Method for preparing cellulose and graphene compound short fibers

A graphene composite, cellulose technology, applied in the direction of single-component cellulose rayon, fiber chemical characteristics, spinning solution preparation, etc. Application and development of functional fibers, pressure resistance of spinnerets and effects of drafting, etc., to achieve the effects of excellent antistatic properties, good bonding firmness, and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

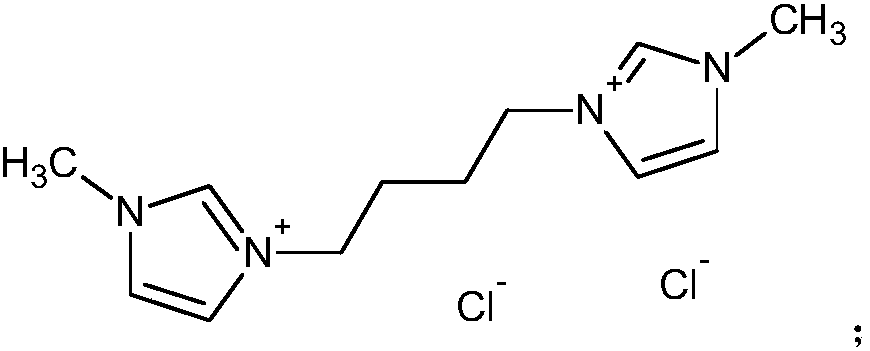

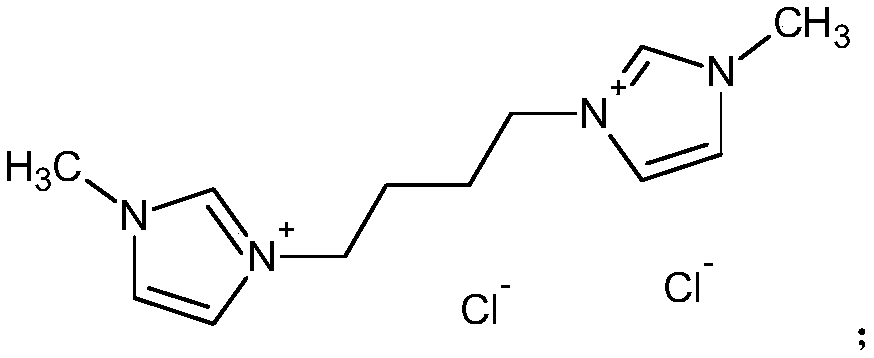

[0051] 1. Preparation of 1,4-bis[1-(3-methylimidazolium)]butyl dichloride:

[0052] Under nitrogen protection at 80°C, slowly drop 1.2mol N-methylimidazole into 1mol 1,4-dichlorobutane, after the dropwise addition, reflux for 72 hours to complete the reaction, and cool the reaction solution to room temperature to obtain The product was washed with ether to remove unreacted raw materials, and a white solid was obtained, which was bis-1,4-bis[1-(3-methylimidazole)]butyl dichloride (HPLC purity was 98.8%, yield 88 %).

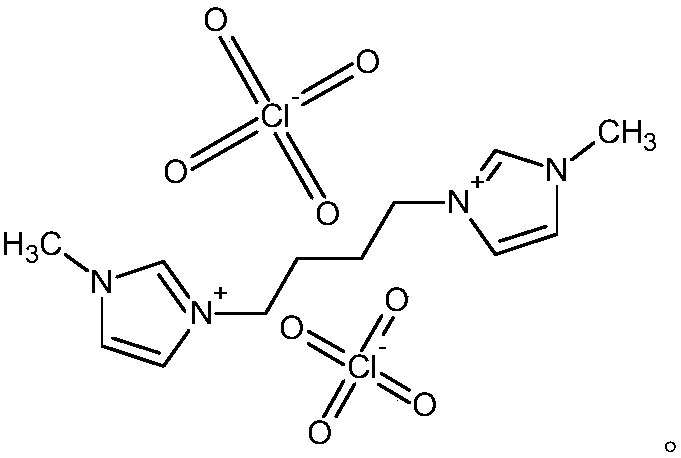

[0053] Two, the preparation of 1,4-bis[1-(3-methylimidazole)]butyl diperchlorate:

[0054] Dissolve 1 mol of 1,4-bis[1-(3-methylimidazolium)]butyl dichloride and 1.2 mol of lithium perchlorate in 1L of water, then stir and react at 80°C for 36 hours, then cool to room temperature, Stirring was continued at room temperature for 12 hours, the reaction solution was dispersed into an equal volume of chloroform, separated, the chloroform phase was washed with water u...

Embodiment 2

[0073] The difference between this embodiment and Example 1 is only: 0.5 mass parts of silicon oxide (particle diameter is about 100nm), 0.015 mass parts of graphene oxide and 9.485 mass parts of cotton pulp (cellulose content is 99%, polymerized degree is 600) after mixing evenly, add 100 parts by mass, 85wt% in the ionic liquid aqueous solution, and the remaining contents are all the same as described in Example 1.

[0074] After testing, the cellulose graphene composite short fiber prepared in this example has a breaking strength of about 3.6 cN / dtex when the single filament fineness is 1.5 dtex; 1-Butyl-3-methylimidazolium chloride, 1,4-bis[1-(3-methylimidazolium)]butyl dichloride or 1,4-bis[1-(3-methylimidazolium) )] When a single ionic liquid aqueous solution of butyl diperchlorate dissolves graphene oxide and cotton pulp, it needs to be stirred at 110-130°C for 3-5 hours to obtain a stable and uniform spinning solution, and the single-filament fineness In the case of t...

Embodiment 3

[0077] The difference between this embodiment and Example 1 is only: 0.5 mass parts of silicon oxide (particle diameter is about 100nm), 0.025 mass parts of graphene and 9.475 mass parts of cotton pulp (cellulose content is 99%, polymerization degree 600) after mixing evenly, add 100 parts by mass, 85 wt% of the ionic liquid aqueous solution, and the rest of the content is the same as that described in Example 1.

[0078] After testing, the cellulose graphene composite short fiber prepared in this example has a breaking strength of about 3.8 cN / dtex when the single filament fineness is 1.5 dtex; 1-Butyl-3-methylimidazolium chloride, 1,4-bis[1-(3-methylimidazolium)]butyl dichloride or 1,4-bis[1-(3-methylimidazolium) )] When a single ionic liquid aqueous solution of butyl diperchlorate dissolves cotton pulp, graphene and cotton pulp, it needs to be stirred at 110-130°C for 3-5 hours to obtain a stable and uniform spinning stock solution, and in When the monofilament fineness is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com