Fluorescent microspheres with carboxyl group-enriched surface and synthesis method of fluorescent microspheres

A technology of fluorescent microspheres and synthesis methods, applied in the field of polymer materials and their synthesis, can solve the problems of uncontrollable particle size of microspheres, complex synthesis methods, high price and cost, and achieve low price, simple operation, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

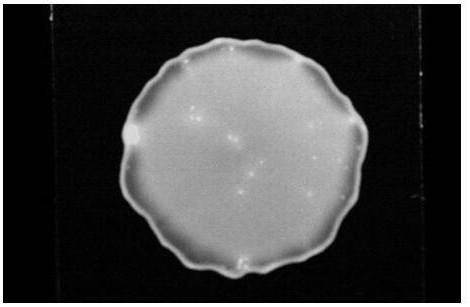

Image

Examples

Embodiment 1

[0029] 1) Preparation of carboxylated microspheres:

[0030] Place a four-necked round-bottomed flask equipped with an air guide tube, a reflux condenser, and a feeding port in an oil bath heater, start mechanical stirring with a polytetrafluoroethylene stirring rod, and keep the stirring speed at 400 rpm. Add distilled water, methanol, styrene, sodium p-styrene sulfonate and itaconic acid in sequence, seal the reaction system and feed nitrogen with stirring to remove the original oxygen in the system. After the temperature was raised to 70°C, potassium persulfate solution was added to the reaction mixture to start the reaction, the temperature was kept stirring for 24 hours, and then the reaction was stopped. The collected emulsion is the desired poly (St-co-IA) microspheres. Unreacted IA and other reagents were removed by high-speed centrifugation, and the resulting microspheres were redispersed in distilled water.

[0031] 2) Preparation of carboxylated fluorescent micros...

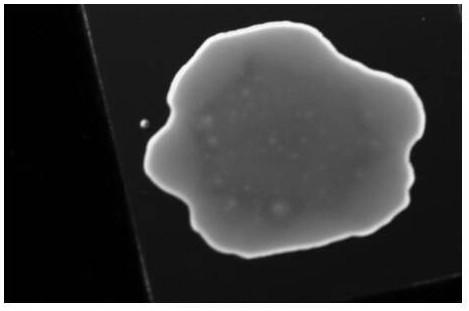

Embodiment 2

[0034] Example 2: 1) Preparation of carboxylated microspheres:

[0035] Place a four-necked round-bottomed flask equipped with an air guide tube, a reflux condenser, and a feeding port in an oil bath heater, start mechanical stirring with a polytetrafluoroethylene stirring rod, and keep the stirring speed at 400 rpm. Add distilled water, methanol, methacrylates, sodium p-styrenesulfonate and fumaric acid in sequence, close the reaction system and feed nitrogen gas while keeping stirring to remove the original oxygen in the system. After the temperature was raised to 60° C., potassium persulfate solution was added to the reaction mixture to start the reaction, the temperature was kept stirring for 30 hours, and then the reaction was stopped. The collected emulsion is the desired microspheres. Unreacted IA and other reagents were removed by high-speed centrifugation, and the resulting microspheres were redispersed in distilled water.

[0036] 2) Preparation of carboxylated flu...

Embodiment 3

[0040] 1) Preparation of carboxylated microspheres:

[0041]Place a four-necked round-bottomed flask equipped with an air guide tube, a reflux condenser, and a feeding port in an oil bath heater, start mechanical stirring with a polytetrafluoroethylene stirring rod, and keep the stirring speed at 400 rpm. Add distilled water, methanol, acrylic acid esters, sodium p-styrenesulfonate and fumaric acid in sequence, seal the reaction system and feed nitrogen gas while keeping stirring to remove the original oxygen in the system. After the temperature was raised to 70°C, the azobisisobutyronitrile solution was added to the reaction mixture to start the reaction, the temperature was kept stirring for 24 hours, and then the reaction was stopped. The collected emulsion is the desired microspheres. Unreacted IA and other reagents were removed by high-speed centrifugation, and the resulting microspheres were redispersed in distilled water.

[0042] 2) Preparation of carboxylated fluore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com