Neutron shielding material and preparation method thereof

A shielding material and neutron technology, applied in the field of neutron shielding materials and their preparation, can solve the problems of human health hazards, poor neutron shielding effect, high price, etc., and achieve strong shielding protection effect, good heat resistance and durability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

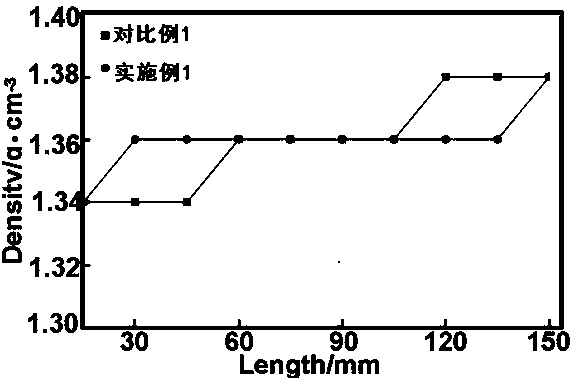

Embodiment 1

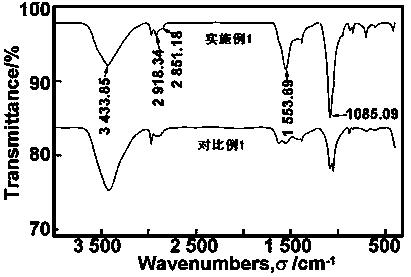

[0032] A kind of neutron shielding material, by weight percentage, comprises matrix 30%, platinum catalyst 30%, neutron absorber 30%, nitrogen expansion flame retardant 5%, tungsten powder 5%; Said matrix is made of phenylethylene Base silicone resin and phenyl hydrogen silicone oil are mixed at a mass ratio of 1:2.

[0033] The neutron absorber is boron carbide surface-modified with 3-aminopropyltriethoxysilane coupling agent, and its preparation method is as follows: 3-aminopropyltriethoxysilane and ethanol are Mix 1:8, adjust the pH of the solution to 4~5, according to the solid-to-liquid ratio of boron carbide to the total volume of the solution is 5mg:1mL, add boron carbide and ultrasonically disperse evenly, then hydrothermally react at 65°C for 4h, and filter the reactant with suction. Dry at 120°C to obtain boron carbide surface-modified with 3-aminopropyltriethoxysilane coupling agent.

[0034] The preparation method of the neutron shielding material comprises the ...

Embodiment 2

[0039] The present embodiment provides a neutron shielding material, which comprises 40% of a substrate, 20% of a platinum catalyst, 30% of a neutron absorber, 5% of magnesium hydroxide, and 5% of zinc powder by weight percentage; It is made by mixing vinyl silicone resin and phenyl hydrogen-containing silicone oil at a mass ratio of 1:1.

[0040] The neutron absorber is boron carbide surface-modified with 3-aminopropyltriethoxysilane coupling agent, and its preparation method is as follows: 3-aminopropyltriethoxysilane and ethanol are Mix 1:5, adjust the pH of the solution to 4~5, according to the solid-to-liquid ratio of boron carbide to the total volume of the solution is 3mg: 1mL, add boron carbide and ultrasonically disperse evenly, then hydrothermally react at 65°C for 4h, and filter the reactant with suction. Dry at 120°C to obtain boron carbide surface-modified with 3-aminopropyltriethoxysilane coupling agent.

[0041] The preparation method of the neutron shielding m...

Embodiment 3

[0046] The present embodiment provides a neutron shielding material, which comprises 40% of a substrate, 20% of a platinum catalyst, 38% of a neutron absorber, 1% of calcium hydroxide, and 1% of tungsten oxide in percent by weight; the substrate is composed of phenyl It is made by mixing vinyl silicone resin and phenyl hydrogen-containing silicone oil at a mass ratio of 1:3.

[0047] The neutron absorber is boron carbide surface-modified with 3-aminopropyltriethoxysilane coupling agent, and its preparation method is as follows: 3-aminopropyltriethoxysilane and ethanol are Mix at 1:10, adjust the pH of the solution to 4-5, according to the solid-to-liquid ratio of boron carbide to the total volume of the solution is 5mg: 1mL, add boron carbide and disperse evenly by ultrasonic, then hydrothermally react at 65°C for 4h, and filter the reactant with suction. Dry at 120°C to obtain boron carbide surface-modified with 3-aminopropyltriethoxysilane coupling agent.

[0048] The prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

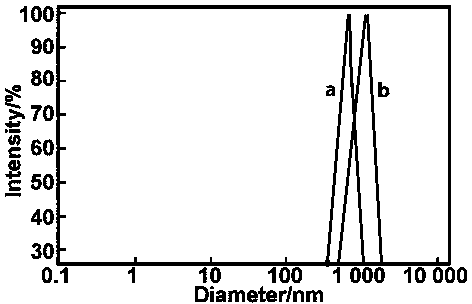

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com