Wastewater autotrophic denitrification nitrogen removal device and wastewater treatment method

An autotrophic denitrification and denitrification technology, which is applied in the field of wastewater autotrophic denitrification and denitrification devices, can solve the problems of low utilization rate and mass transfer rate of reducing sulfide, low reactor processing capacity, and incomplete denitrification treatment, etc. , to achieve the effect of facilitating microbial film formation, preventing device blockage, and improving corrosion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

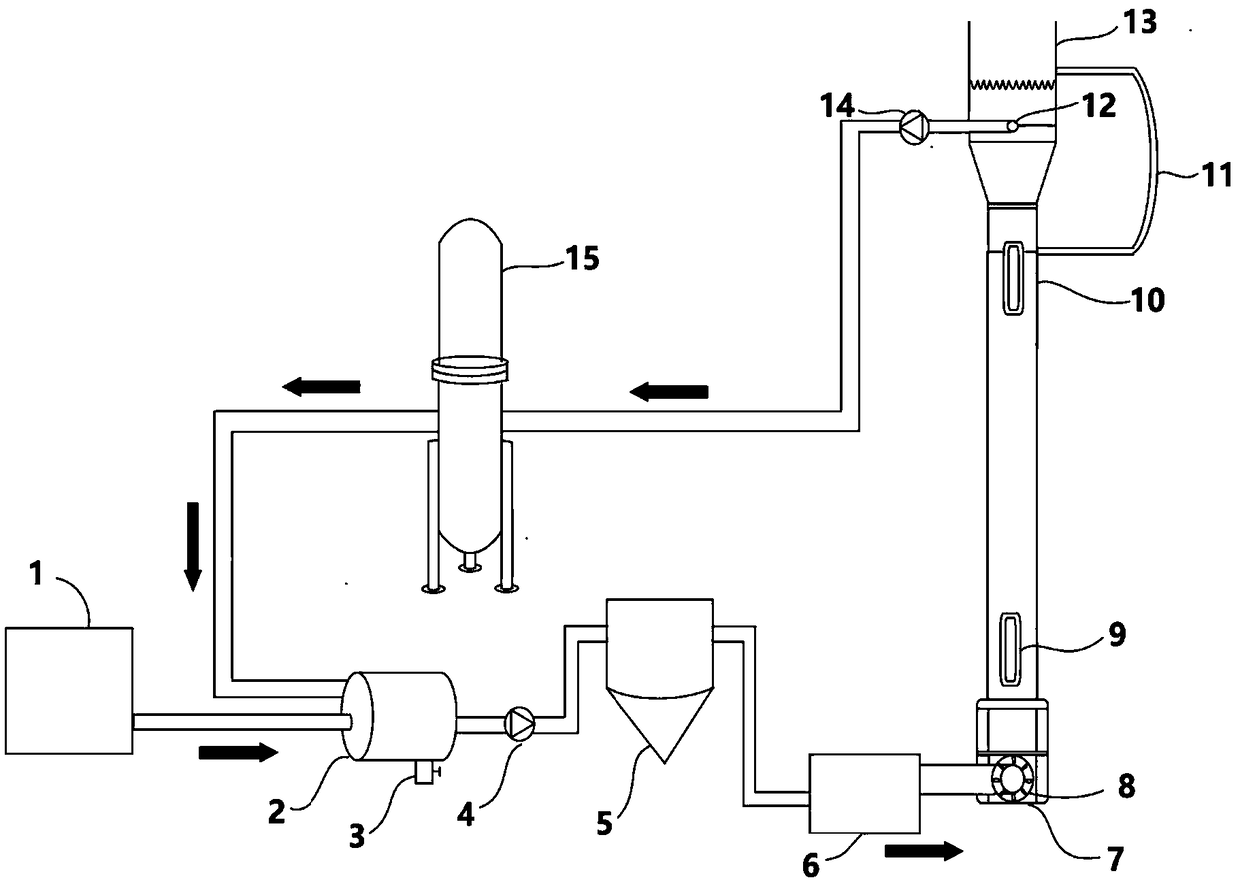

[0034] Such as figure 1 As shown, the device mainly includes a pre-settlement filter system, an internal circulating fluidized sulfur sand bed and a radial flow settler 14. 0.5mm) microporous screen microfiltration machine 2, peristaltic pump 4, conical sedimentation concentration tank 5 and supernatant liquid pool 6 at the bottom. Connect to the flow settler 15, the water outlet of the microfilter 2 is connected to the sedimentation concentration tank 5 through a pipeline, the upper outlet of the sedimentation concentration tank 5 is connected to the supernatant pool 6, and the supernatant pool 6 is connected to the internal circulating fluidized sulfur sand bed The bottom water inlet is connected, and the connecting pipe between the microfilter 2 and the sedimentation concentration tank 5 is provided with a peristaltic pump 4, and the microfilter 2 is also provided with a total water outlet 3;

[0035] The internal circulating fluidized sulfur sand bed includes a cylinder b...

Embodiment 2

[0047] In this embodiment, the device is further optimized on the basis of Embodiment 1. The drum of the microfilter 2 is provided with micropores with an aperture ranging from 0.9 to 1.0 mm (the aperture in this embodiment is 1.0 mm). Screens for separating solid waste from aquaculture wastewater.

[0048] The particle size range of the internal circulating fluidized sulfur sand bed cylinder is 0.45-0.82mm sulfur particles, the height of the fixed bed is 1.0m, and the width of the water inlet slit of the annular water inlet chamber 8 can be set within a range of 6-9mm In this embodiment, the width of 8mm is preferably set. After the waste water enters the annular water inlet chamber 8, a strong rotating water flow is generated, and then enters the cylinder 10 through the water inlet slit, and a strongly rotating upward water flow is generated under the action of the reflecting bottom plate 7. The water flow It drives the sulfur particles to rotate and float up, so that the sa...

Embodiment 3

[0059]This embodiment is further optimized on the basis of Embodiment 1. The drum of the microfilter is provided with a microporous screen with an aperture ranging from 1.1 to 1.2 mm (the aperture in this embodiment is 1.2 mm). , for the separation of solid waste in aquaculture wastewater.

[0060] The width range of the water inlet slit of the annular water inlet cavity of the internal circulating fluidized sulfur sand bed is 8 to 10mm, and the width of 10mm is preferably set in this embodiment. After the waste water enters the annular water inlet cavity, a strong rotating water flow is generated. Then it enters the cylinder through the water inlet slit, and under the action of the reflecting bottom plate, a strong rotating upward water flow is generated. The water flow drives the gravel to rotate and float up, making the sand bed expand, and finally flows out from the upper outlet.

[0061] The manufacturing material of the internal circulation fluidized sulfur sand bed is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com