Multistage conversion process for inferior oil products

An oil and inferior technology, which is applied in the field of multi-stage conversion of inferior oil, can solve the problems of large amount of waste water, strict requirements on reaction atmosphere and catalyst, etc., and achieves the effect of improving conversion rate and liquefaction yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

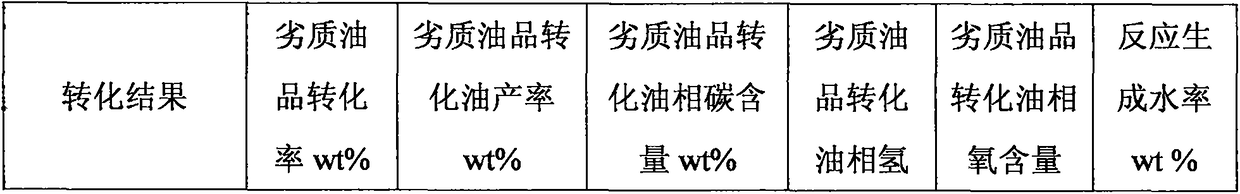

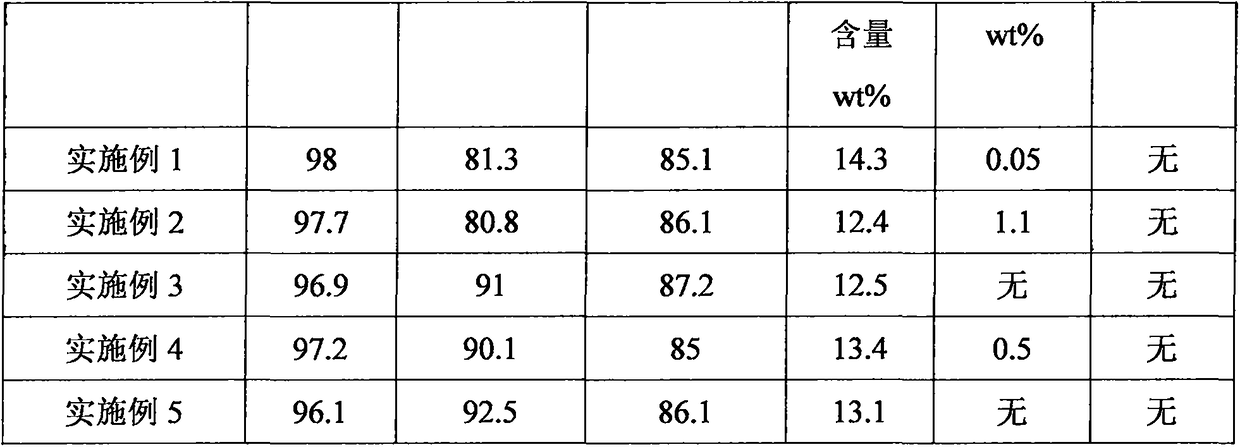

Examples

Embodiment 1

[0054] This embodiment provides a hogwash oil conversion process, comprising the following steps:

[0055] catalyst:

[0056] The catalyst is a waste agent of a desulfurizer with FeOOH as an active component, wherein, in the desulfurizer with FeOOH as an active component, the soluble iron salt Fe(NO 3 ) 3 9H 2 O is 6g, iron salt complexing agent triethanolamine 9g, amorphous iron oxyhydroxide 15g;

[0057] The above-mentioned desulfurizer with FeOOH as the active component is used to remove H in exhaust gas 2 The process of S is as follows: put H 2 S content is 5500mg / cm 3 exhaust gas at 3000h -1 The space velocity is passed into the desulfurization section, and the desulfurization reaction is carried out at 30°C. In the outlet gas of the desulfurization section, H 2 When the content of S is less than or equal to 0.01ppm, the waste in the desulfurization section is collected, which is the waste agent of the desulfurizer with FeOOH as the active component in this embodi...

Embodiment 2

[0067] The present embodiment provides a co-conversion process of wood tar and rancid oil, comprising the steps of:

[0068] catalyst:

[0069] The catalyst contains Fe 21.333 o 32 The regeneration of the waste agent of the desulfurization agent, wherein, the containing Fe 21.333 o 32 Among the desulfurizers, the magnetic iron oxide red Fe 21.333 o 32 55g, copper oxide 12g, carrier ferric oxide 21g;

[0070] The desulfurization process of the above-mentioned catalyst to coal pyrolysis gas containing hydrogen sulfide is as follows:

[0071] (1) The compressed coal pyrolysis gas is cooled to 30-35°C, mixed with the air from the air pump, and enters the desulfurization tower filled with the above-mentioned desulfurizer mainly with iron oxide as the active component, and adopts the process of bottom-in and top-out to avoid liquid water entering the desulfurizer bed to remove hydrogen sulfide;

[0072] (2) The above-mentioned desulfurizer becomes a waste agent after being ...

Embodiment 3

[0085] This embodiment provides an oil sand oil conversion process, comprising the following steps:

[0086] catalyst:

[0087] The catalyst is a waste agent of a desulfurizer with iron oxide as an active component, wherein, in the desulfurizer with iron oxide as an active component, calcium bicarbonate is 10g, basic copper carbonate is 12g, γ-Fe 2 o 3 18g, MnO 2 is 8g, NiO is 5g;

[0088] The desulfurization process of the above-mentioned desulfurizer with iron oxide as the active component is summarized as follows:

[0089] 1) Collect the tail gas produced by the fixed bed hydrogenation catalysis of medium and low temperature coal tar;

[0090] 2) The desulfurizing agent of this embodiment is made into columnar catalyst particles with a diameter of 1 mm and a length of 15 mm, and filled in the desulfurization tower to form a desulfurization layer;

[0091] 3) The above-mentioned tail gas is used for 2000h -1 The space velocity passes through the desulfurization layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com