A lithium-air battery based on lithium alloy negative electrode

A technology of lithium-air batteries and lithium alloys, applied in battery electrodes, fuel cell-type half-cells, secondary battery-type half-cells, circuits, etc., can solve problems such as short cycle life, low energy efficiency, and poor safety. Achieve the effect of optimizing the negative electrode interface, inhibiting the occurrence of lithium dendrites, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

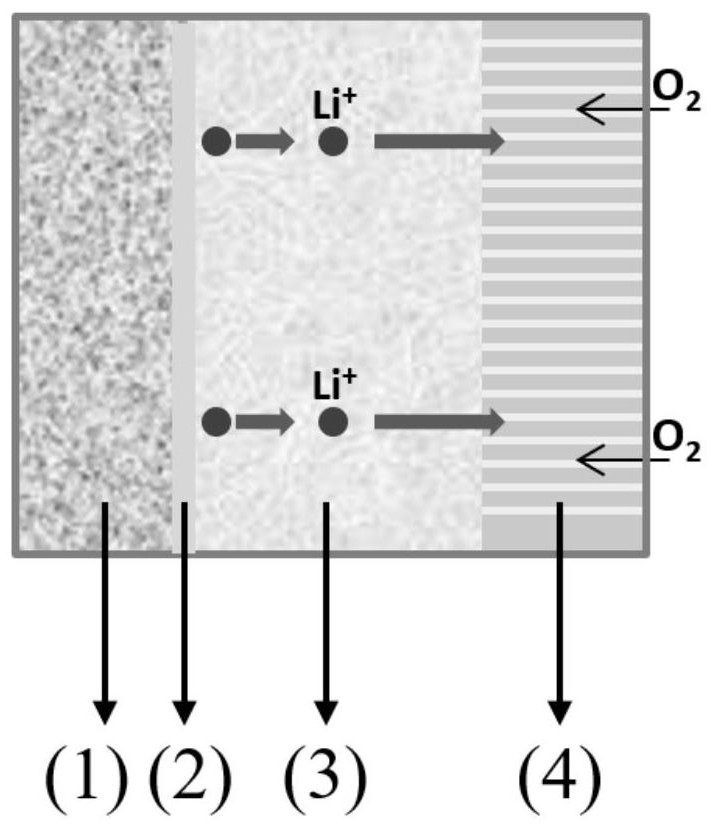

[0044] The porous air electrode, electrolyte system, and lithium-aluminum alloy negative electrode used in lithium-air batteries are as follows:

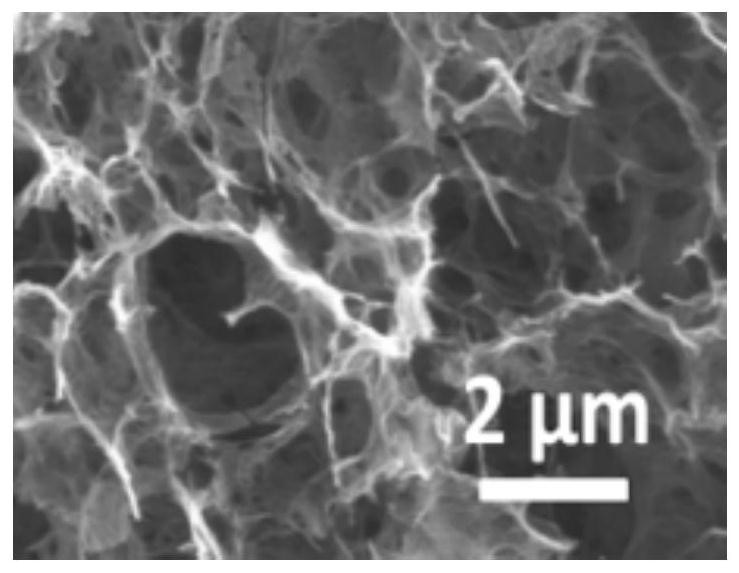

[0045] Porous air electrode: Nitrogen-doped graphene airgel material is used as a porous air electrode catalyst, loaded on the surface of carbon paper, and its loading amount is 0.2mg. For detailed preparation methods, see: HuanhuanGuo, GuangmeiHou, JiangguangGuo, XiaohuaRen, Xiaoxin Ma, Linna Dai, ShiruiGuo, Jun Lou, JinkuiFeng, Lin Zhang, Pengchao Si, and LijieCi. Enhanced Cycling Performance of Li-O 2 Battery by Using a Li3PO4-Protected Lithium Anode in DMSO-Based Electrolyte. ACS Appl. Energy Mater. 2018, 1, 5511−5517.

[0046] Electrolyte solution system: 1M LiTFSI lithium salt was dissolved in TEGDME solvent to form an electrolyte solution, and 100 microliters of the electrolyte solution was dropped on the glass fiber separator.

[0047] Lithium alloy negative electrode: a lithium-aluminum alloy with an aluminum content of 2...

Embodiment 2

[0056] The porous air electrode, electrolyte system, and lithium alloy negative electrode used in lithium-air batteries are as follows:

[0057] Porous air electrode: Nitrogen-sulfur double-doped graphene airgel material is used as a porous air electrode catalyst, which is loaded on the surface of carbon paper with a loading amount of 0.3 mg.

[0058] Electrolyte solution system: 1M LiFSI lithium salt was dissolved in TEGDME solvent to form an electrolyte solution, and 100 microliters of the electrolyte solution was dropped on the glass fiber separator.

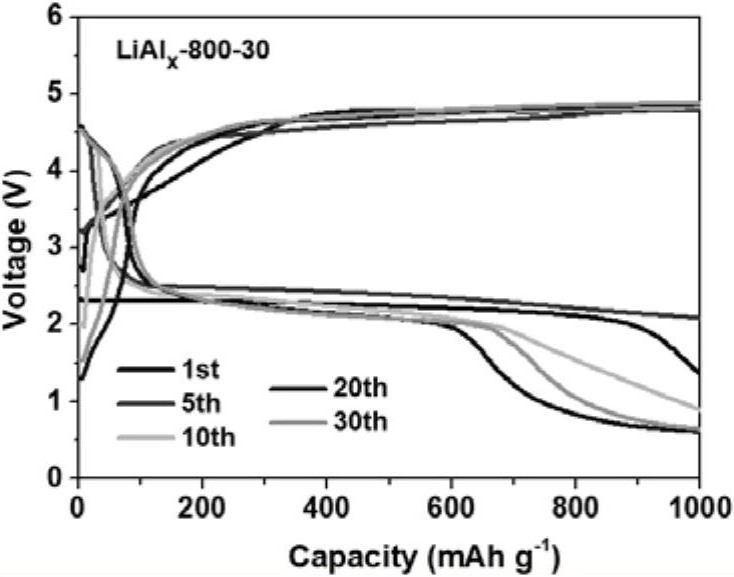

[0059] Lithium alloy negative electrode: a lithium aluminum alloy with an aluminum content of 5wt% is used as the negative electrode, and the porous air electrode, electrolyte and negative electrode are assembled in an Ar-containing atmosphere glove box to form a lithium-air battery. The lithium-air cell is vented to pure argon, and at 1.5 mAcm -2 Pretreatment was carried out for 40 cycles at a higher current density to form...

Embodiment 3

[0061] The porous air electrode, electrolyte system, and lithium alloy negative electrode used in lithium-air batteries are as follows:

[0062] Porous air electrode is the same as embodiment 1;

[0063] Electrolyte system is the same as embodiment 1;

[0064] Lithium alloy negative electrode: A lithium-magnesium alloy with a magnesium content of 3wt% is used as the negative electrode, and the porous air electrode, electrolyte and negative electrode are assembled in an Ar-containing atmosphere glove box to form a lithium-air battery. The Li-air battery is supplied with pure oxygen and at 2.0 mAcm -2 Pretreatment was carried out for 20 cycles at a higher current density, and a composite protective film containing magnesium oxide was formed on the surface of the lithium-magnesium alloy in situ, and then the battery was placed in a pure oxygen atmosphere at 0.15 mA cm -2 Normal electrochemical cycle tests were performed at lower current densities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com