Antibacterial glass fiber reinforced polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of plastics, can solve the problems of easy aging and non-antibacterial materials, and achieve the effect of improving warpage, obvious antibacterial effect, anti-mildew effect, and shrinkage difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

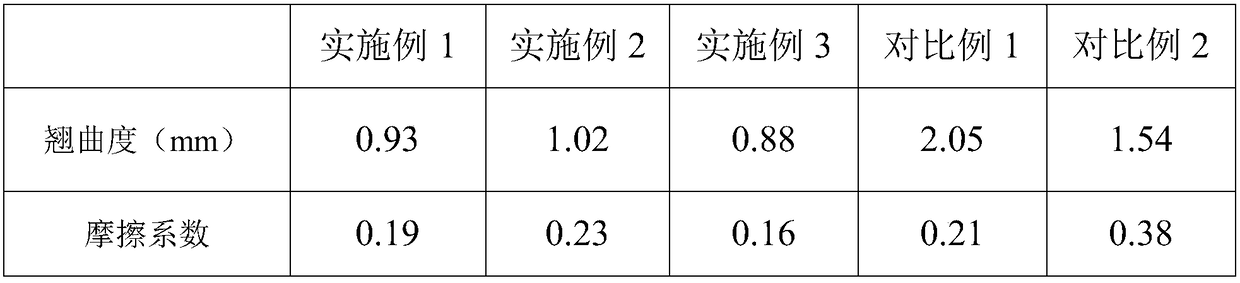

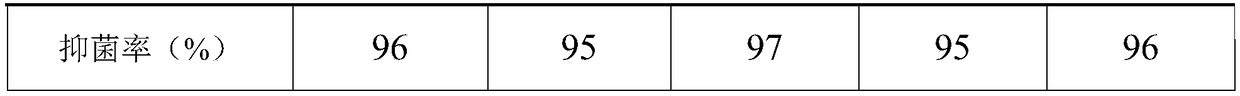

Examples

Embodiment 1

[0022] An antibacterial glass fiber reinforced polypropylene composite material, calculated in parts by weight, including the following components:

[0023] 61 parts of copolymerized polypropylene, 12 parts of long glass fiber, 25 parts of organic coated modified silicon carbide powder, 10 parts of tetrapod nano zinc oxide whiskers, 3 parts of dimethyl itaconate, 2 parts of antibacterial agent, isopropyl 2 parts of tris(dioctyl phosphate acyloxy) titanate, 9 parts of ethylene-octene copolymer, 0.9 parts of phenolic heat stabilizer, tetra[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionic acid]pentaerythritol ester 0.5 parts and zinc stearate 0.9 parts. Organically coated modified silicon carbide powder is obtained by first treating silicon carbide with a silane coupling agent and then grafting acrylamide onto the surface. The antibacterial agent is a mixture of cyclic polyformin hydrochloride and layered double hydroxide.

[0024] Preparation:

[0025] Copolymerized polypropylene, 36...

Embodiment 2

[0027] An antibacterial glass fiber reinforced polypropylene composite material, calculated in parts by weight, including the following components:

[0028] 55 parts of copolymerized polypropylene, 15 parts of long glass fiber, 20 parts of organic coated modified silicon carbide powder, 12 parts of tetrapod nano zinc oxide whiskers, 2 parts of dimethyl itaconate, 1.5 parts of antibacterial agent, isopropyl 1 part of tris(dioctyl phosphate acyloxy) titanate, 6 parts of ethylene-octene copolymer, 0.5 part of phenolic heat stabilizer, tris(2,4-di-tert-butylphenyl) phosphite 0.2 part of ester and 0.6 part of zinc stearate. Organically coated modified silicon carbide powder is obtained by first treating silicon carbide with a silane coupling agent and then grafting acrylamide onto the surface. The antibacterial agent is a mixture of cyclic polyformin hydrochloride and layered double hydroxide.

[0029] Preparation:

[0030] Copolymerized polypropylene, long glass fiber accounting for 3...

Embodiment 3

[0032] An antibacterial glass fiber reinforced polypropylene composite material, calculated in parts by weight, including the following components:

[0033] 65 parts of homopolypropylene, 10 parts of long glass fiber, 30 parts of organic coated modified silicon carbide powder, 8 parts of tetrapod nano zinc oxide whiskers, 4 parts of dimethyl itaconate, 3.5 parts of antibacterial agent, three parts 3 parts of isopropyl titanate isostearate, 12 parts of ethylene-propylene-diene copolymer, 1.2 parts of phosphite heat stabilizer, tetra[β-(3,5-di-tert-butyl-4-hydroxyl Phenyl) propionic acid] pentaerythritol ester 0.8 parts and polypropylene wax 1.8 parts. Organically coated modified silicon carbide powder is obtained by first treating silicon carbide with a silane coupling agent and then grafting acrylamide onto the surface. The antibacterial agent is a mixture of cyclic polyformin hydrochloride and layered double hydroxide.

[0034] Preparation:

[0035] The homopolypropylene, long gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com