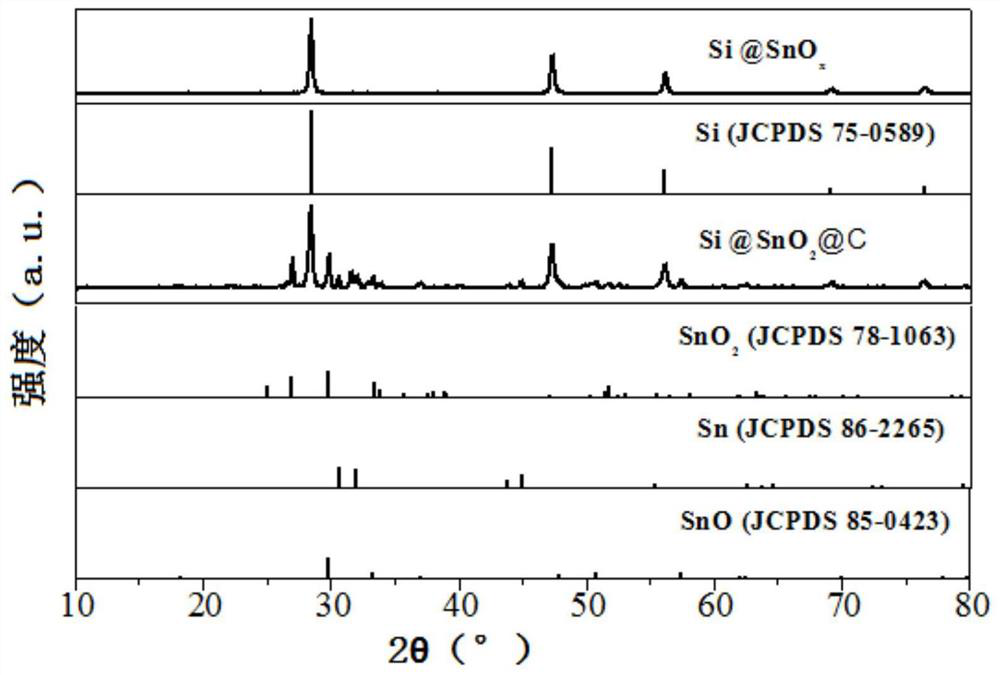

A high-performance si@sno 2 @cComposite materials and their preparation methods and applications

A composite material, high-performance technology, applied in structural parts, electrical components, battery electrodes, etc., to achieve the effects of cheap raw materials, improved electrochemical performance, and obvious cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

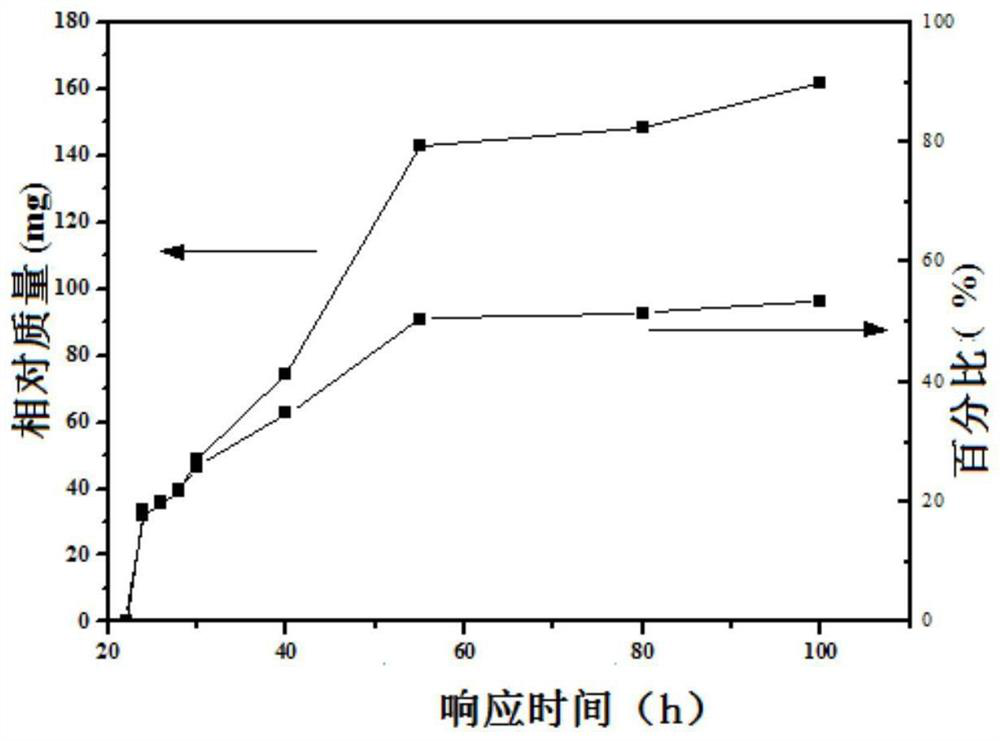

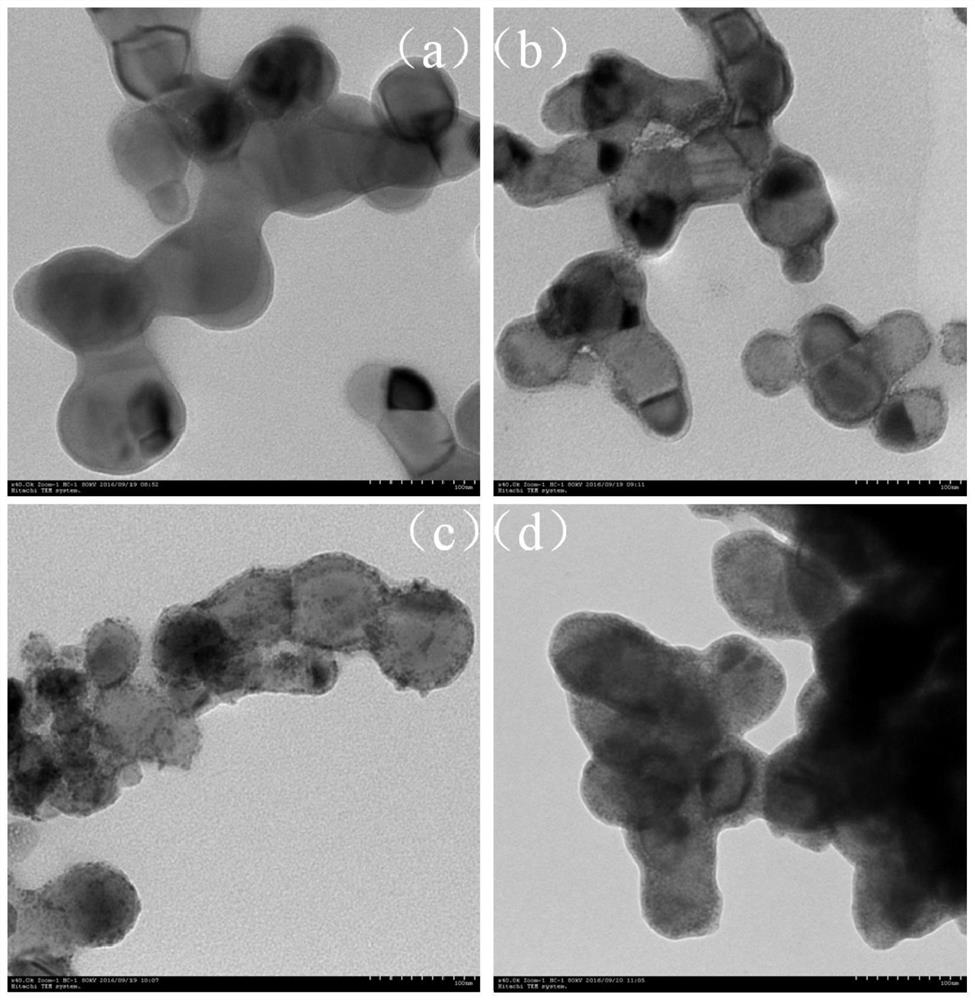

Embodiment 1

[0040] (1) Take 1.0 g of Si powder and treat it at 600 °C in a muffle furnace for 1 h to prepare a thermally oxidatively modified Si material; (2) The modified Si nanoparticles are dispersed in 80 mL of deionized water for 30 min, and then added Sonicate 0.08g thioglycolic acid for 10min, add 1mL concentrated hydrochloric acid for 5min, add 0.2g urea for 5min; finally add 0.7g SnCl 2, ultrasonication for 10 min; stirring at room temperature 25°C for 40 h; suction filtration after the reaction, washing twice with water and once with ethanol. Vacuum drying at 70°C for 2h to obtain Si@SnO 2 Structural material; (3) Mix 100mL (28.6mL of deionized water and 71.4mL of ethanol) in an aqueous solution, and stir it evenly by ultrasonic. Then 0.2g Si@SnO obtained by the above steps 2 Disperse in it and stir ultrasonically for 20min; add 1.2gCTAB, 0.175g resorcinol, and 0.3mL ammonia water to the above solution, and ultrasonically stir for 30min; then place it in an oil bath at 45°C an...

Embodiment 2

[0044] (1) Get 1.0g of Si powder and treat it with hydrogen peroxide-sulfuric acid mixed solution for 1h to prepare chemical oxidation modified Si material;

[0045] (2) The modified Si nanoparticles were dispersed in 80 mL of deionized water for 30 min, then 0.035 g of thioglycolic acid was added for 10 min, 0.2 mL of concentrated hydrochloric acid was added for 5 min, and 0.1 g of urea was added for 5 min; finally, 0.2 g SnCl 2 , sonicated for 10min; stirred at 20°C for 72h. After the reaction, filter with suction, wash twice with water and once with ethanol; dry in vacuum at 70°C for 2h to obtain Si@SnO 2 Structural materials;

[0046] (3) Mix 100mL (10mL of deionized water and 90mL of ethanol) in an aqueous solution, and ultrasonically stir it evenly; then 0.2g of Si@SnO obtained in the above steps 2 Disperse in it and stir ultrasonically for 20 minutes; add 0.3g CTAB, 0.0875g resorcinol, and 0.1mL ammonia water into the above solution, and stir ultrasonically for 30 mi...

Embodiment 3

[0050] (1) Take 1.0g of Si powder and treat it with PVP solution for 1h to prepare surfactant-modified Si material;

[0051] (2) The modified Si nanoparticles were dispersed in 80 mL of deionized water and sonicated for 30 minutes, then 0.15 g of thioglycolic acid was added for 10 minutes of sonication, 2 mL of concentrated hydrochloric acid was added for 5 minutes of sonication, and 0.5 g of urea was added for 5 minutes of sonication. Finally add 1.0gSnCl 2 , ultrasonication for 10 min; stirring at 60°C for 0.5 h; suction filtration after the reaction, washing twice with water and once with ethanol. Vacuum drying at 70°C for 2h to obtain Si@SnO 2 Structural materials;

[0052] (3) Mix 100 mL (50 mL of deionized water and 50 mL of ethanol) in an aqueous solution, and stir it evenly by ultrasonic. Then 0.2g Si@SnO obtained by the above steps 2 Disperse in it and stir ultrasonically for 20min; add 3.6g CTAB, 0.7g resorcinol, and 1.2mL ammonia water into the above solution, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com