Method for preparing high-efficiency biomass fuel by using graphene

A biomass fuel and graphene technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of poor performance and not optimal performance, and achieve the effect of enhancing combustion effect, promoting stability and enhancing combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method utilizing graphene to prepare high-efficiency biomass fuel of the present embodiment comprises the following steps:

[0025] Step 1: Add 26 parts of modified graphene powder to 20 parts of tetrahydrofuran and 80 parts of absolute ethanol mixed solution for ultrasonic dispersion for 15 minutes, then add 34 parts of pretreatment base material and 6 parts of algae-dissolving microbial particles to it, and the stirring speed Raise to 75r / min, stir for 35min, then add 3 parts of oleic acid, 2 parts of rosin, and continue stirring for 15min to obtain a premix, wherein the preparation method of modified graphene powder is to mix potassium permanganate, high silicon ore Mix according to the weight ratio of 2:5, then add to the mixture of absolute ethanol and triethylamine according to the weight ratio of 75:25, heat until completely dissolved, then add graphene to it, and ultrasonically disperse in the ice-water bath for 35min, Then add ammonia wate...

Embodiment 2

[0033] A kind of preparation method utilizing graphene to prepare high-efficiency biomass fuel of the present embodiment comprises the following steps:

[0034] Step 1: Add 28 parts of modified graphene powder to 20 parts of tetrahydrofuran and 80 parts of absolute ethanol mixed solution for ultrasonic dispersion for 25 minutes, then add 38 parts of pretreatment base material and 12 parts of algae-dissolving microbial particles to it, and the stirring speed Raise to 85r / min, stir for 45min, then add 5 parts of oleic acid, 4 parts of rosin, and continue stirring for 25min to obtain the premix, wherein the preparation method of modified graphene powder is to mix potassium permanganate, high silicon ore Mix according to the weight ratio of 2:5, then add to the mixture of absolute ethanol and triethylamine according to the weight ratio of 75:25, heat until completely dissolved, then add graphene to it, and ultrasonically disperse in the ice-water bath for 35min, Then add ammonia w...

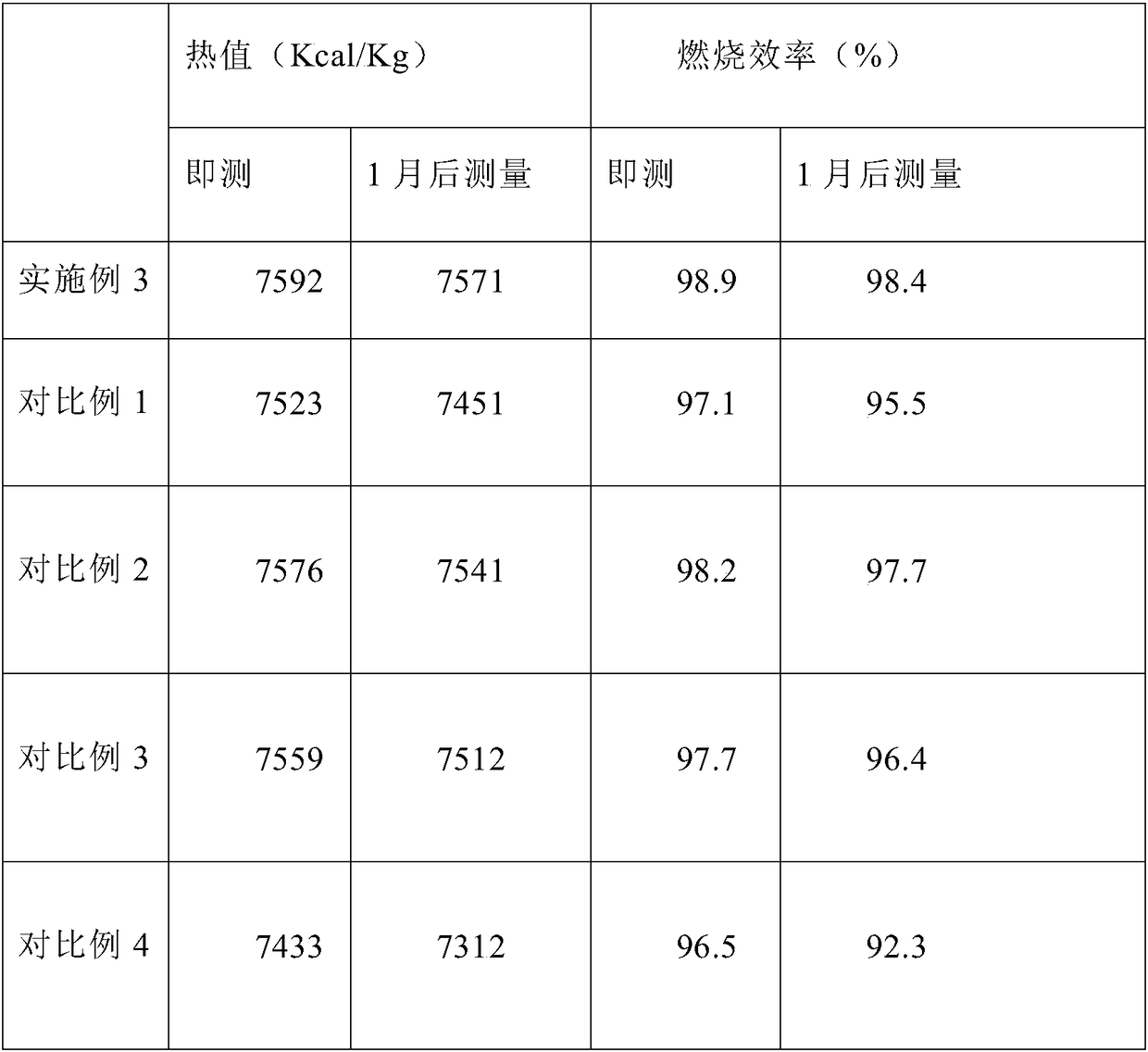

Embodiment 3

[0042] A kind of preparation method utilizing graphene to prepare high-efficiency biomass fuel of the present embodiment comprises the following steps:

[0043] Step 1: Add 27 parts of modified graphene powder to 20 parts of tetrahydrofuran and 80 parts of absolute ethanol mixed solution for ultrasonic dispersion for 20 minutes, then add 36 parts of pretreatment base material and 10 parts of algae-dissolving microbial particles to it, and the stirring speed Raise to 80r / min, stir for 40min, then add 4 parts of oleic acid, 3 parts of rosin, and continue to stir for 20min to obtain the premix, wherein the preparation method of modified graphene powder is to mix potassium permanganate, high silicon ore Mix according to the weight ratio of 2:5, then add to the mixture of absolute ethanol and triethylamine according to the weight ratio of 75:25, heat until completely dissolved, then add graphene to it, and ultrasonically disperse in the ice-water bath for 35min, Then add ammonia wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com