Production method of bilirubin adsorbent

A production method and technology of bilirubin, which are applied in the field of biomedicine, can solve the problems of high price and restrictions on the application of such products, and achieve the effects of good mechanical strength, safe and effective treatment, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, polyvinyl alcohol microspheres are the preparation of the adsorbent of carrier

[0032] a. Preparation of polyvinyl alcohol microspheres

[0033] Add 24g of vinyl acetate, 6g of triallyl isocyanurate, 15ml of ethyl acetate, 15ml of n-heptane and 1.6g of polyvinyl acetate (polymerization degree 500) into a 500ml three-necked flask, and the system is heated to 40°C. Mechanical stirring, add 0.3g initiator azobisisobutyronitrile after the polyvinyl acetate dissolves completely, add 300ml aqueous solution (by weight, containing 1.5% polyvinyl alcohol and 3% chlorine Sodium chloride), adjust the stirring speed to make the droplets uniformly dispersed and suitable in size, slowly raise the temperature to 65°C, keep the temperature and stirring speed for polymerization for 3 hours, then raise the temperature to 75°C for another 3 hours to obtain a white granular copolymer. Filter, wash with hot water, extract with acetone in a Soxhlet extractor for 12 hours, and...

Embodiment 4

[0038] Example 4. Fixation of 1,6-hexanediamine functional group: Take 1ml of the activated microspheres obtained in the step of Example 1b, add 0.75ml 2mol / L NaOH, 5ml 1,6-hexanediamine, shake overnight at 75°C , and then fully washed with distilled water to obtain a bilirubin adsorbent for future use.

Embodiment 5

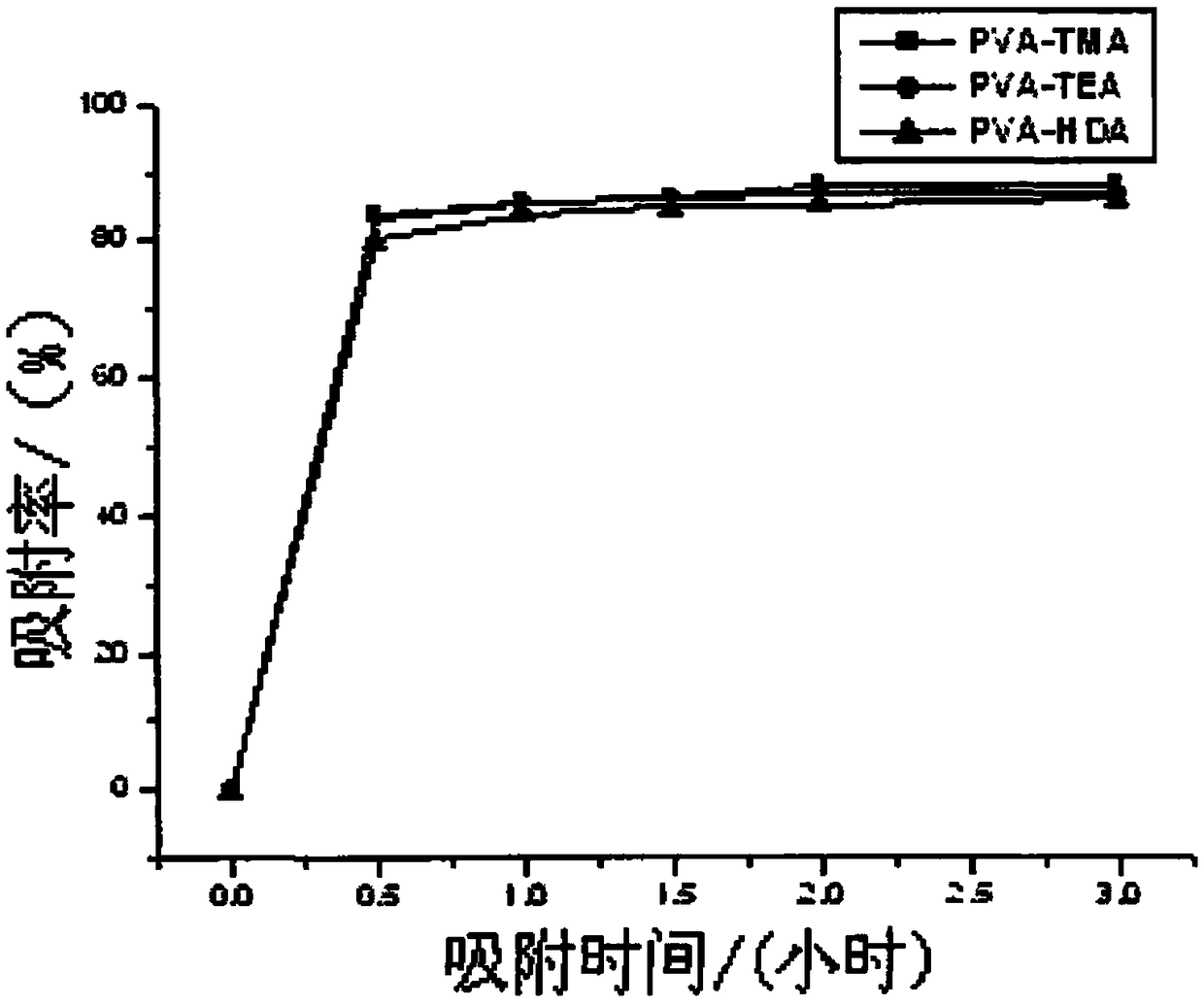

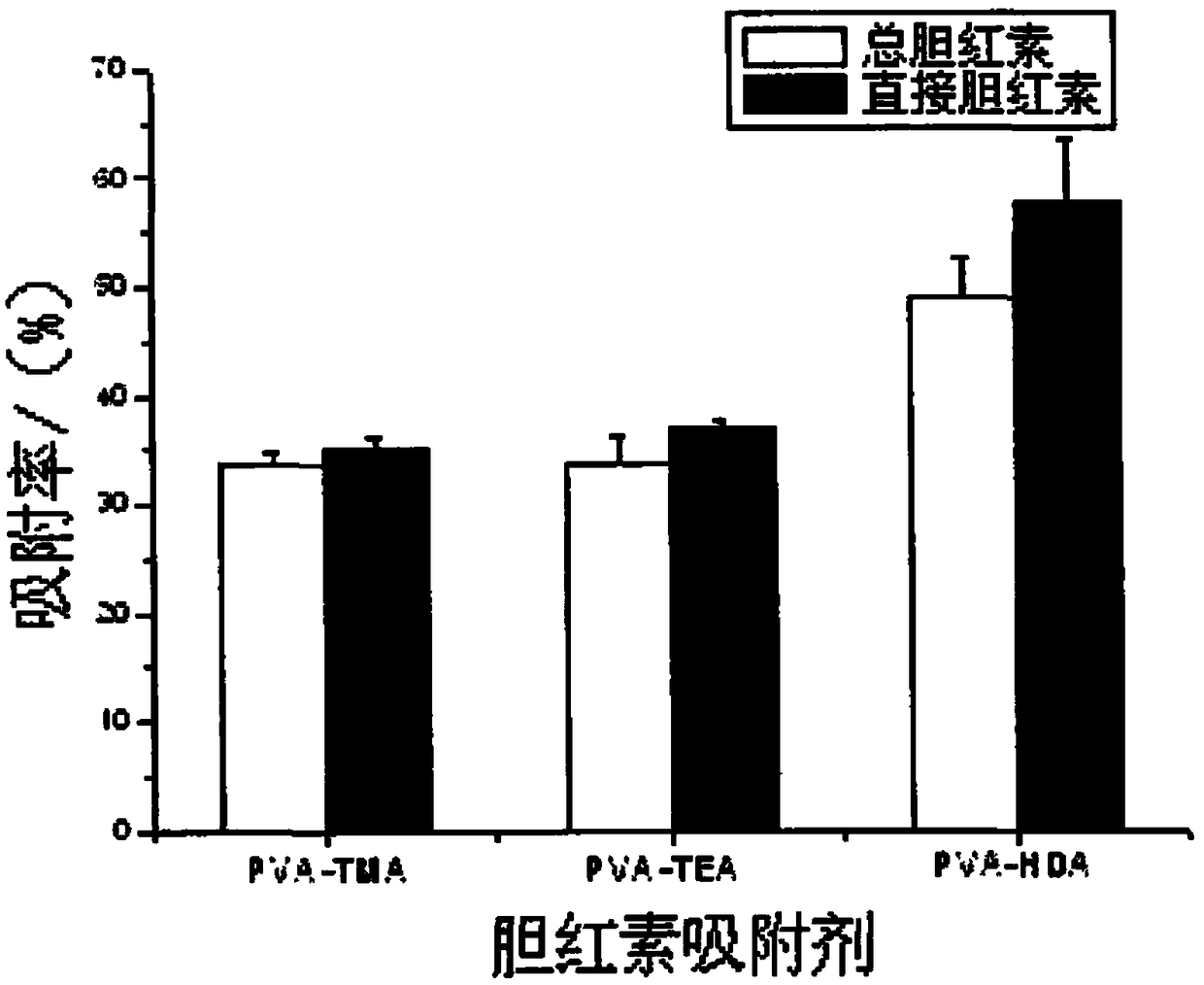

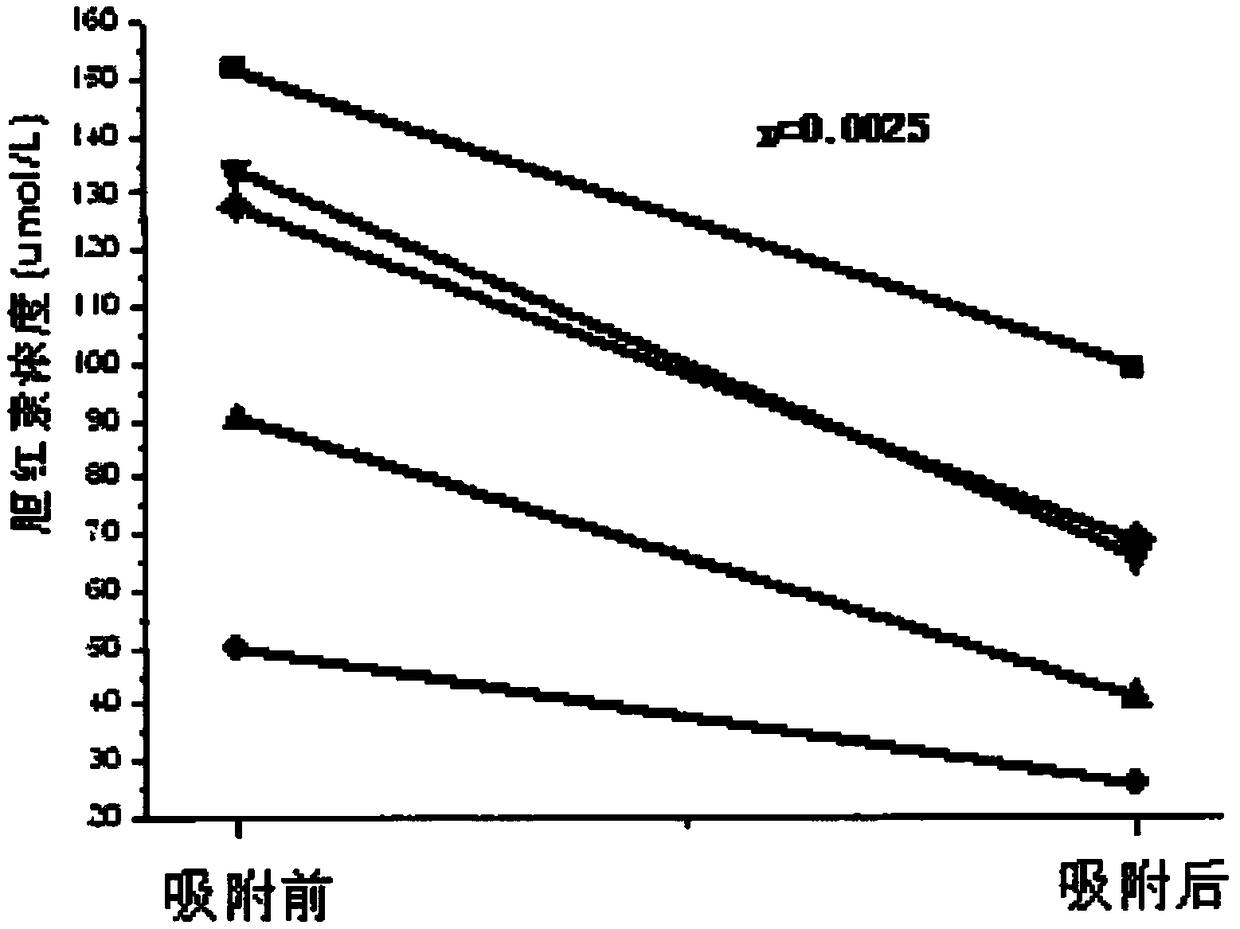

[0039] Embodiment 5, adsorbent in vitro static adsorption experiment: measure 0.5ml respectively by embodiment 2, embodiment 3, the adsorbent prepared in embodiment 4, place in the polypropylene plastic tube of 10.0ml, add appropriate amount of normal saline Equilibrate for 3 hours, absorb free physiological saline, add 5.0ml of bilirubin simulated serum solution with a concentration of 342μmol / L (a certain amount of bilirubin is dissolved in PBS buffer, which contains 20g / L albumin), 37°C Shake at constant temperature for 3 hours, let it stand for a while, absorb the supernatant to measure the concentration of bilirubin, and set a blank control, the adsorption rate is calculated by the following formula:

[0040] AP=([C]B-[C]A) / [C]B×100%

[0041] Where AP is the adsorption rate (%), [C]B and [C]A are the concentrations before and after adsorption (mg / dl).

[0042] By embodiment 2, embodiment 3, the adsorption rate of the adsorbent that embodiment 4 makes is respectively 93%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com