A high-efficiency flame-retardant and antibacterial functional masterbatch for direct injection molding of polypropylene and its preparation method

A technology of injection molding and functional masterbatch, which is applied in the field of high-efficiency flame-retardant and antibacterial functional masterbatch and its preparation. Problems such as damage, interference with modification effect, etc., to ensure flame retardant and antibacterial modification effects, reduce the probability of mutual contact, and solve the effect of mutual loss of modification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

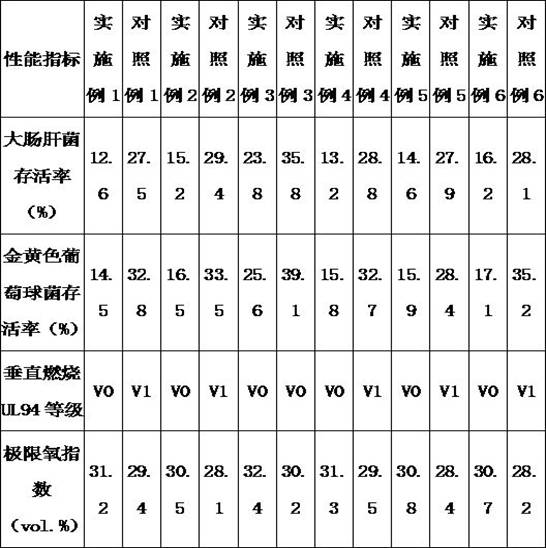

Examples

Embodiment 1

[0029] A high-efficiency flame-retardant and antibacterial functional masterbatch for polypropylene direct injection molding, which is composed of two masterbatches, A and B, and the mass ratio of raw materials for the A masterbatch is as follows:

[0030] Silver loaded zinc zeolite antimicrobial agent 10.0kg Barium sulfate 40.0 kg Glass fiber powder 30.0 kg Sodium ion crosslinked ethylene–acrylic acid copolymer elastic ionomer 18.0 kg stearic acid 1.0 g Ethylene bis stearamide 1.0 g

[0031] The mass ratio of the raw materials of the B masterbatch is as follows:

[0032] Octabromo-S ether 70.0 kg Antimony trioxide 15.0 kg Atactic polypropylene 13.0kg PTFE powder 1.0 kg stearic acid 500.0 g Ethylene bis stearamide 500.0 g

[0033] The preparation method of A masterbatch is as follows: Weigh all raw materials according to the above mass ratio requirements, put them into a high-speed...

Embodiment 2

[0036] A high-efficiency flame-retardant and antibacterial functional masterbatch for polypropylene direct injection molding, which is composed of two masterbatches, A and B, and the mass ratio of raw materials for the A masterbatch is as follows:

[0037] Silver-loaded zinc porous glass antibacterial agent 7.0 kg Barium sulfate 40.0 kg talcum powder 23.0 kg Zinc ion crosslinked ethylene–acrylic acid copolymer elastic ionomer 28.0 kg Oleamide 1.5 kg polyethylene wax 500.0 g

[0038] The mass ratio of the raw materials of the B masterbatch is as follows:

[0039] Decabromodiphenylethane 50.0 kg Octabromoether 10.0kg Antimony trioxide 16.5 kg Zinc borate 7.0 kg Atactic polypropylene 14.0kg PTFE powder 1.5 kg Oleamide 500.0 g polyethylene wax 500.0 g

[0040] The preparation method of A masterbatch is as follows: Weigh all raw materials according to the above mass rati...

Embodiment 3

[0043] A high-efficiency flame-retardant and antibacterial functional masterbatch for polypropylene direct injection molding, which is composed of two masterbatches, A and B, and the mass ratio of raw materials for the A masterbatch is as follows:

[0044] Silver-loaded zinc porous zirconium phosphate antibacterial agent 6.0 kg Barium sulfate 40.0 kg calcium carbonate 14.0kg Calcium ion crosslinked ethylene–acrylic acid copolymer elastic ionomer 38.0kg Zinc stearate 1.5 kg Polydimethylsiloxane 500.0 g

[0045] The mass ratio of the raw materials of the B masterbatch is as follows:

[0046] Octabromoether 30.0 kg Octabromo-S ether 30.0 kg Antimony trioxide 20.0kg Atactic polypropylene 18.0 kg PTFE powder 1.0 kg Zinc stearate 500.0 g Polydimethylsiloxane 500.0 g

[0047] The preparation method of A masterbatch is as follows: Weigh all raw materials according to the above mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com