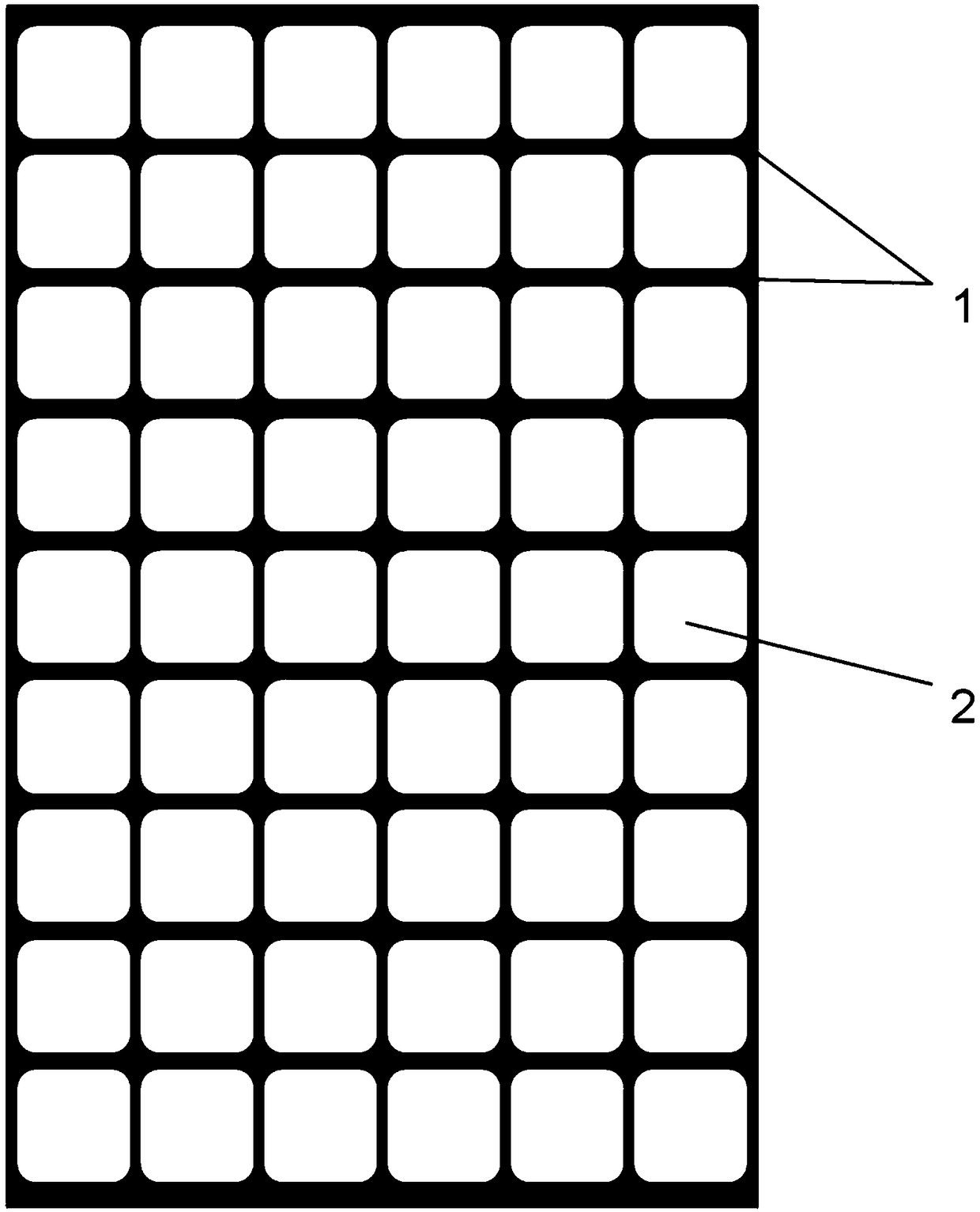

A power-enhanced transparent mesh backplane

A grid-based and enhanced technology, applied in the direction of photovoltaic power generation, electrical components, circuits, etc., can solve the problems of high cost and unfavorable weight, and achieve the effect of fast curing speed, small investment and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

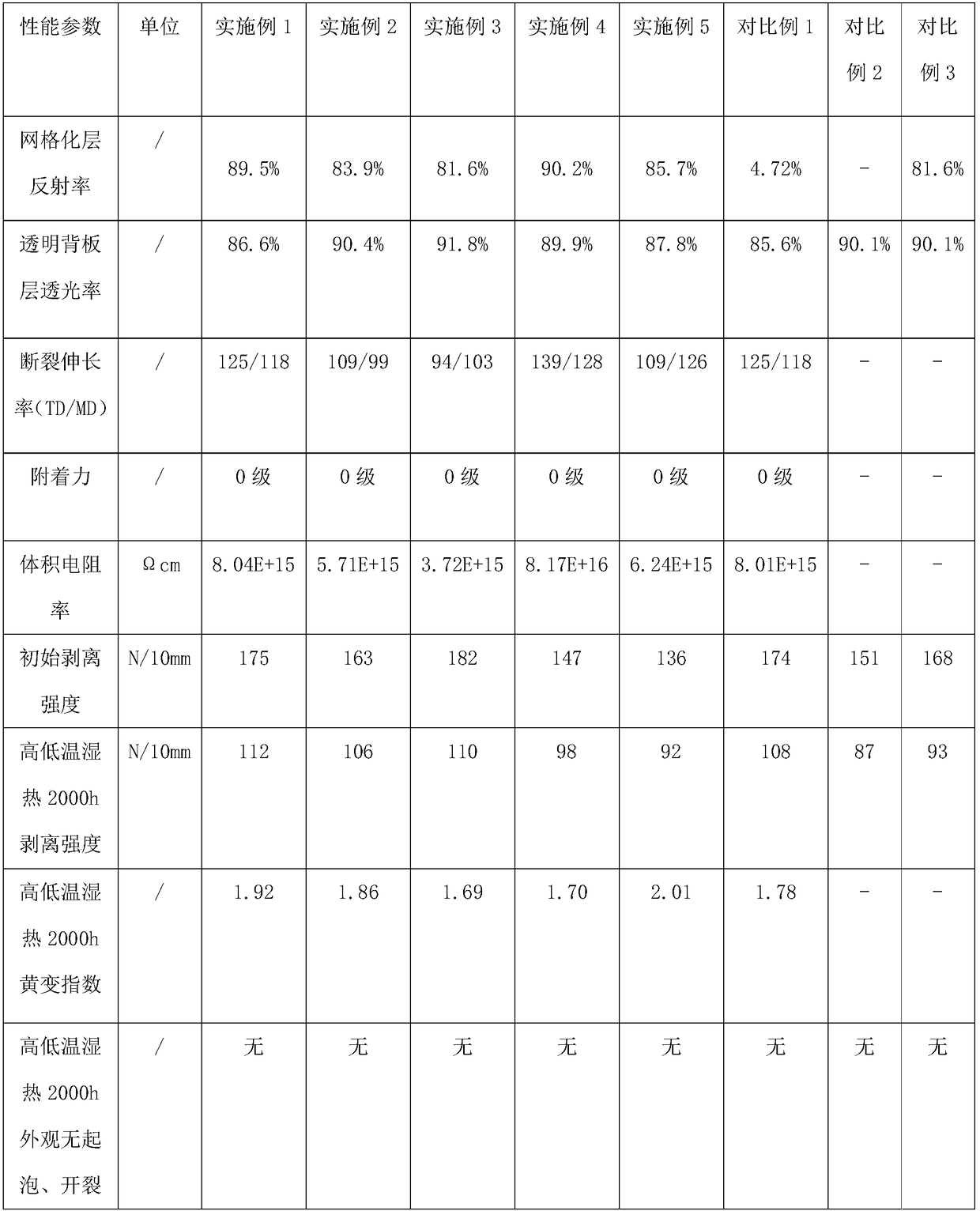

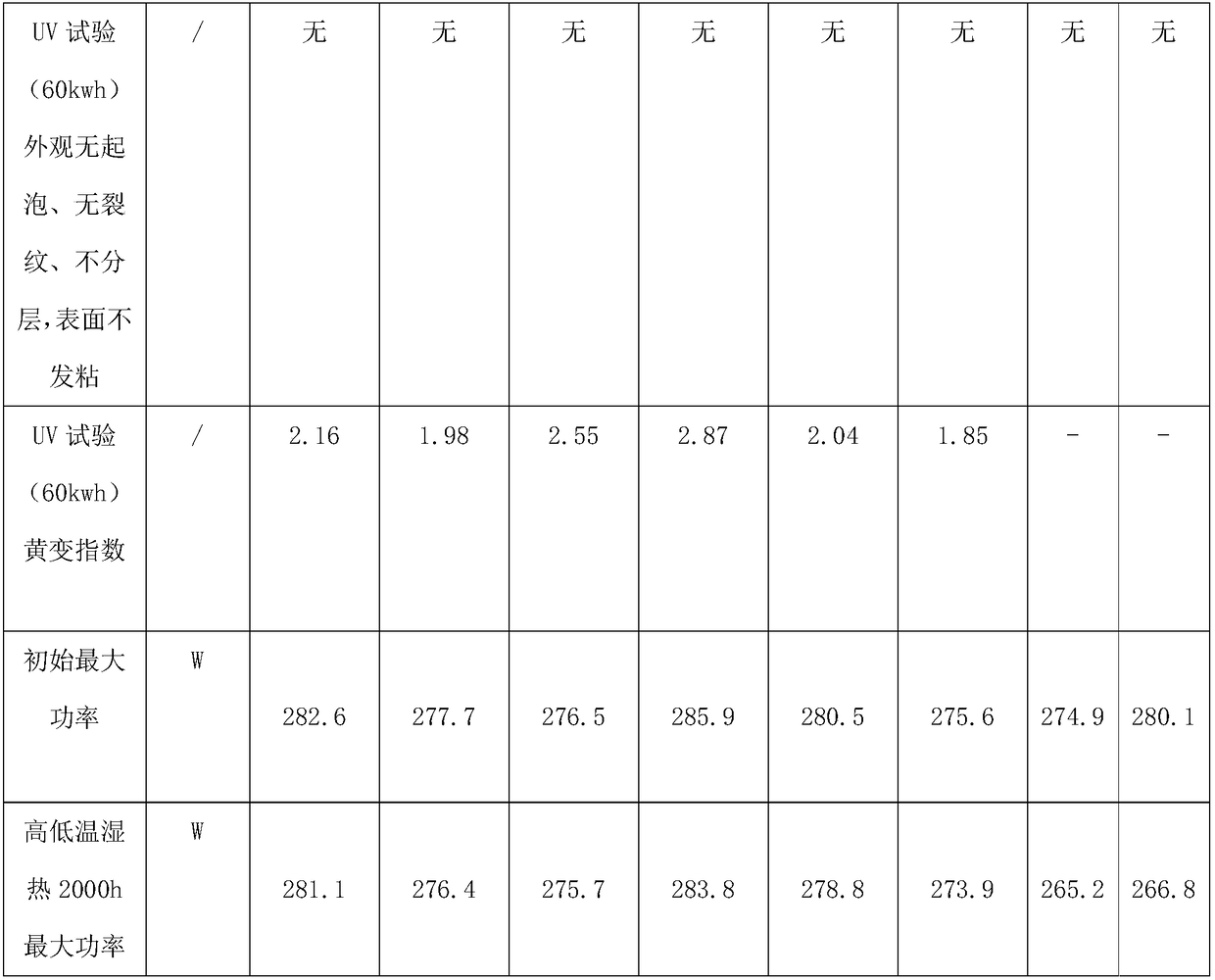

Embodiment 1

[0030] First, according to 40wt% bisphenol A epoxy acrylate, 10wt% 1,6-hexanediol diacrylate, 40wt% rutile titanium dioxide, 6wt% 4,4'-bis(dimethylamino) Benzophenone, 3wt% of the first auxiliary agent, 1wt% of the second auxiliary agent, etc. are mixed and configured to obtain a grid layer coating, wherein the first auxiliary agent is composed of 2-hydroxyl-4-n-octyloxydiphenyl The second auxiliary agent is composed of 50wt% polyether defoamer and 50wt% polyacrylate leveling agent.

[0031] Secondly, 40wt% of tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer, 1.6wt% of C5 petroleum resin, 0.2wt% of the third additive, 8wt% of nano-zinc oxide, 40wt% of ethyl acetate , 2wt% of the fourth additive, 8wt% of toluene diisocyanate trimer, 0.2wt% of organic tin catalyst, etc. are pre-mixed and configured into a transparent coating, and then coated on both sides of a 240um polyethylene naphthalate film The weather-resistant transparent coating with a thickness of 8um is dried ...

Embodiment 2

[0034] First, according to 50wt% novolac epoxy acrylate, 20wt% 1,6-hexanediol diacrylate and tripropylene glycol diacrylate in a 1:1 mixture, 25wt% rutile titanium dioxide and glass beads According to the composition of 1:2 mixed filler, 3wt% of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1.5wt% of the first additive, 0.5wt% of the second additive, etc. Configured to obtain a network layer coating, wherein the first additive consists of 50wt% 2‐hydroxy‐4‐octyloxybenzophenone and 50wt% bis(2,2,6,6‐tetramethyl‐4 ‐piperidinyl) sebacate, and the second auxiliary agent is composed of 50wt% polyacrylate leveling agent and 50wt% block copolymer dispersant containing pigment affinity groups.

[0035] Secondly, 45wt% of ethylene / trichlorofluoroethylene copolymer, 10wt% of butanol etherified urea-formaldehyde resin, 0.5wt% of the third additive, 5wt% of nano-titanium dioxide, 10wt% of xylene, 15wt% of the first Four additives, 14wt% of hexamethylene diisocyanate biuret and toluene ...

Embodiment 3

[0038] First, a mixture of 35 wt% polyurethane acrylate and unsaturated polyester resin in a ratio of 1:1, a mixture of 35 wt% trimethylolpropane triacrylate and a fluorine-containing acrylate monomer in a ratio of 1:2, 20wt% rutile titanium dioxide and glass microspheres are mixed fillers composed of 2:1, 6wt% 2-dimethylamino-2-benzyl-1-[4-(4-morpholinyl)phenyl]- 1-butanone, 3.99wt% of the first auxiliary agent, 0.01wt% of the second auxiliary agent and other mixed configurations to obtain a network layer coating, wherein the first auxiliary agent is composed of 40wt% 2-hydroxyl-4-n-octyloxy benzophenone, 30wt% bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate and 30wt% 2,6-di-tert-butyl-4-methyl Composed of phenol mixture, the second additive consists of 40wt% modified polysiloxane copolymer solution, 30wt% polyacrylate leveling agent and 30wt% block copolymer dispersant containing pigment affinity groups Mix composition.

[0039]Secondly, 30wt% of tetrafluoroethylene / perflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com