Method for conducting coupling processing on high-concentration organic waste water and heavy metal waste water

A technology for organic wastewater and heavy metals, applied in chemical instruments and methods, separation methods, water/sewage treatment, etc., can solve the problems of difficult regeneration and elution of activated carbon, achieve solidification and effective resource utilization, simple preparation process, lightening The effect of adsorbent regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

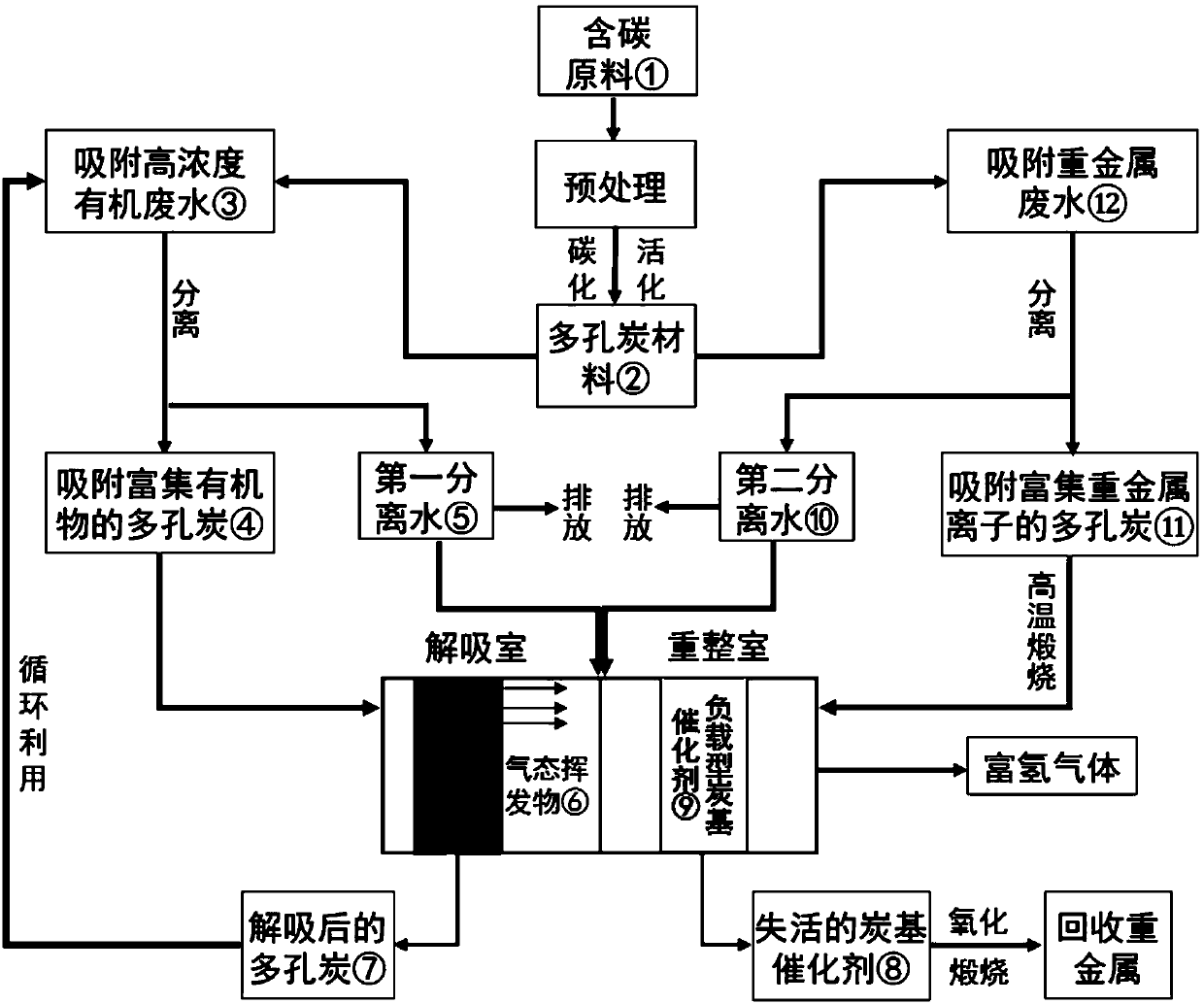

[0036] The method for coupling treatment of high-concentration organic waste water and heavy metal waste water of the present invention comprises the following steps:

[0037] Step 1. Preparation of carbon-containing raw material 1: using pine wood chips as raw materials, the pine wood chips were crushed, sieved, dried, and then carbonized to prepare carbon-containing raw material 1. The carbonization temperature was 700° C., and the carbonization treatment time was 2 hours.

[0038] Step 2. Preparation of porous carbon material 2: After mixing the biomass-based carbonized material prepared in step 1 with potassium hydroxide at a ratio of 1:4, react in a fixed-bed reactor, and wash with acid and water after the reaction The porous carbon material 2 is obtained by drying several times. During this process, the activation temperature of the carbon-containing raw material 1 is 700° C., and the reaction time is 2 hours.

[0039] Step 3. Coupling treatment of high-concentration org...

Embodiment 2

[0043] The method for coupling treatment of high-concentration organic waste water and heavy metal waste water of the present invention comprises the following steps:

[0044] Step 1. Preparation of carbon-containing raw material 1: using petroleum coke as a raw material, the petroleum coke is crushed, sieved, dried, and then carbonized to prepare carbon-containing raw material 1. The carbonization temperature is 700° C., and the carbonization treatment time is 2 hours.

[0045] Step 2. Preparation of porous carbon material 2: After mixing the petroleum coke carbonized material prepared in step 1 with potassium hydroxide at a ratio of 1:4, react in a fixed-bed reactor, and wash with acid and water after the reaction. The second time, dry the porous carbon material, the activation temperature of the carbonized material in this process is 700°C, and the reaction time is 2h.

[0046] Step 3. Coupling treatment of high-concentration organic wastewater and heavy metal wastewater: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com