Sulfur-tolerant shift methanation integrated catalyst and preparation method

A sulfur-resistant shift, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as retention, unindustrial application, etc. Low cost, low preparation cost, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

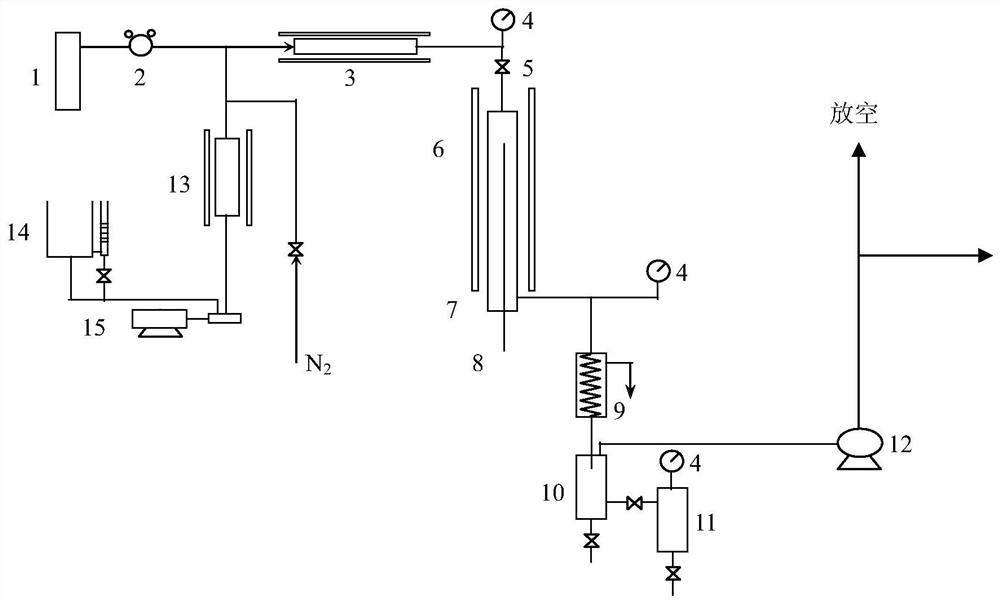

Method used

Image

Examples

Embodiment 1

[0031] (1) 15.8g of ammonium heptamolybdate dissolved in deionized water to obtain 40mL translucent solution A.

[0032] (2) 7.8g of cobalt nitrate, 4.6g of cerium nitrate, 3g oxalic acid and dilute nitric acid were added to 1mL 15mL deionized water to obtain a solution B;

[0033] (3) containing metatitanic acid 98g, 14g 80 # calcium aluminate, 3g Tian Qing powder uniformly dry blended were added to the solution A and B, uniformly kneaded, extruded and dried naturally, to obtain a catalyst after calcination semifinished 550 ℃.

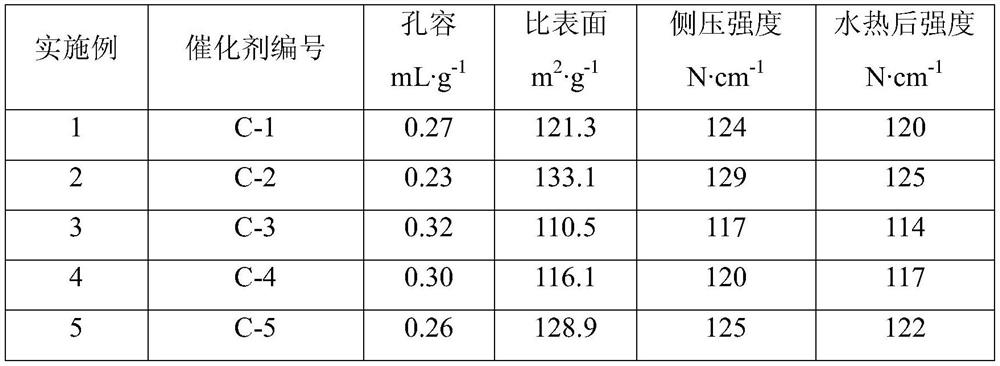

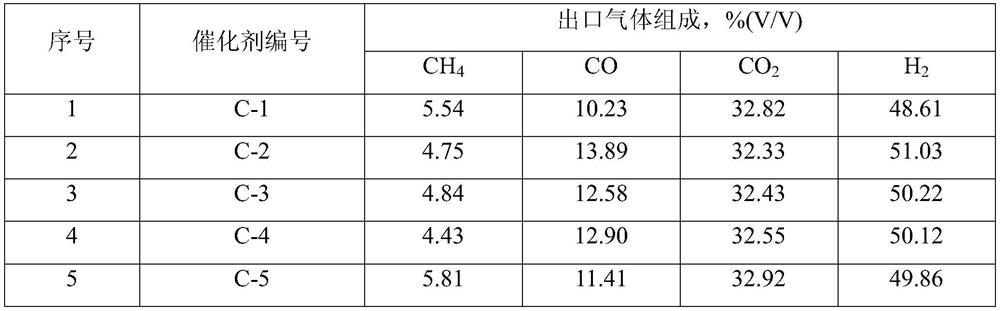

[0034] (4) The catalyst was placed in a semi-finished product in a closed reactor, to 500h -1 Into a space velocity air mixture containing 0.2% hydrogen sulfide, under the conditions of 200 ℃ and 10H is maintained, the temperature was lowered to room temperature, to obtain a finished catalyst C1. Strength, pore structure and catalytic activity data in Table 1.

Embodiment 2

[0036] (1) 18.5g of ammonium molybdate with four 50mL dissolved in deionized water to give a translucent solution A.

[0037] (2) 2.2g of cobalt nitrate, 2.5g of lanthanum nitrate, 4g of citric acid was added to 15mL deionized water to obtain a solution B;

[0038] (3) containing metatitanic acid 75.6g, 30g85 # calcium aluminate, 2g starch uniformly dry blended were added to the solution A and B, uniformly kneaded, extruded and dried naturally, to obtain a catalyst after calcination semifinished 700 ℃.

[0039] (4) The catalyst was placed in a semi-finished product in a closed reactor, to 1000h -1 Into a space velocity air mixture containing 0.1% hydrogen sulfide, under the conditions of 150 deg.] C and 15H is maintained, the temperature was lowered to room temperature, to obtain a finished catalyst C2. Strength, pore structure and catalytic activity data in Table 1.

Embodiment 3

[0041] (1) 9.8g of ammonium heptamolybdate dissolved in deionized water to obtain 35mL translucent solution A.

[0042] (2) 16.0g of cobalt nitrate, yttrium nitrate 3.68, 3g oxalic acid and 2mL of acetic acid were added to 20mL deionized water to give solution B.

[0043] (3) containing 74g of anatase, 13g75 # calcium aluminate, 6g Tian Qing powder uniformly dry blended were added to the solution A and B, uniformly kneaded, extruded and dried naturally, to obtain a catalyst after calcination semifinished 650 ℃.

[0044] (4) The catalyst was placed in a semi-finished product in a closed reactor, to 200h -1 Into a space velocity air mixture containing 0.3% hydrogen sulfide, under the conditions of 150 deg.] C and maintained for 20 h, after cooling to room temperature, to obtain a finished catalyst C3. Strength, pore structure and catalytic activity data in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com