Gasoline engine lubricating oil composition and preparation method thereof

A technology of lubricating oil composition and derivatives, applied in lubricating compositions, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve problems such as toxicity, flammability and explosion, catalyst poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

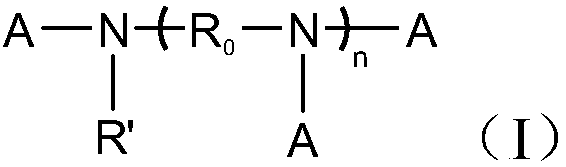

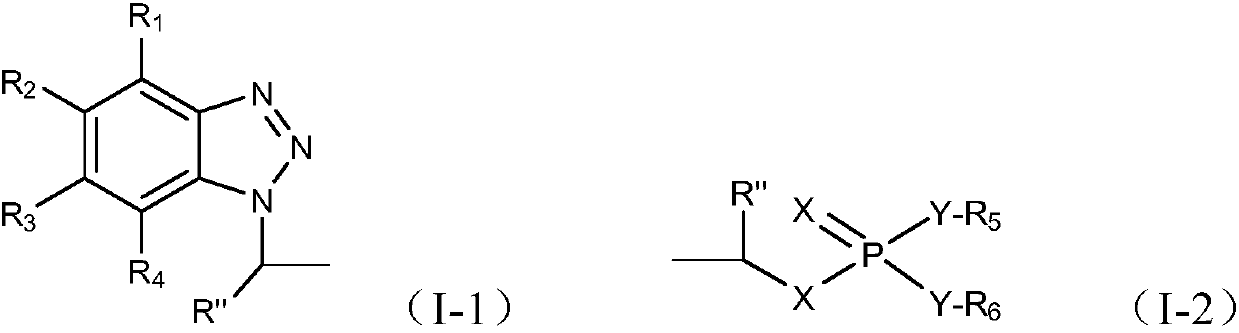

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

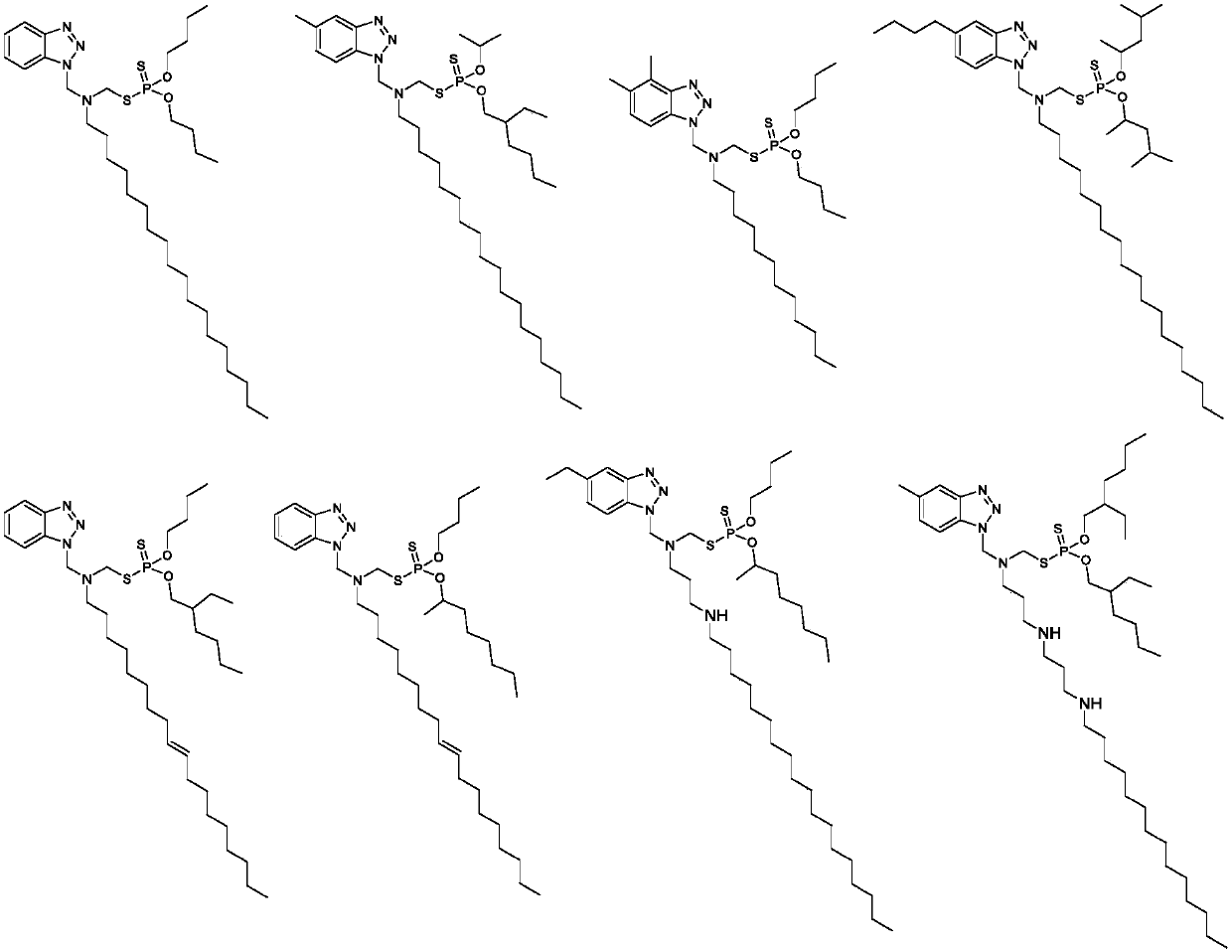

Embodiment 1

[0180]

[0181]Under a nitrogen protective atmosphere, in a 250ml four-necked flask equipped with a stirrer, a thermometer, a condenser and a water separator, add 23.01 grams (86mmol) of octadecylamine and 20.27 grams (250mmol) of formaldehyde solution, 12.51 grams (105mmol) Benzotriazole and 32.79 g (110 mmol) of n-butyl 2-ethylhexyl dithiophosphoric acid were stirred rapidly, and the temperature was raised to 90° C. for 5 h. After the reaction was completed, the remaining water was distilled off under reduced pressure, cooled to room temperature, settled for 24 hours, filtered to remove impurities, and separated by column chromatography to obtain the final product, marked as M-1.

[0182] Product characterization data are as follows:

[0183] 1 H NMR (300MHz, CDCl 3 ): δ0.88(9H), 1.03-1.72(40H), 2.12-3.93(10H), 4.20-4.54(2H), 5.18-6.17(4H), 7.18-8.08(4H);

[0184] C 38 h 69 N 4 o 2 P.S. 2 Calculated for C 64.37, H 9.81, N 7.90, O 4.51, P 4.37, S 9.04; found: C 64....

Embodiment 2

[0186]

[0187] Under a nitrogen protective atmosphere, in a 500ml four-necked flask equipped with a stirrer, a thermometer, a condenser and a water separator, add 133.81 grams (410mmol) of octadecylpropylenediamine and 25.8 grams (860mmol) of paraformaldehyde, 55.89 Gram (380 mmol) of 5-ethylbenzotriazole and 134.15 g (450 mmol) of n-butyl 1-methylheptyl dithiophosphoric acid were stirred rapidly, and the temperature was raised to 110° C. for 4 hours. After the reaction was completed, the remaining water was distilled off under reduced pressure, cooled to room temperature, settled for 24 hours, filtered to remove impurities, and separated by column chromatography to obtain the final product, marked as M-2.

[0188] Product characterization data are as follows:

[0189] 1 H NMR (300MHz, CDCl 3 ): δ0.88(6H), 1.03-1.93(57H), 2.43-2.74(8H), 3.46-4.10(4H), 4.24-4.63(2H), 5.31-6.20(2H), 7.19-7.82(3H) ;

[0190] C 43 h 82 N 5 o 2 P.S. 2 Calculated for C 64.86, H 10.38, N...

Embodiment 3

[0192]

[0193] Under a nitrogen protective atmosphere, in a 500ml four-necked flask equipped with a stirrer, a thermometer, a condenser and a water separator, add 45 grams of polyisobutylene amine (number average molecular weight is about 600) and 9 grams (300mmol) of paraformaldehyde , 10.16 grams (85 mmol) of benzotriazole and 150 mL of toluene were stirred rapidly, the temperature was raised to 100 ° C, 24.4 grams (100 mmol) of di-n-butyldithiophosphoric acid were added dropwise, and the reaction was carried out at constant temperature for 5 hours. After the reaction was completed, the solvent and residual water were distilled off under reduced pressure, impurities were removed by filtration, and the final product was separated by column chromatography, which was marked as M-3.

[0194] Product characterization data are as follows:

[0195] 1 H NMR (300MHz, CDCl 3 ): δ0.86(9H), 0.97-1.91(86H), 3.46-4.87(6H), 5.23-6.35(2H), 7.19-8.08(4H);

[0196] Element content dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com