Polyurethane emulsion used for self-dry water-based nail polish, preparation method of polyurethane emulsion and nail polish prepared from polyurethane emulsion as base material

A polyurethane emulsion and nail polish technology, applied in manicure, cosmetic preparations, pedicure, etc., can solve the problems of easy precipitation, chapped, difficult to greatly improve performance, etc., and achieve excellent mechanical and chemical resistance. , strong adhesion and durability, good thermal storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A self-drying polyurethane emulsion for water-based nail polish, 600 parts of soybean oil, 100 parts of tartaric acid (2,3-dihydroxysuccinic acid), Al 3+ 60 parts of supported cation exchange resin, 400 parts of butanol, 500 parts of 30wt% hydrogen peroxide, 250 parts of isocyanate trimer, 100 parts of 1,4-butanediol, 50 parts of 2,2-dimethylol propionic acid , 30 parts of N-methylpyrrolidone, 3 parts of DBTDL, 20 parts of triethylamine, and 80 parts of deionized water.

[0054] Specifically, the preparation method of the above-mentioned polyurethane emulsion for self-drying water-based nail polish is as follows:

[0055] (1) Preparation of soybean oil polyol

[0056] Add soybean oil, tartaric acid, Al 3+ Loaded cation exchange resin catalyst, butanol and deionized water are heated up to 35°C and stirred evenly; then slowly add 30wt% hydrogen peroxide aqueous solution dropwise at 120mL / min at a stirring speed of 1300rpm, and control the dropping rate so that the react...

Embodiment 2

[0062] A self-drying polyurethane emulsion for water-based nail polish, 750 parts of soybean oil, 125 parts of tartaric acid, Al 3+ 75 parts of supported cation exchange resin, 450 parts of butanol, 650 parts of 30wt% hydrogen peroxide, 200 parts of isocyanate trimer, 120 parts of 1,4-butanediol, 75 parts of 2,2-dimethylol propionic acid , 50 parts of N-methylpyrrolidone, 4 parts of DBTDL, 30 parts of triethylamine, and 100 parts of deionized water.

[0063] Specifically, the above-mentioned polyurethane emulsion preparation method for water-based nail polish is as follows:

[0064] (1) Preparation of soybean oil polyol

[0065] Add soybean oil, tartaric acid, Al 3+ Loaded cation exchange resin catalyst, butanol and deionized water are heated up to 35°C and stirred evenly; then slowly add 30wt% hydrogen peroxide aqueous solution dropwise at 120mL / min at a stirring speed of 1300rpm, and control the dropping rate so that the reaction temperature is maintained at 40°C, after t...

Embodiment 3

[0070] Polyurethane emulsion for self-drying water-based nail polish is prepared from the following raw materials in parts by weight: 500 parts of soybean oil, 85 parts of tartaric acid, Al 3+ 65 parts of supported cation exchange resin, 350 parts of butanol, 500 parts of 30wt% hydrogen peroxide, 200 parts of isocyanate trimer, 110 parts of 1,4-butanediol, 60 parts of 2,2-dimethylol propionic acid , 25 parts of N-methylpyrrolidone, 4 parts of DBTDL, 15 parts of triethylamine, and 90 parts of deionized water.

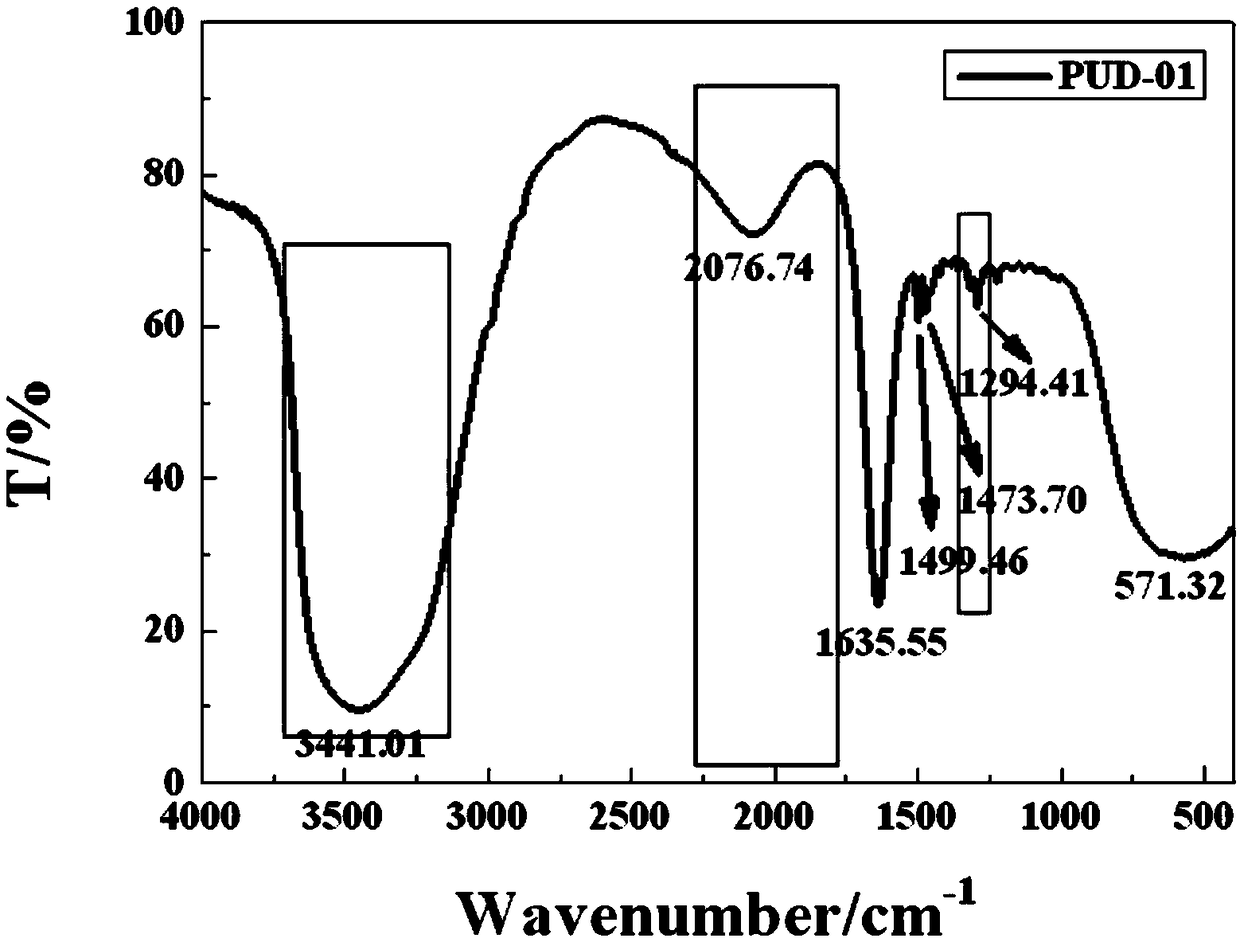

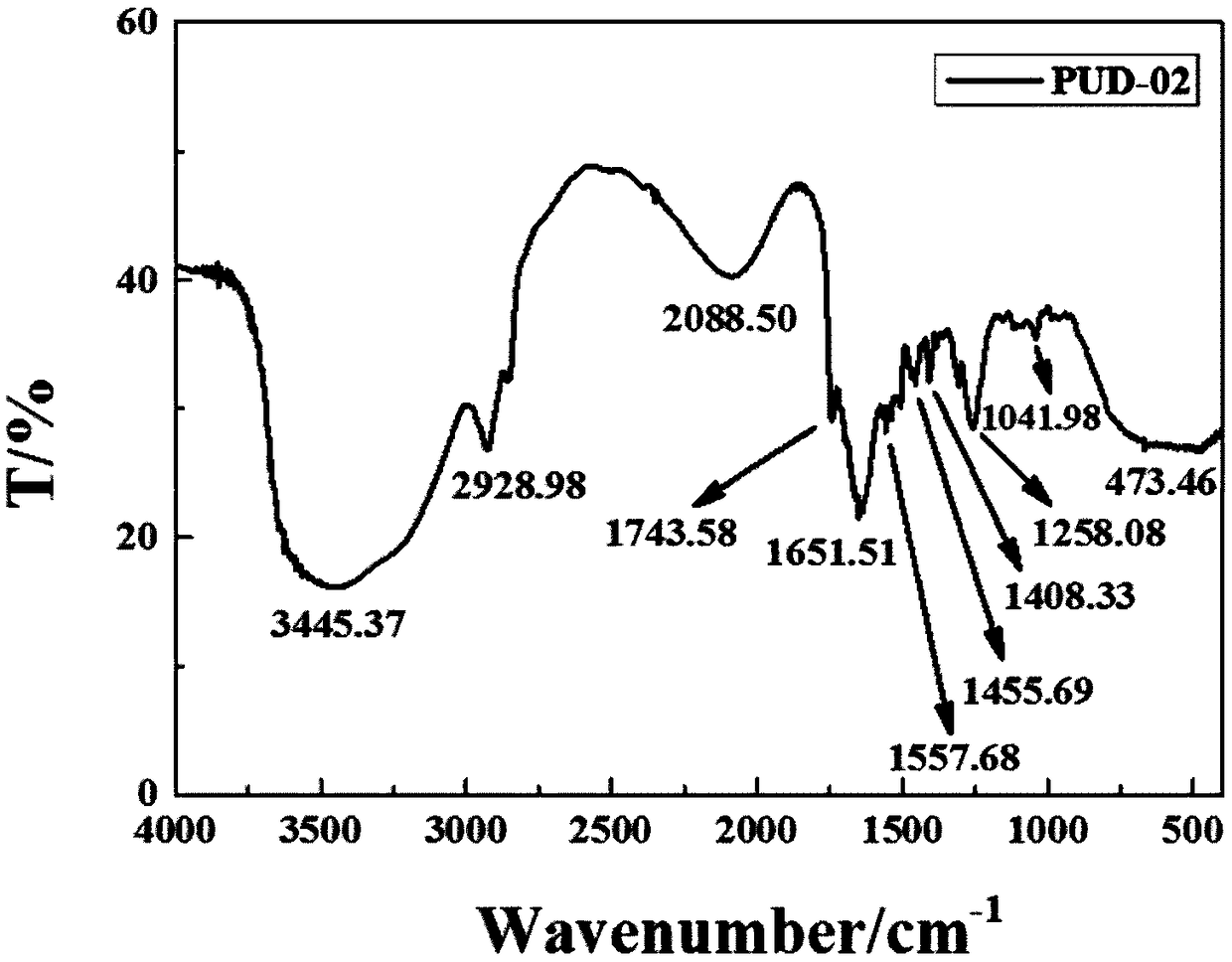

[0071] The preparation method is as in Example 1. The polyurethane emulsion for water-based nail polish prepared in Example 3 is analyzed by Fourier transform infrared spectrometer Nicolet 6700. The results are basically consistent with those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com