhesive of the present invention comprises the following steps:

[0022] (1) Put acrylonitrile-butadiene-styrene copolymer, polyarylether ethe...

Embodiment 2

[0027] A flame-retardant adhesive for glass wool, prepared from the following raw materials in parts by weight: 50 parts of acrylonitrile-butadiene-styrene copolymer, 35 parts of polyarylether ether nitrile, 18 parts of phenolic resin, three 8 parts of ethylene propylene rubber, 6 parts of diethyl aminomalonate, 9 parts of inorganic flame retardant filler, 3 parts of epoxy soybean oil, 6 parts of alumina fiber, 3 parts of cosolvent, 4 parts of dimethylaminopropylamine, ten parts 7 parts of bromodiphenylethane, 15 parts of n-butanol.

[0028] The co-solvent is ethylene glycol butyl ether acetate and N,N-dimethylacetamide with a volume ratio of 5:1.

[0029] The inorganic flame retardant filler is white carbon black, kaolin, zinc borate and ammonium tripolyphosphate with a mass ratio of 2:1:4:5.

[0030] The preparation method of adhesive of the present invention comprises the following steps:

[0031] (1) Put acrylonitrile-butadiene-styrene copolymer, polyarylether ether nitr...

Embodiment 3

[0036] A flame-retardant adhesive for glass wool, prepared from the following raw materials in parts by weight: 55 parts of acrylonitrile-butadiene-styrene copolymer, 40 parts of polyarylether ether nitrile, 20 parts of phenolic resin, three 10 parts of ethylene propylene rubber, 8 parts of diethyl aminomalonate, 12 parts of inorganic flame retardant filler, 4 parts of epoxy soybean oil, 8 parts of alumina fiber, 4 parts of cosolvent, 5 parts of dimethylaminopropylamine, ten parts Bromodiphenylethane 10 parts, n-butanol 20 parts.

[0037] The co-solvent is ethylene glycol butyl ether acetate and N,N-dimethylacetamide with a volume ratio of 5:1.5.

[0038] The inorganic flame retardant filler is white carbon black, kaolin, zinc borate and ammonium tripolyphosphate with a mass ratio of 3:1:5:6.

[0039] The preparation method of adhesive of the present invention comprises the following steps:

[0040] (1) Put acrylonitrile-butadiene-styrene copolymer, polyarylether ether nitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com