Layered double hydroxide composite electrode material and preparation method and application thereof

A technology of hydroxide and composite electrodes, applied in the direction of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc., can solve the limitations of practical applications, short cycle life, and low conductivity and other problems, to achieve the effect of more effective active sites, high specific capacitance, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

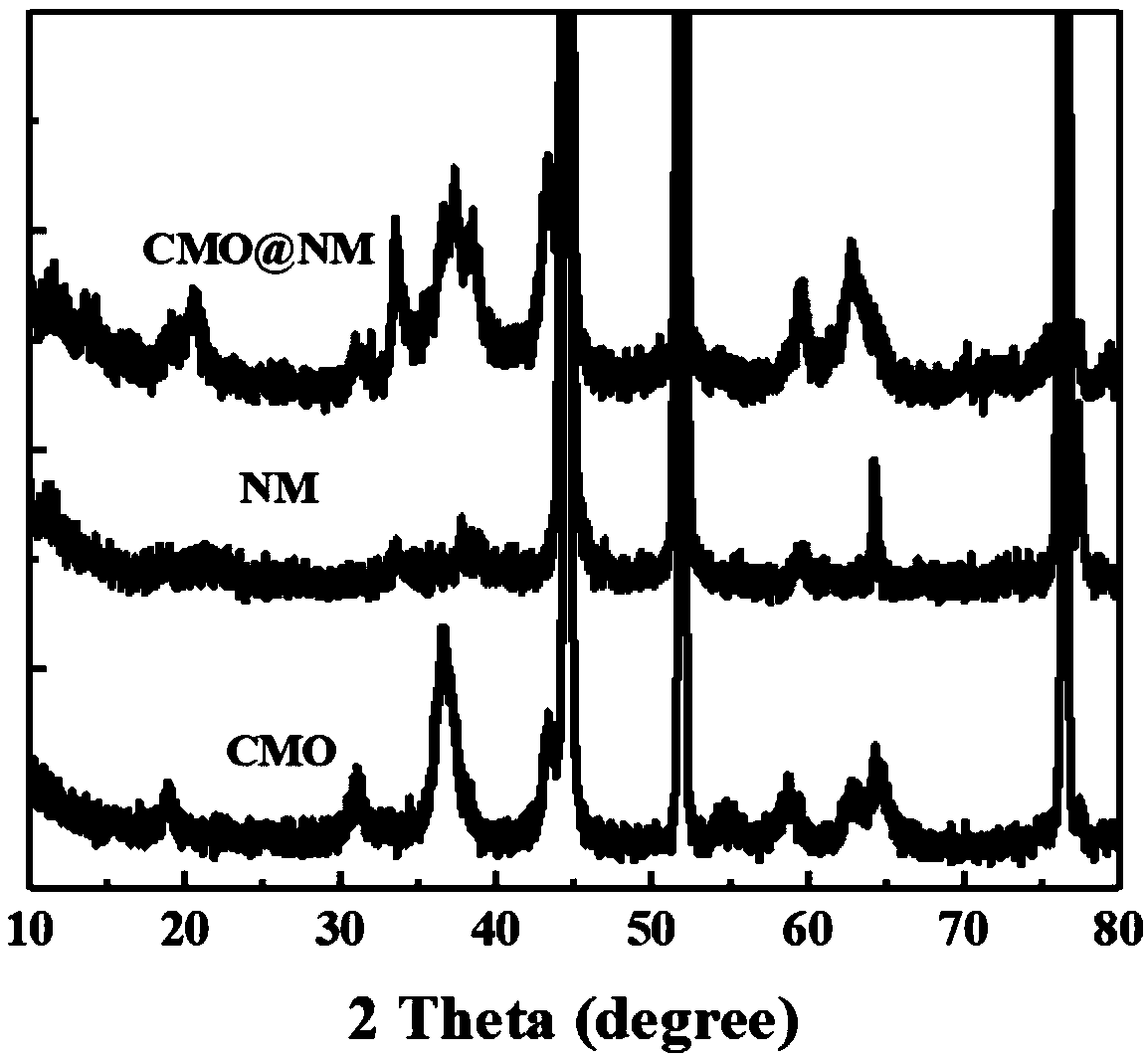

[0038] A preparation of a nickel-foamed cobalt manganate / nickel-manganese layered double hydroxide composite electrode material and research on its properties, comprising the following steps:

[0039] (1) Dissolve cobalt nitrate hexahydrate, manganese chloride tetrahydrate, ammonium fluoride and urea in 40 mL of deionized water, the mass of cobalt salt in the solution is 0.218g, the mass of manganese salt is 0.296g, and the mass of ammonium fluoride is 0.218g. Be 0.036g, the quality of urea is 0.72, stir and dissolve to obtain dispersion liquid 1;

[0040] (2) The dispersion liquid 1 configured in step (1) is transferred to the reactor, and the nickel foam (8 cm 2), hydrothermally reacted at 140 °C for 4 h. The resulting CoMn on nickel foam 2 O 4 The precursors were washed three times with deionized water and ethanol, respectively, and dried under vacuum at 60 °C for 5 h;

[0041] (3) the CoMn based on the nickel foam of step (2) gained 2 O 4 The precursor is heat-treate...

Embodiment 2

[0047] A preparation of a nickel-foamed cobalt manganate / nickel-manganese layered double hydroxide composite electrode material and research on its properties, comprising the following steps:

[0048] The preparation method of the cobalt manganate / nickel-manganese layered double hydroxide composite electrode material with nickel foam as the base is basically the same as that in Example 1, the difference is that the NiCl in step 4 of Example 1 is used. 2 ·6H 2 The mass of O was changed to 0.476 g, and other conditions remained unchanged. The material is named Ni 2 Mn 1 -LDH-CoMn 2 O 4 -NF.

Embodiment 3

[0050] A preparation of a nickel-foamed cobalt manganate / nickel-manganese layered double hydroxide composite electrode material and research on its properties, comprising the following steps:

[0051] The preparation method of the cobalt manganate / nickel-manganese layered double hydroxide composite electrode material with nickel foam as the base is basically the same as that in Example 1, the difference is that the NiCl in step 4 of Example 1 is used. 2 ·6H 2 The mass of O was changed to 0.714 g, and other conditions remained unchanged. The material is named Ni 3 Mn1-LDH-CoMn 2 O 4 -NF.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com