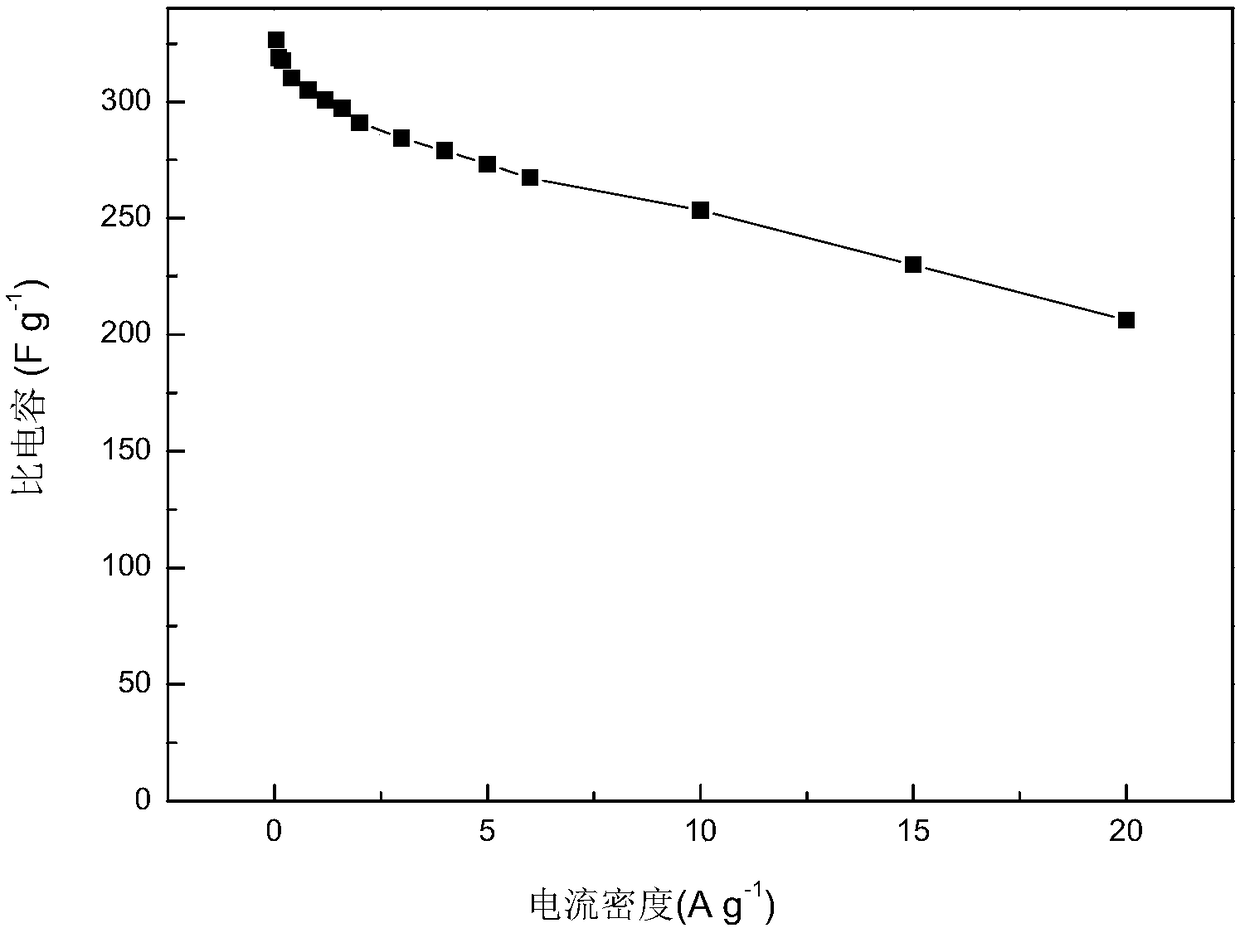

Preparation method of sulfur and nitrogen co-doped thin nanocarbon sheet for supercapacitor electrode

A technology of supercapacitors and carbon nanosheets, applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, chemical instruments and methods, etc., can solve problems such as unfavorable commercial applications, poor conductivity, and environmental pollution, and achieve Enrich the electrochemical active sites, enhance the activation effect, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Pretreatment of cigarette butts: the cigarette butts are cleaned with deionized water to remove surface impurities, dried after washing, and then pulverized to obtain cigarette butt fibers.

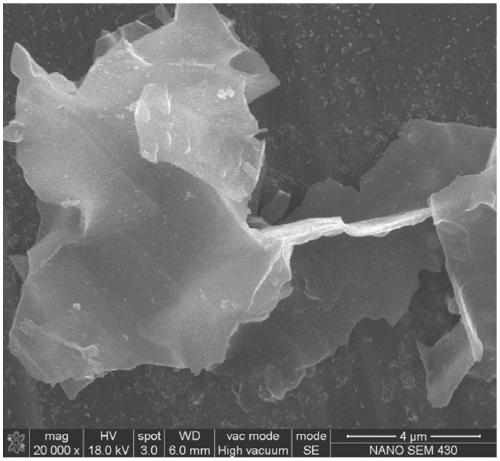

[0031] (2) Preparation of sulfur and nitrogen co-doped thin nano-carbon sheets: Weigh 3 g of cigarette butt fibers obtained in step (1) and dissolve them in 150 ml of distilled water, then add 3.6 g of potassium hydroxide, 2.4 g of sodium hydroxide, and 3 g of thiourea and mix evenly Then put it in a rotary evaporator, stir at 80°C for 2.5 hours at a speed of 90r / min, evaporate to dryness, then transfer to a tube furnace, and raise the temperature to 800°C at a rate of 5°C / min under an Ar atmosphere. Incubate for 2 hours to obtain the activated product.

[0032] (3) Pickle the activated product obtained in step (2) with 2mol / L hydrochloric acid, then wash it with deionized water until pH = 7, place the washed porous carbon in a drying oven, and dry at a constant temperature of ...

Embodiment 2

[0034] (1) Pretreatment of cigarette butts: the cigarette butts are cleaned with deionized water to remove surface impurities, dried after washing, and then pulverized to obtain cigarette butt fibers.

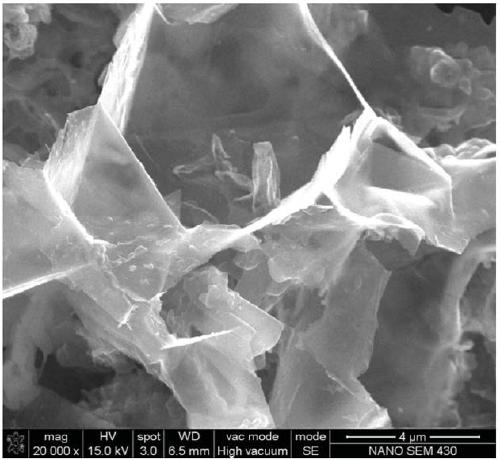

[0035] (2) Preparation of sulfur and nitrogen co-doped thin nano-carbon sheets: Weigh 3 g of cigarette butt fibers obtained in step (1) and dissolve them in 150 ml of distilled water, then add 3.6 g of potassium hydroxide, 2.4 g of sodium hydroxide, and 6 g of thiourea and mix evenly Then put it in a rotary evaporator, stir at 80°C for 2.5 hours at a speed of 90r / min, evaporate to dryness, then transfer to a tube furnace, and raise the temperature to 700°C at a rate of 5°C / min under an Ar atmosphere. Incubate for 2 hours to obtain the activated product.

[0036] (3) Pickle the activated product obtained in step (2) with 2mol / L hydrochloric acid, then wash it with deionized water until pH = 7, place the washed porous carbon in a drying oven, and dry at a constant temperature of ...

Embodiment 3

[0038] (1) Pretreatment of cigarette butts: the cigarette butts are cleaned with deionized water to remove surface impurities, dried after washing, and then pulverized to obtain cigarette butt fibers.

[0039] (2) Preparation of sulfur and nitrogen co-doped thin nano-carbon sheets: Weigh 3 g of cigarette butt fibers obtained in step (1) and dissolve them in 150 ml of distilled water, then add 1.8 g of potassium hydroxide, 1.2 g of sodium hydroxide, and 3 g of thiourea and mix evenly Then put it in a rotary evaporator, stir at 80°C for 2.5 hours at a speed of 90r / min, evaporate to dryness, then transfer to a tube furnace, and raise the temperature to 600°C at a rate of 5°C / min under an Ar atmosphere. Incubate for 2 hours to obtain the activated product.

[0040] (3) Pickle the activated product obtained in step (2) with 2mol / L hydrochloric acid, then wash it with deionized water until pH = 7, place the washed porous carbon in a drying oven, and dry at a constant temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com