Manufacturing method of moisturizing mask liquid

A production method and wet surface technology, which are applied in the directions of pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of poor whitening effect, unstable storage, poor effect, etc., so as to improve hydrophilicity, prevent Oxidation and cell regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

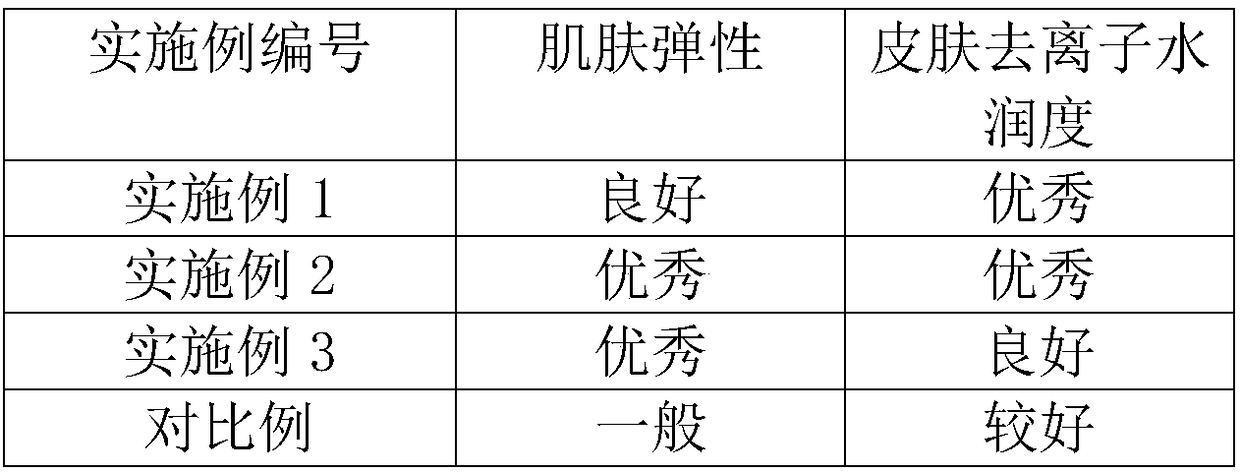

Examples

Embodiment 1

[0028] A method for making a water-replenishing and moisturizing facial mask liquid, comprising the steps of:

[0029] S1. Weigh by parts by weight: 90 parts of deionized water, 5.3 parts of glycerin, 2.8 parts of betaine, 0.15 parts of sodium hyaluronate, 0.05 parts of xanthan gum, 0.02 parts of polyethylene glycol-14M, hydroxyethyl cellulose Mix 0.005 parts of plain ingredients and 0.025 parts of thickener to make component A liquid;

[0030] S2. Weigh by parts by weight: 95 parts of deionized water, 10.02 parts of oligopeptide, 0.83 part of nicotinamide, 30.22 parts of ceramide, 0.1 part of hydrogenated lecithin, 0.011 part of cholesterol, and 0.004 part of octyldodecanol , 0.08 parts of herbal plant extracts, 0.38 parts of phenoxyethanol, 0.5 parts of ethylhexylglycerin, 0.5 parts of hesperidin methylchalcone, 0.5 parts of stearyl ether-200.3 parts, dipeptide-20.5 parts, palmitoyl tetra 70.5 parts of peptide, 1.5 parts of propylene glycol, 0.007 parts of citric acid, 0.08...

Embodiment 2

[0048] A method for making a water-replenishing and moisturizing facial mask liquid, comprising the steps of:

[0049] S1. Weigh by parts by weight: 100 parts of deionized water, 5 parts of glycerin, 1.9 parts of betaine, 0.18 parts of sodium hyaluronate, 0.04 parts of xanthan gum, 0.013 parts of polyethylene glycol-14M, hydroxyethyl cellulose Mix 0.01 part of vegetable and 0.03 part of thickener to make A component liquid;

[0050]S2. Weigh by parts by weight: 90 parts of deionized water, 10.03 parts of oligopeptide, 0.8 part of nicotinamide, 30.21 parts of ceramide, 0.15 part of hydrogenated lecithin, 0.01 part of cholesterol, and 0.003 part of octyldodecanol , 0.12 parts of herbal extracts, 0.35 parts of phenoxyethanol, 0.38 parts of ethylhexylglycerin, 1.0 parts of hesperidin methylchalcone, 200.1 parts of stearyl ether, 20.42 parts of dipeptide, palmitoyl tetra 0.7 parts of peptide-7, 1 part of propylene glycol, 0.005 parts of citric acid, 0.11 parts of arginine, 0.01 pa...

Embodiment 3

[0068] A method for making a water-replenishing and moisturizing facial mask liquid, comprising the steps of:

[0069] S1. Weigh by parts by weight: 95 parts of deionized water, 5.5 parts of glycerin, 1.5 parts of betaine, 0.17 parts of sodium hyaluronate, 0.06 parts of xanthan gum, 0.01 parts of polyethylene glycol-14M, hydroxyethyl cellulose Mix 0.008 parts of plain ingredients and 0.03 parts of thickener to make component A liquid;

[0070] S2. Weigh by parts by weight: 85 parts of deionized water, 10.027 parts of oligopeptide, 0.9 part of nicotinamide, 30.2 parts of ceramide, 0.13 part of hydrogenated lecithin, 0.012 part of cholesterol, and 0.002 part of octyldodecanol , 0.09 parts of herbal extracts, 0.42 parts of phenoxyethanol, 0.3 parts of ethylhexylglycerin, 0.8 parts of hesperidin methyl chalcone, 200.5 parts of stearyl ether, 20.2 parts of dipeptide, palmitoyl tetra 0.6 parts of peptide-7, 2 parts of propylene glycol, 0.003 parts of citric acid, 0.09 parts of argi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com