Compound material used for hexavalent chromium removal and preparation method thereof

A composite material and hexavalent chromium technology, which is applied in the field of magnetic biochar/iron tetrasulfide composite material and its preparation, can solve the problems of small specific surface area and single surface adsorption active center of ordinary iron-based materials, and achieves low cost, The effect of rich surface functional groups and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

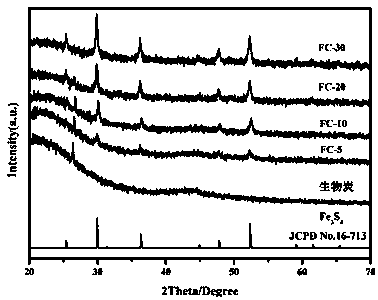

[0033] A magnetic biochar / ferric iron tetrasulfide composite material for hexavalent chromium removal, prepared by the following steps:

[0034] 1) Using rice husks as raw materials, thermally cracking them at 600°C for 2 hours under oxygen-limited conditions to obtain black biochar solids;

[0035] 2) The biochar obtained in 1) is pulverized by a pulverizer with a power of 1000W for 5 minutes, and the obtained powder is passed through a 100-mesh sieve;

[0036] 3) The biochar powder obtained in 2) is soaked and washed with 0.1mol / L hydrochloric acid to remove impurities such as ash and residue in the biochar;

[0037] 4) Put the biochar powder obtained in 3) in a blast drying oven, set the temperature at 90°C, and dry for 6 hours, and the obtained solid is clean biochar;

[0038] 5) Dissolve ferrous sulfate heptahydrate in 25mL of ethylene glycol;

[0039] 6) Thoroughly mix 1.0 g of biochar with the iron-containing solution in step 5) by ultrasonic;

[0040] 7) Dissolve L-...

Embodiment 2

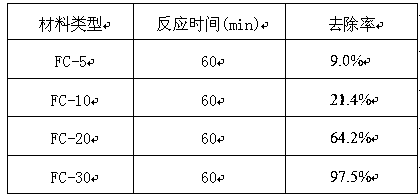

[0051] Four kinds of magnetic biochar / ferric iron tetrasulfide composite materials prepared in Example 1 are applied to the treatment of waste water containing hexavalent chromium ions, comprising the following steps:

[0052] 1) Weigh an appropriate amount of potassium dichromate and dissolve it in ultrapure water to make a 20mg / L hexavalent chromium ion stock solution;

[0053] 2) Take 50mL of the above hexavalent chromium stock solution in a 100mL conical flask, weigh 0.04g of FC-5, FC-10, FC-20, FC-30 composite materials in the solution, and immediately transfer to constant temperature shaking In the device, set the rotation speed to 200r / min and the temperature to 25°C;

[0054] 3) After reacting for 5, 10, 20, 30, 40, and 60 minutes respectively, take 1 mL of sample and 2 mL of diphenylcarbazide color developer to develop color, and measure the absorbance of the mixture with a UV-visible spectrophotometer;

[0055] The absorbance obtained after the reaction solution was c...

Embodiment 3

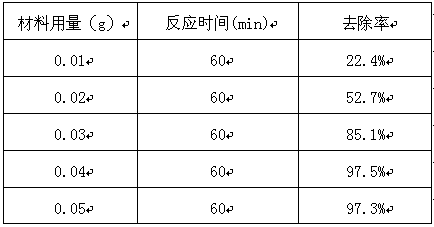

[0059] The magnetic biochar / ferric sulfide composite material prepared in Example 1 is applied to the treatment of waste water containing hexavalent chromium ions, comprising the following steps:

[0060] 1) Weigh an appropriate amount of potassium dichromate and dissolve it in ultrapure water to make a 20mg / L hexavalent chromium ion stock solution;

[0061] 2) Take 50mL of the above hexavalent chromium stock solution in a 100mL Erlenmeyer flask, weigh 0.01, 0.02, 0.03, 0.04, 0.05g of FC-30 composite material in the solution, and immediately transfer to a constant temperature oscillator, set the speed 200r / min, the temperature is 25℃;

[0062] 3) After reacting for 5, 10, 20, 30, 40, and 60 minutes respectively, take 1 mL of sample and 2 mL of diphenylcarbazide color developer to develop color, and measure the absorbance of the mixture with a UV-visible spectrophotometer;

[0063] The absorbance obtained after the reaction solution is colored after the above reaction is analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com