Graphite phase carbon nitride foam composite cuprous oxide nanoparticle photocatalytic material and preparation method thereof

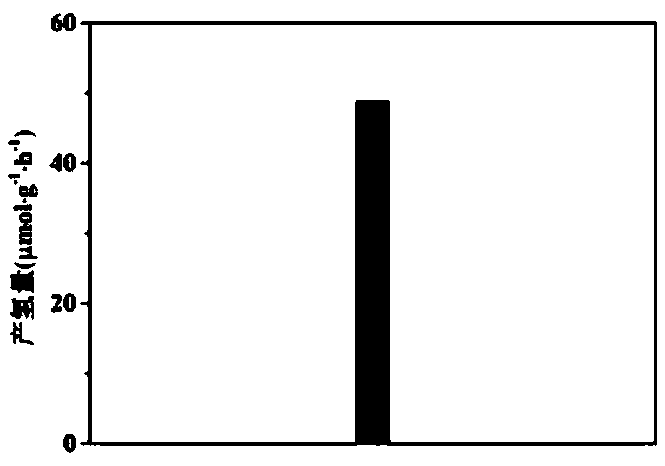

A technology of graphite phase carbon nitride and photocatalytic materials, applied in the field of photocatalytic materials, can solve the problems of poor composite effect and insufficient loading capacity, and achieve the effects of strong reduction ability, large loading capacity, and improved photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

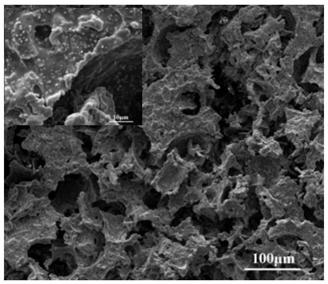

[0021] The graphite phase C 3 N 4 The preparation method of the foam is: first mix 5-14 parts by mass of graphite phase C 3 N 4 Added into 100 parts by mass of deionized water, mixed evenly to obtain a suspension; 1.7 to 2.0 parts by mass of sodium dodecylsulfonate, 1.7 to 2.0 parts by mass of dodecyl alcohol and 1.7 parts by mass were added to the suspension ~2.0 parts by mass of resin glue, stirred at 40~60°C and 100~200r / min for 10~20min to obtain a mixed solution; then the mixed solution was stirred for 15 ~20min, then add 5~14 parts by mass of binder to the mixed liquid under stirring, and continue stirring for 5~10min to obtain graphite phase C 3 N 4 foam slurry; finally the graphite phase C 3 N 4 The foam slurry is poured and molded, freeze-dried for 6-12 hours, and dried at 80-100°C for 18-24 hours to obtain graphite phase C 3 N 4 Foam.

[0022] The graphite phase C 3 N 4 The particle size is 1-20μm, graphite phase C 3 N 4 The main chemical components are:...

Embodiment 1

[0024] A graphite-phase carbon nitride foam composite cuprous oxide nano-particle photocatalytic material and a preparation method thereof. The preparation method described in this embodiment is:

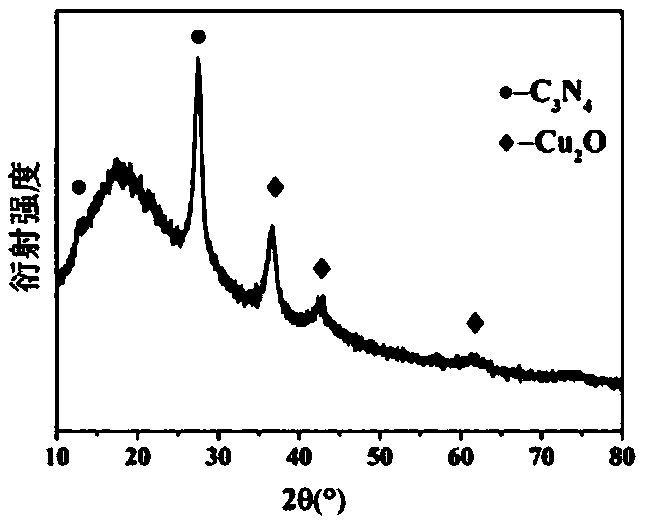

[0025] With a flow rate of 10-12 parts by mass / min, 5-6 parts by mass of CuSO 4 ·5H 2 O solution was added to 1 mass part of graphite phase C at a uniform speed 3 N 4 In the foam, let it stand for 3-4 minutes to obtain graphite phase C 3 N 4 Foam Composite CuSO 4 Block material; then add 3 to 4 parts by mass of NaOH solution to the graphite phase C at a constant speed at a flow rate of 3 to 4 parts by mass / minute 3 N 4 Foam Composite CuSO 4 In bulk materials, react at room temperature for 15-20 minutes to obtain graphite phase C 3 N 4 Foam composite Cu(OH) 2Block material; then add 10 to 20 parts by mass of glucose solution into the graphite phase C at a constant speed at a flow rate of 5 to 10 parts by mass / minute 3 N 4 Foam composite Cu(OH) 2 The bulk material is rea...

Embodiment 2

[0029] A graphite-phase carbon nitride foam composite cuprous oxide nano-particle photocatalytic material and a preparation method thereof. The preparation method described in this embodiment is:

[0030] With a flow rate of 12 to 14 parts by mass / min, 6 to 7 parts by mass of CuSO 4 ·5H 2 O solution was added to 1 mass part of graphite phase C at a uniform speed 3 N 4 In the foam, let it stand for 4-5 minutes to obtain graphite phase C 3 N 4 Foam Composite CuSO 4 Block material; then add 4 to 5 parts by mass of NaOH solution to the graphite phase C at a constant speed at a flow rate of 4 to 5 parts by mass / minute 3 N 4 Foam Composite CuSO 4 In bulk materials, react at room temperature for 20-25 minutes to obtain graphite phase C 3 N 4 Foam composite Cu(OH) 2 Block material; then add 15 to 25 parts by mass of glucose solution into the graphite phase C at a constant speed at a flow rate of 7.5 to 12.5 parts by mass / min 3 N 4 Foam composite Cu(OH) 2 The bulk materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com