Preparation and application of tin-doped, induced and synthesized mixed-phase molybdenum disulfide-chlorella derived carbon composite material

A molybdenum disulfide, composite material technology, applied in nanotechnology, electrochemical generators, secondary batteries, etc. for materials and surface science, to achieve the effects of wide sources, increased electrical conductivity, and improved electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Weigh 2g of chlorella, 5g of phosphomolybdic acid and 1.5g of stannous sulfate into 0.4L of distilled water, stir for 12 hours, centrifuge once and dry in an oven at 60°C;

[0036] 2) after step 1) the dark green massive solid gained and the sulfur powder of 2 times of its quality are mixed, in Ar 95%\H 2 Calcined in a 5% atmosphere tube furnace at 600°C for 2 hours, and collected a black solid sample, which is a 1T-2H mixed-phase few-layer molybdenum disulfide-chlorella-derived carbon composite material;

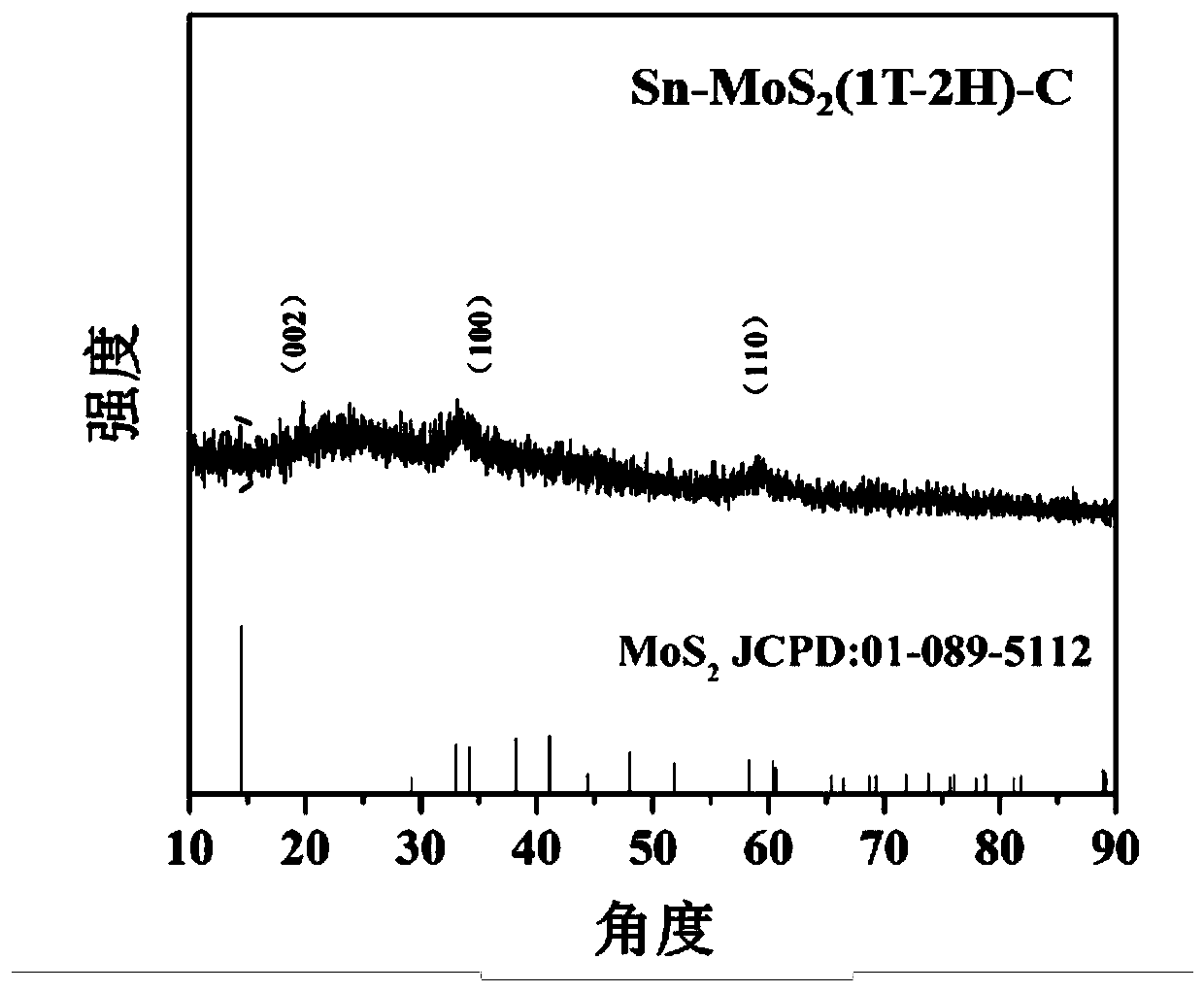

[0037] The 1T-2H miscible few-layer molybdenum disulfide-chlorella-derived carbon composite material prepared above was determined by XRD, and obtained figure 1 The XRD pattern of the 1T-2H miscible few-layer molybdenum disulfide-chlorella-derived carbon composite, as figure 1 shown. Depend on figure 1 It can be seen that the synthesized material is molybdenum disulfide, and its diffraction peak position matches the standard spectrum of molybdenum disulfide (J...

Embodiment 2

[0040] 1) Weigh 2g of chlorella, 7.5g of ammonium molybdate and 2.5g of stannous chloride into 0.4L of distilled water, stir for 12 hours, centrifuge once and dry in an oven at 80°C;

[0041] 2) after step 1) the dark green massive solid gained and the sulfur powder of 2 times of its quality are mixed, in Ar 95%\H 2 Calcined at 650°C for 2 hours in a 5% atmosphere tube furnace, and collected a black solid sample, which is a 1T-2H mixed-phase few-layer molybdenum disulfide-chlorella-derived carbon composite material;

[0042] 3) The 1T-2H mixed-phase few-layer molybdenum disulfide-chlorella-derived carbon composite material prepared in this example: conductive agent super P carbon: binder CMC is mixed and ground according to the mass percentage of 8:1:1 and evenly coated Make the working electrode on the copper foil, the metal sodium sheet is the counter electrode and the reference electrode, 1mol / L NaClO 4 / PC+EC is assembled into a button cell for the electrolyte; all assem...

Embodiment 3

[0044] 1) Weigh 2g of chlorella, 5g of phosphomolybdic acid and 1g of stannous sulfate into 0.6L of distilled water, stir for 12 hours, centrifuge once and dry in an oven at 60°C;

[0045] 2) after step 1) the dark green massive solid gained and the sulfur powder of 2 times of its quality are mixed, in Ar 95%\H 2 Calcined in a 5% atmosphere tube furnace at 500°C for 2 hours, and collected a black solid sample, which is a 1T-2H mixed-phase few-layer molybdenum disulfide-chlorella-derived carbon composite material;

[0046] The 1T-2H mixed-phase few-layer molybdenum disulfide-chlorella-derived carbon composite material prepared in this example: conductive agent super P carbon: binder CMC is mixed and ground according to the mass percentage of 80:10:10 and evenly coated on the copper Foil as working electrode, metal sodium sheet as counter electrode and reference electrode, 1mol / L NaClO 4 / PC+EC is assembled into a button cell for the electrolyte; all assemblies are carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com