Method for preparing artificial muscle tendons by using biological three-dimensional printing and electrospinning technology

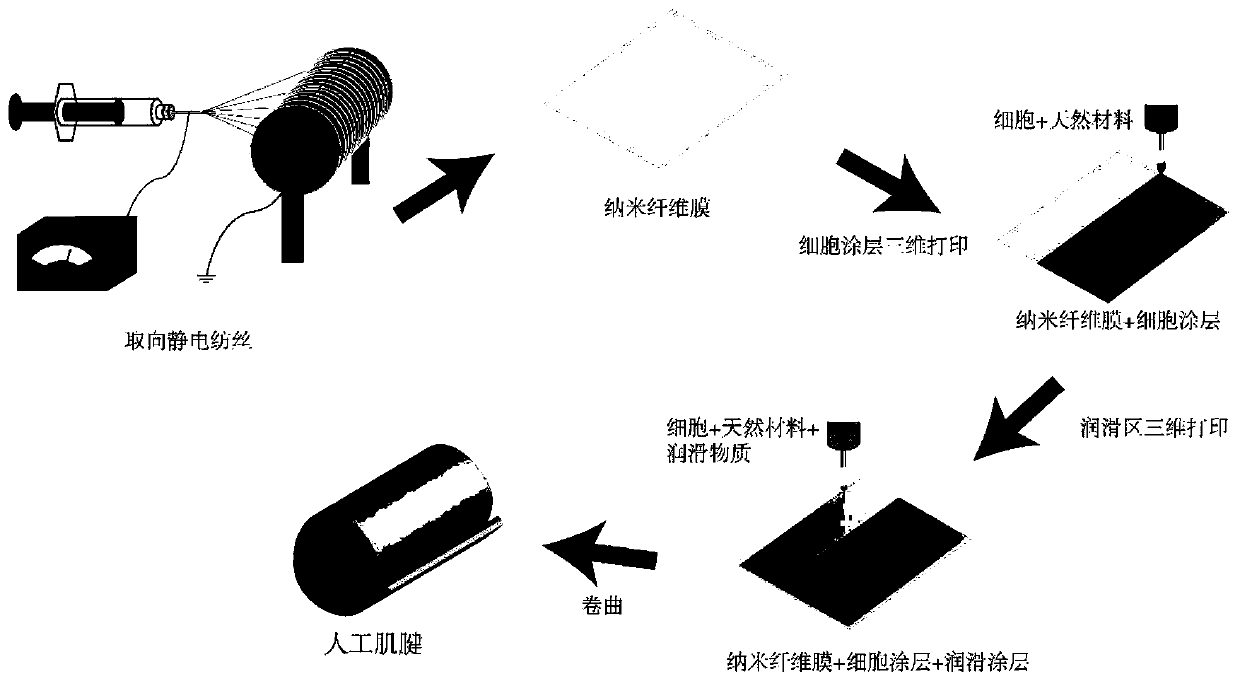

An electrospinning technology and three-dimensional printing technology are applied in the field of artificial muscle preparation by using biological three-dimensional printing and electrospinning technology, which can solve the problems of difficult to achieve rapid repair of damaged tissue, affecting the normal function of tendon, low colonization efficiency, etc. The effect of tendon repair and normal function recovery, and the production method is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] S2, the preparation of nanofiber film;

[0034] S3, the preparation of cell coating;

[0035] S4. Treatment of the nanofibrous membrane-cell coating.

[0036] Specifically, for the cultivation of seed cells in the S1 step, tendon stem cells are cultured in an incubator with DMEM medium containing 10% fetal bovine serum, bone marrow stem cells and adipose stem cells are cultured with 10% fetal bovine serum, connective tissue growth factor CTGF25ng / ml, ascorbic acid 25uM α-MEM medium cultured in the incubator.

[0037] Specifically, the incubator used in the S1 step contains 5% CO 2 , the temperature in the incubator is 37°C.

[0038] Specifically, the preparation of the nanofiber membrane in the step S2 includes the following steps:

[0039] S21. Preparation of materials: Measure an appropriate amount of biopolymer material and electrospinning solvent, and then put natural materials into the electrospinning solvent for mixing. The mass fraction of biopolymer materia...

Embodiment 1

[0050] Polycaprolactone, a polymer material, is dissolved in hexafluoroisopropanol solvent, with a total mass fraction of 12%. Adjust the electrospinning process parameters: turn on the orientation, the flow rate of the propulsion pump is 1.5mL / h, the external high voltage is 10kv, the receiving distance is 10cm, and the nanofiber film is obtained by electrospinning;

[0051] Mix tendon stem cells with 10g of sodium alginate gel and add them into the cylinder of the 3D printer. Set it to 0 / 90°, print on the surface of the obtained nanofiber membrane, start the printing program, and print a single-layer rectangular bracket with a length of 3 cm and a width of 1 cm;

[0052] Mix tendon stem cells, cytokine BMP7, and 10 g of sodium alginate gel into the barrel of the three-dimensional printer. The printing temperature is set at 37 ° C, the diameter of the print head is 200 μm, the layer height is 200 μm, and the air pressure of the barrel is 800KPa. The printing path is set to 0...

Embodiment 2

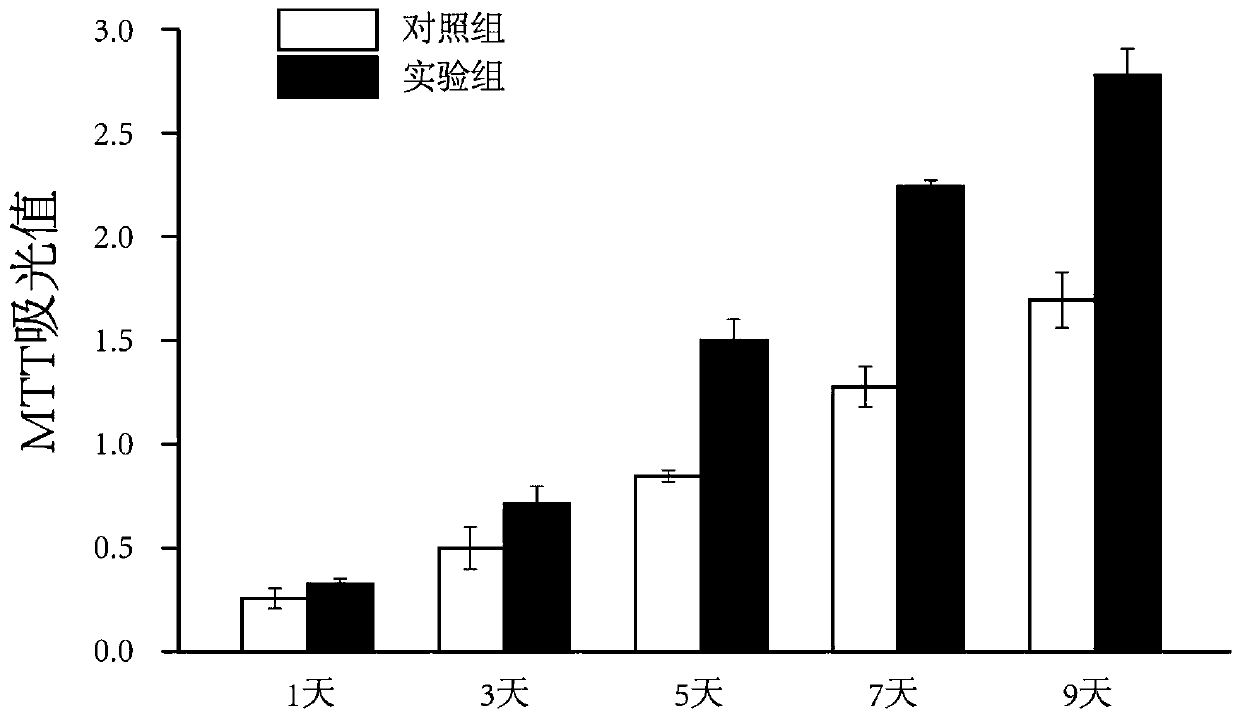

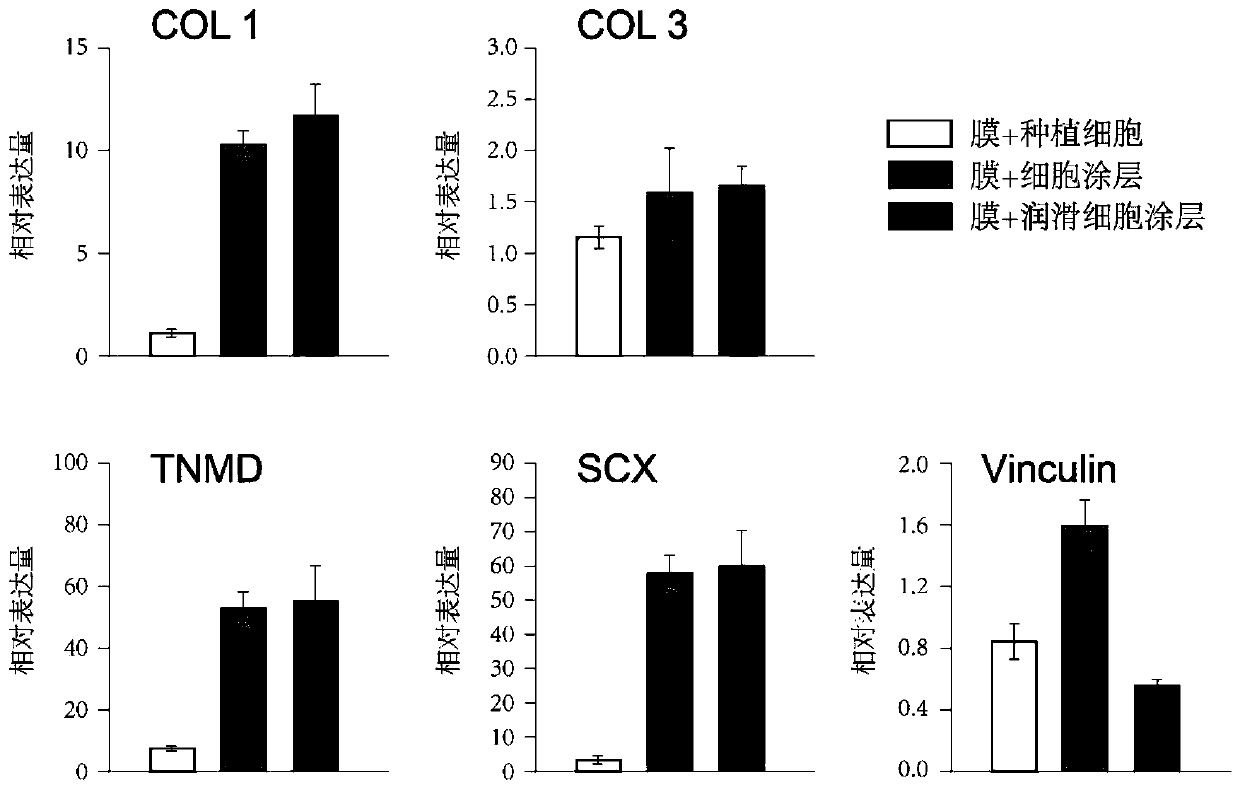

[0055] The biocompatibility of the tendon scaffold prepared by three-dimensional bioprinting technology combined with electrospinning technology was characterized. The obtained nanofiber membrane was curled and placed in an incubator for culture. A single layer of nanofiber membrane was planted with tendon stem cells on the surface as a control. For comparison, after 1, 3, 5, 7 and 9 days of culture, the tenocyte viability in the tendon scaffold was detected by MTT method. The tenocytes on the fibrous membrane had good proliferation behavior, and the cell viability was better, and the proliferation behavior was more significant than that of the control group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com