Fatty acid modified acrylic emulsion and preparation method thereof

A technology of fatty acid modification and acrylic emulsion, which is applied in the field of synthetic resin materials, can solve the problems of low hardness, low gloss, and poor water resistance of the coating film, achieve high gloss, low reaction slag rate, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

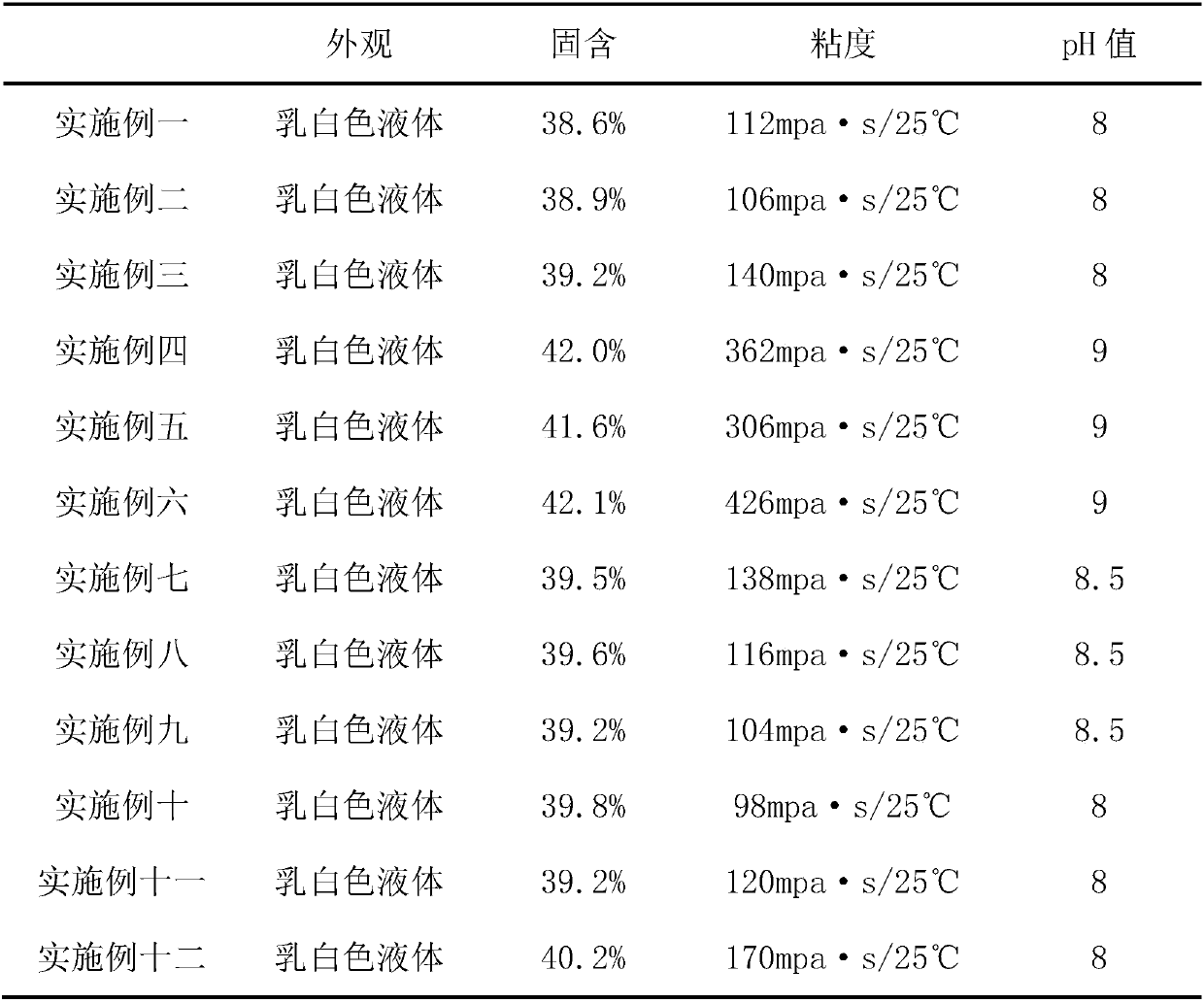

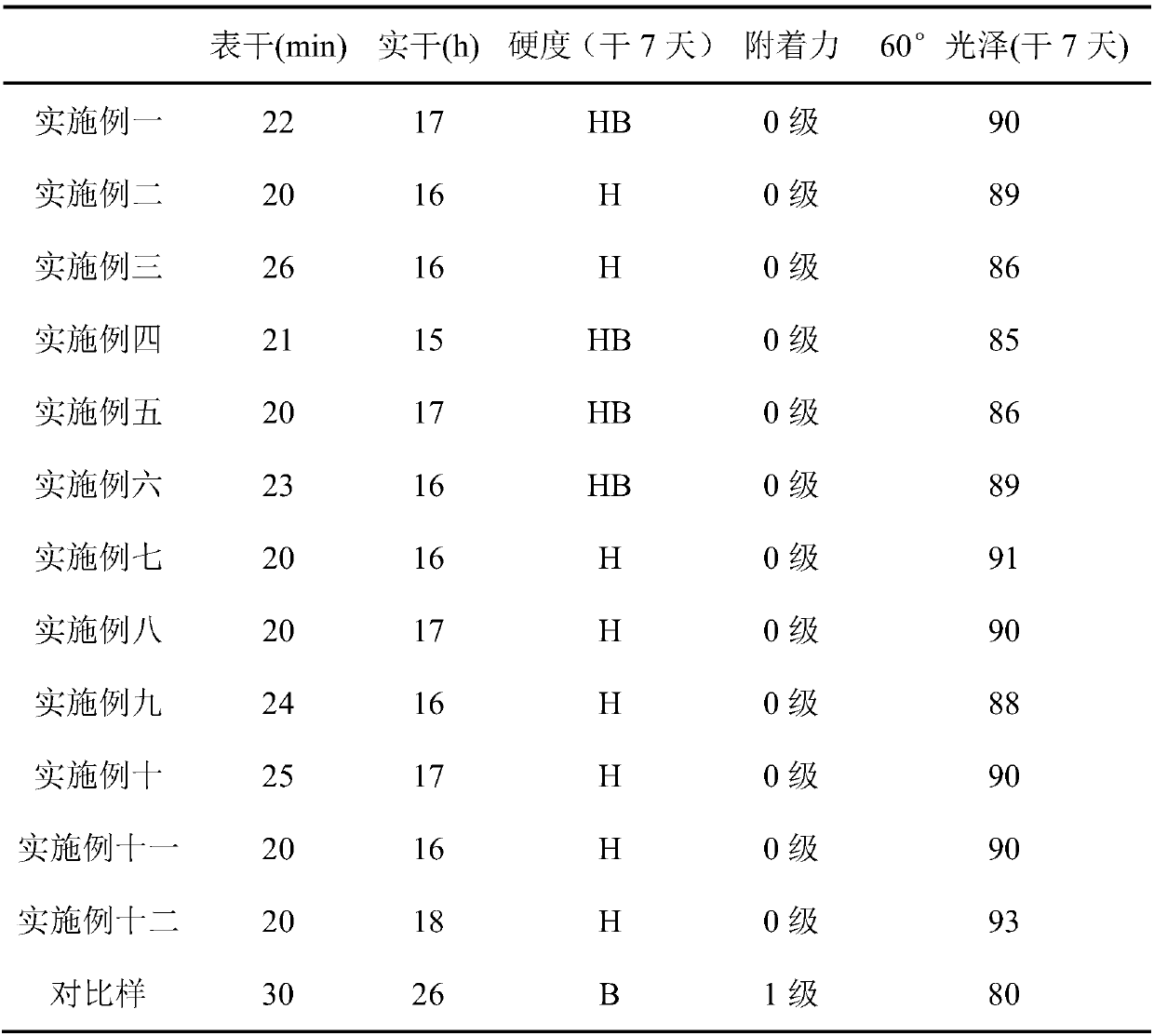

Examples

Embodiment 1

[0032] A fatty acid modified acrylic acid emulsion, its components and the parts by mass of the components are: fatty acid modified glycidyl methacrylate 25g, first emulsifier (OP-10, sodium lauryl sulfate) 2g, The second emulsifier (sodium lauryl sulfate) 0.5g, the first soft monomer (ethyl acrylate) 13g, the second soft monomer (butyl acrylate) 1g, the first hard monomer (styrene) 48g, The second hard monomer (acrylonitrile) 3g, functional monomer (acrylic acid) 1g, chain transfer agent (dodecanethiol) 0.5g, initiator (potassium persulfate) 0.1g, buffering agent (sodium bicarbonate) 0.1 g, water 150g.

[0033] Wherein the preparation method of fatty acid modified glycidyl methacrylate is as follows:

[0034] Mix unsaturated fatty acid (20 parts of soybean oleic acid), 20 parts of glycidyl methacrylate, catalyst (0.2 part of tetrabutylammonium bromide) and polymerization inhibitor (0.1 part of methyl hydroquinone) in the reactor, The reaction temperature is controlled at 90...

Embodiment 2

[0042] A kind of fatty acid modified acrylic acid emulsion, its component and component parts by mass are: fatty acid modified glycidyl methacrylate 25g, the first emulsifier (NP-10, dodecyl diphenyl ether disulfonic acid Sodium Acrylate) 2g, the second emulsifier (phosphorus-containing phosphate emulsifier) 0.5g, the first soft monomer (isooctyl acrylate) 12g, the second soft monomer (butyl acrylate) 1g, the first hard single Body (methyl methacrylate) 40g, second hard monomer (isobornyl acrylate) 3g, functional monomer (methacrylic acid) 1g, chain transfer agent (mercaptoethanol) 0.5g, initiator (ammonium persulfate) ) 0.1g, buffer (sodium bicarbonate) 0.1g, water 150g.

[0043] Wherein the preparation method of fatty acid modified glycidyl methacrylate is as follows:

[0044]Mix unsaturated fatty acid (20 parts of linoleic acid), 20 parts of glycidyl methacrylate, catalyst (0.2 part of triphenylphosphine) and polymerization inhibitor (0.1 part of isooctyl acrylate) in a ...

Embodiment 3

[0052] A kind of fatty acid modified acrylic acid emulsion, its component and component mass parts and numbers are: fatty acid modified glycidyl methacrylate 25g, the first emulsifier (nonylphenol polyoxyethylene ether ammonium sulfate, dodecane Sodium phenyl sulfonate) 2g, the second emulsifier (phosphorus-containing phosphate emulsifier) 0.5g, the first soft monomer (octearyl acrylate) 12g, the second soft monomer (octearyl acrylate) 1g, The first hard monomer (isobornyl acrylate) 40g, the second hard monomer (acrylonitrile) 3g, the functional monomer (acrylic acid, γ-methacryloxypropyltrimethoxysilane) 2g, chain transfer Agent (mercaptoethanol) 0.5g, initiator (ammonium persulfate) 0.1g, buffer (sodium bicarbonate) 0.1g, water 150g.

[0053] Wherein the preparation method of fatty acid modified glycidyl methacrylate is as follows:

[0054] Put unsaturated fatty acid (20 parts of oleic acid), 20 parts of glycidyl methacrylate, catalyst (0.2 part of benzyltriethylammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com