A kind of Teflon coating for coating porous medium surface and preparation method thereof

A porous medium, Teflon technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. Incomplete and other problems, to achieve the effect of high practical value, increased uniformity, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

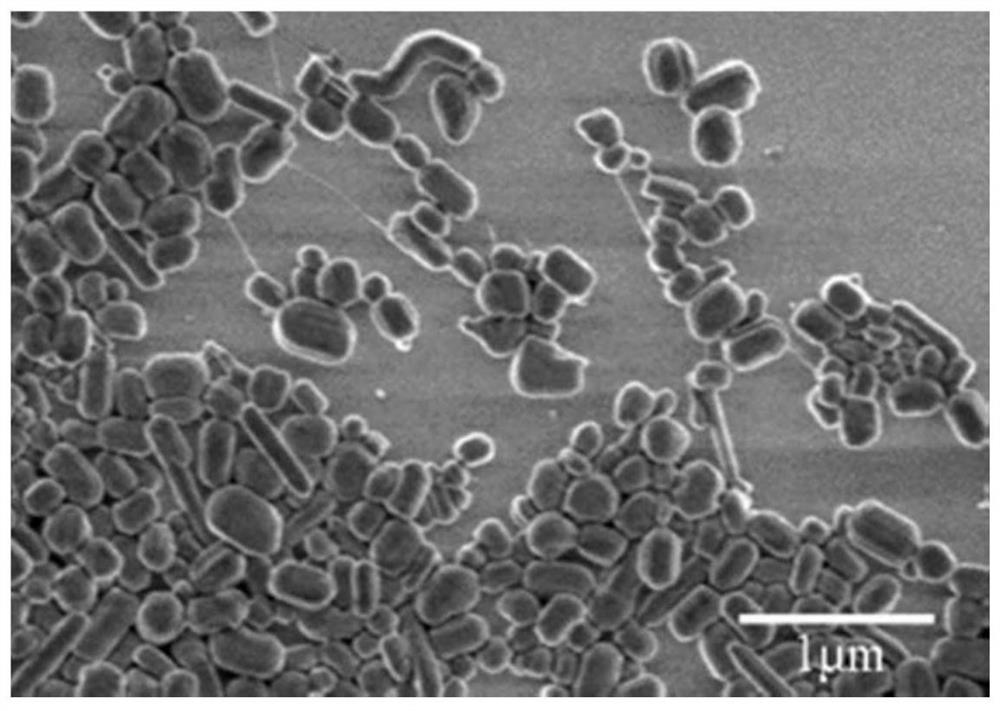

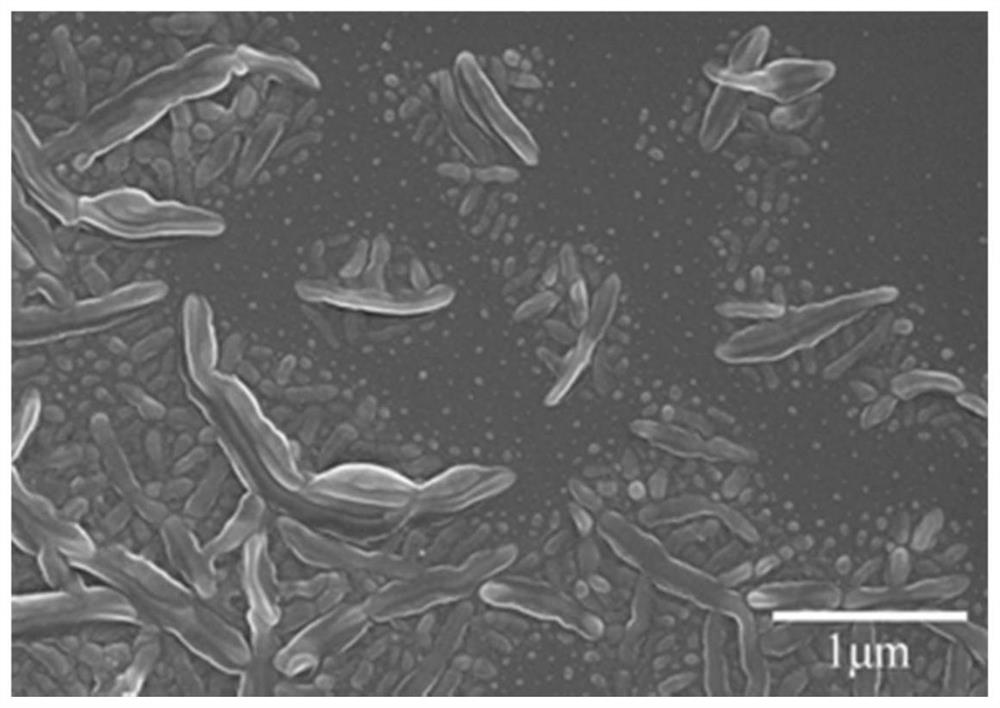

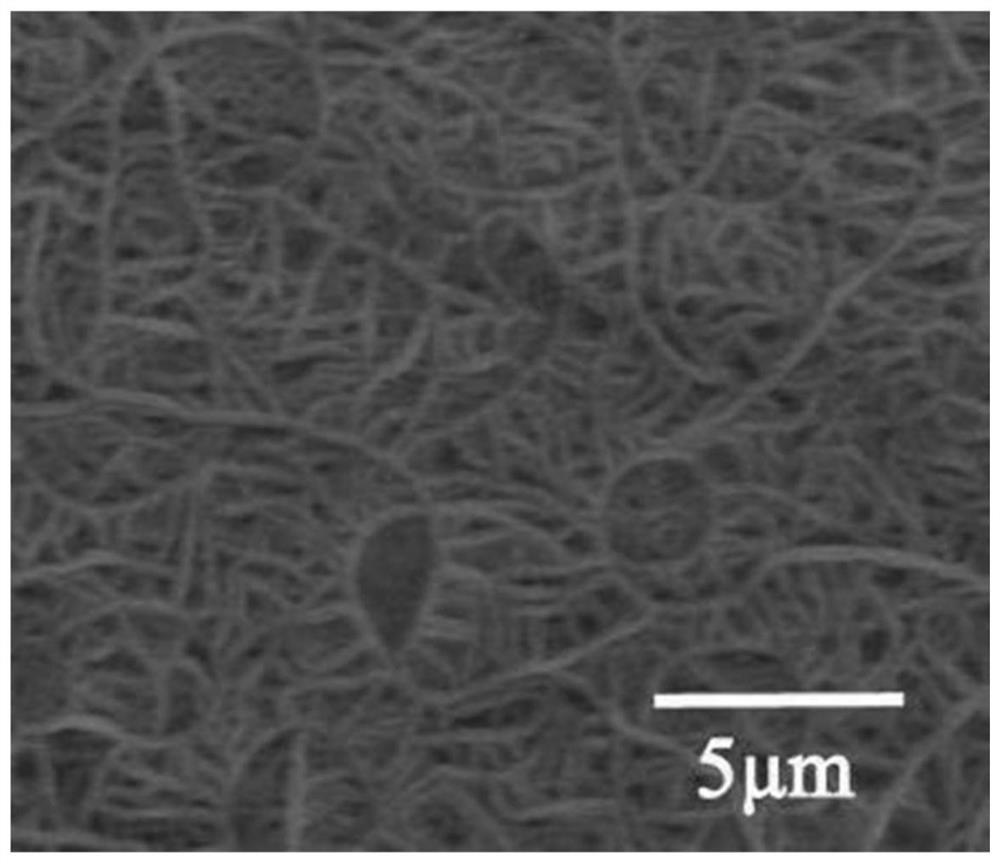

Image

Examples

preparation example Construction

[0026] In addition, in order to achieve the above object, the present invention also provides a kind of preparation method of above-mentioned Teflon coating, comprises the steps:

[0027] Step 1: Add pigments and fillers, water-based diluents, and dispersants to the disperser in sequence according to the weight percentage requirements, and stir (stirring speed 60-300r / min) to make it evenly mixed so that the particle size of the mixture is less than or equal to 10 μm, and then Filter with a filter screen of about 200 mesh to 500 mesh to obtain the paint pulp.

[0028] Step 2: In the stirring state (stirring speed 60-300r / min), add fluorocarbon emulsion and other various additives in sequence according to the weight percentage requirements, including wetting agent, film-forming additive, thickener, functional additive , PTFE micro-particles, after mixing evenly, the water-based fluorocarbon coating can be obtained. General condition PH value is 7-9.

[0029] Before use, accor...

Embodiment 1

[0032] The components and mass percentages of the Teflon coating used for spraying porous media provided in this embodiment are: 45% fluorocarbon emulsion, 30% pigment and filler, 0.3% wetting agent, 0.6% dispersant, and 2% coalescent %, thickener 1%, polytetrafluoroethylene particles 5%, functional additives 2%, water 14.1%. The fluorocarbon emulsion is a fluorine-containing acrylate emulsion (mass fraction is 75%, which is diluted with commercial finished thinner, and the thinner model is NY-200); the pigment and filler are rutile nano-TiO 2 , the particle size is 0.5 μm; the wetting agent is polydimethylsiloxane; the dispersant is carboxylic acid modified polyurethane; the film-forming aid is lauryl alcohol ester; the thickener is Hydroxyethyl cellulose; the functional additive is vinyltriethoxysilane; the water-based diluent is deionized water.

[0033]The preparation method comprises the following steps: adding pigments, fillers, dispersants, and water-based diluents int...

Embodiment 2

[0035] The components and mass percentages of the Teflon paint used for spraying porous media provided in this embodiment are: 50% fluorocarbon emulsion, 25% pigment and filler, 0.3% wetting agent, 0.5% dispersant, 5% film-forming aid %, thickener 1.5%, functional additive 2%, polytetrafluoroethylene microparticles 5%, water-based diluent 10.7%. Described fluorocarbon emulsion is fluorine-containing acrylate emulsion (mass fraction is 75%, adopts commercial product thinner to dilute, thinner signal is NY-200); Described pigment filler is rutile type nano-TiO 2 The wetting agent is polymethylalkylsiloxane; the dispersant is modified polyurethane; the coalescent is butanediol; the thickener is fumed silica and hydrophobic polyether compound, the ratio is 1:1; the functional auxiliary agent is propyltrimethoxysilane. The water-based diluent is water.

[0036] The preparation method comprises the following steps: adding pigments, fillers, dispersants, and water-based diluents in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com