Reversible temperature-changeable water-based ink and its preparation method and application

A water-based ink, water-based technology, applied in the field of ink, can solve the problems of high discoloration temperature, non-compliance with environmental protection requirements, and heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing the above-mentioned reversible temperature-changing water-based ink. In a preferred embodiment, the specific steps are as follows:

[0032] (1) Mix the water-based binder, nano vanadium dioxide, non-toxic alcohol co-solvent, water and fillers, driers and / or water-based antioxidants added as needed to obtain a spare color paste;

[0033] (2) adjusting the pH of the spare color paste obtained in the step (1) by a pH regulator to be 8-9.5 to obtain a thermochromic water-based ink. Wherein, the pH regulator is selected from one or more of ethanolamine, ammonia water and triethylamine.

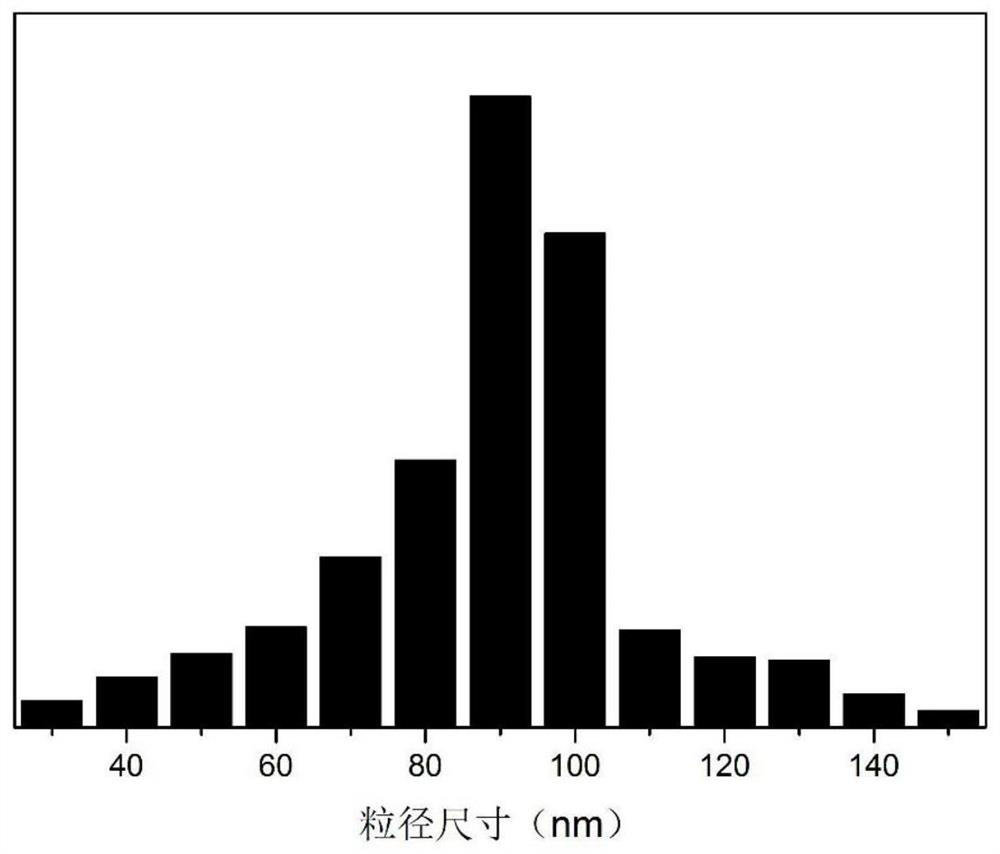

[0034] In a preferred embodiment of the present invention, the nano vanadium dioxide is prepared through the following steps:

[0035] Add vanadium pentoxide and oxalic acid dihydrate into water at a molar ratio of 1:1~3, heat and stir to form an aqueous solution, undergo a hydrothermal reaction at 180-250°C for 24-48 hours, cool to...

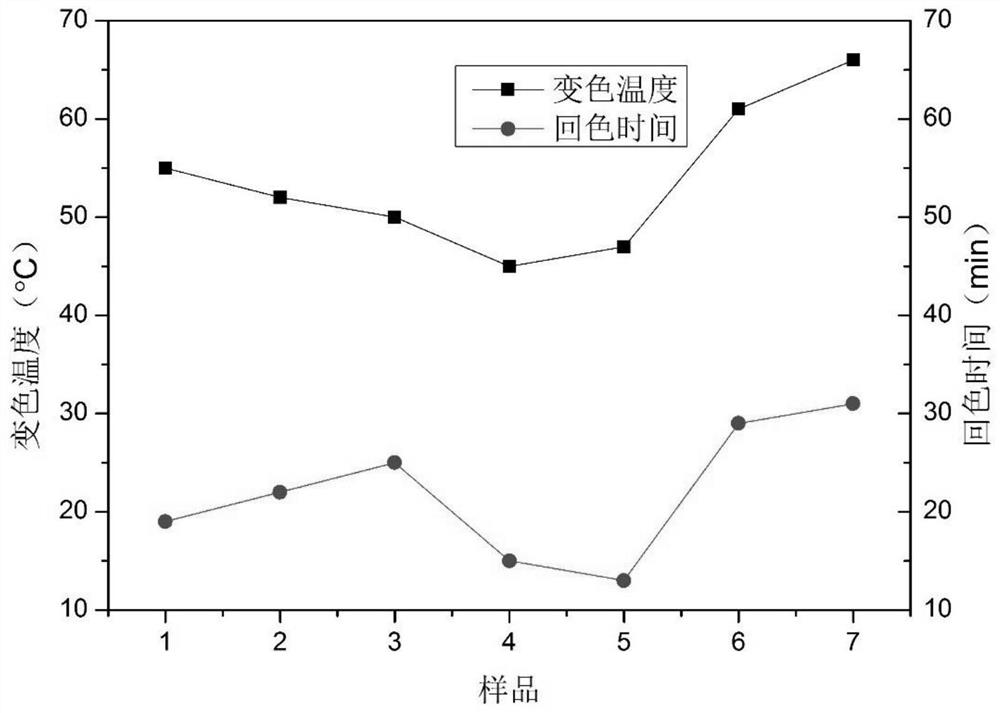

Embodiment 1

[0060] 1. Preparation of water-based polyurethane binder: Dry polypropylene glycol with a molecular weight of 2000 in vacuum at 110°C for 1.5h, mix and react with isophorone diisocyanate at 90°C for 1.5h, and then add the environmentally friendly organic bismuth catalyst DY -20 After continuing to accelerate the reaction for 1 hour, lower the temperature of the system to 60°C, add chain extender dimethylol propionic acid for chain extension reaction for 20 minutes, raise the temperature to the initial reaction temperature of 90°C, continue the reaction for 2 hours, then cool down to 50°C, add 1 , 4-butanediol and acetone adjust the viscosity of the system to 13mPa.s and continue to stir for 1 hour to obtain a water-based polyurethane prepolymer. Lower the temperature of the system to room temperature, add deionized water and a certain amount of ethanolamine, and adjust the pH value between 8.5 , Aging at room temperature for 12 hours, rotary evaporation to remove unreacted orga...

Embodiment 2

[0065] 1. Preparation of water-based polyurethane binder: same as Step 1 of Example 1.

[0066] 2. Preparation of nano-vanadium dioxide: add vanadium pentoxide and oxalic acid dihydrate to water at a feeding molar ratio of 1:1, heat and stir to form an aqueous solution, and cool to room temperature after hydrothermal reaction at 180°C for 48 hours, then separate The precipitate was washed with distilled water and ethanol, dried, and annealed at 800° C. for 2 hours under argon to obtain nano vanadium dioxide.

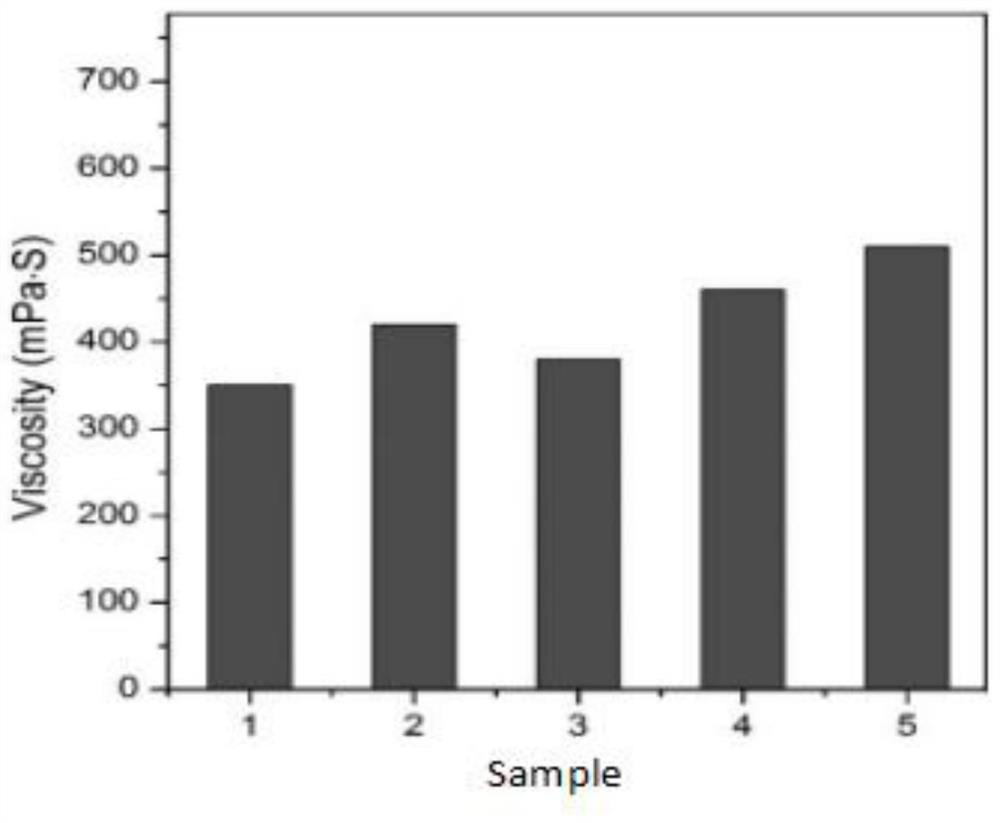

[0067] 3. Preparation of reversible temperature-changing water-based ink: 25 parts by weight of water-based polyurethane binder, 25 parts by weight of nano-vanadium dioxide, 5 parts by weight of non-toxic alcohol co-solvent, 25 parts by weight of water, nano-silica 25 parts by weight of powder, 0.5 parts by weight of drier and 3 parts by weight of antioxidant were uniformly mixed to obtain 30 g of spare color paste, and the pH of the spare color paste was adjusted to 8 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com