Lithium-oxygen/air cell and preparation method thereof

An air battery and air electrode technology, which is applied to battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc. Secondary damage and other problems, to achieve the effect of good industrial value and commercial prospects, good operation stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

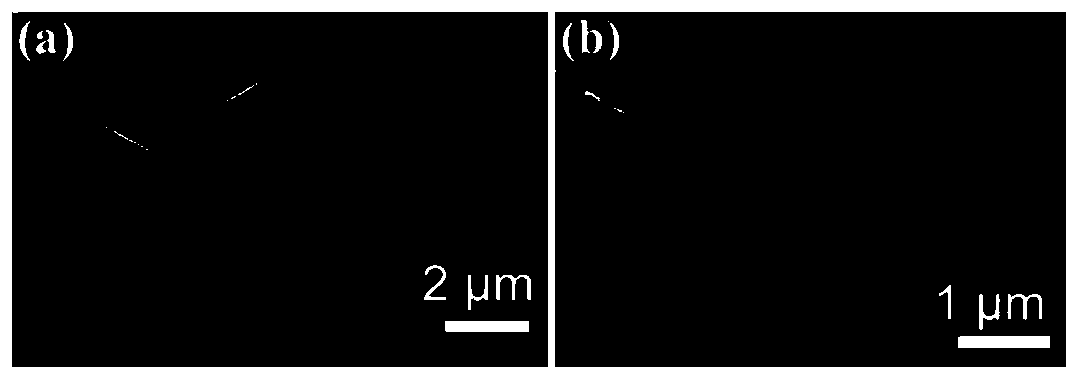

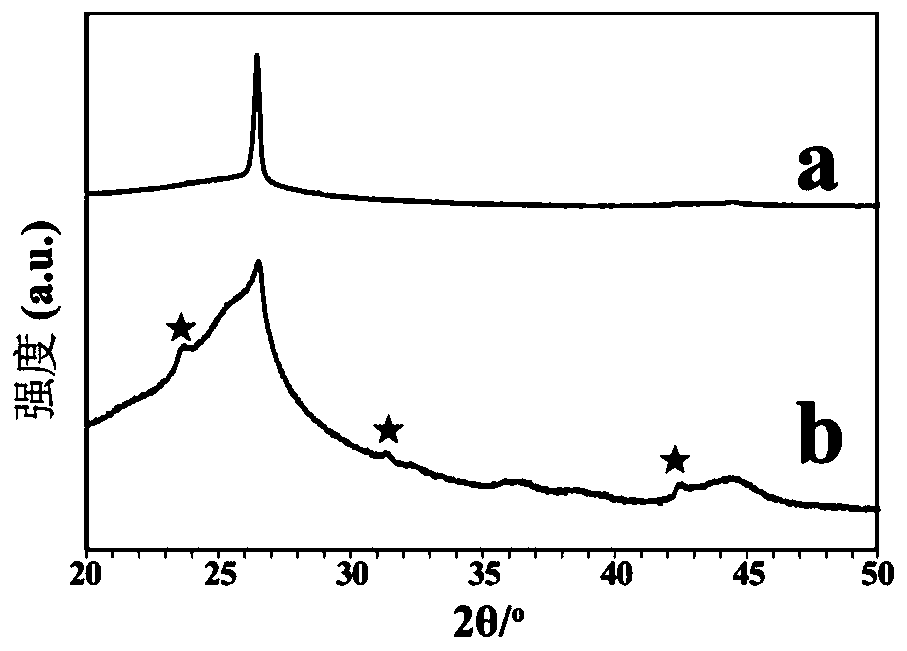

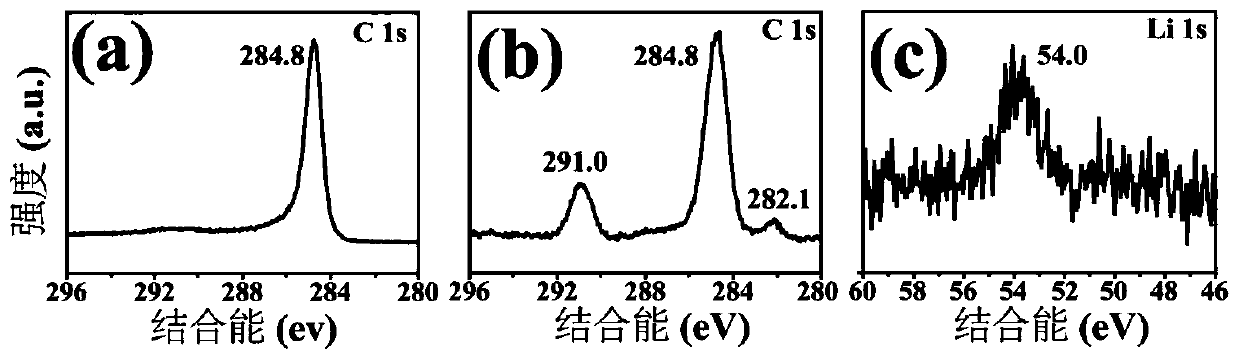

Embodiment 1

[0046] (S1), mix 10mg Ketjen Black with 110mg concentration of 1wt% polyvinylidene fluoride solution, the solvent of polyvinylidene fluoride solution is N-methylpyrrolidone, continue to add N-methylpyrrolidone solvent until the dispersion system is 1mL, ultrasonically dispersed until uniform, and evenly coated on the substrate, vacuum-dried at 110°C for 12h to obtain the original electrode material;

[0047] (S2), assemble the metal ion battery in an argon-filled glove box, using a CR2032 button battery case with holes on one side, the hole diameter is 2mm, and the hole density is 5 to 8 holes / cm 2 , the positive electrode is a lithium sheet, the negative electrode is the original electrode material prepared in (S1) step, the electrolyte solution is a tetraethylene glycol dimethyl ether solution of 1M bistrifluoromethanesulfonimide lithium, and the diaphragm is a glass fiber diaphragm. The original electrode material is placed on one side of the opening in the battery case, an...

Embodiment 2

[0051] (S1), mix 10mg of acetylene black with 80mg of 2wt% polytetrafluoroethylene solution, the solvent of the polytetrafluoroethylene solution is tetrahydrofuran, continue to add tetrahydrofuran until the dispersion is 1mL, and carry out ultrasonic dispersion until uniform and uniform coated on the substrate, and vacuum dried at 130°C for 10 hours to obtain the original electrode material;

[0052] (S2), assemble the metal ion battery in an argon-filled glove box, using a CR2032 button battery case with holes on one side, the hole diameter is 2mm, and the hole density is 5 to 8 holes / cm 2 , the positive electrode is a lithium sheet, and the negative electrode is the original electrode material prepared in (S1) step; the solute of the electrolyte solution is a tetraethylene glycol dimethyl ether solution of 1M lithium trifluoromethanesulfonate, and the diaphragm is a polyethylene diaphragm. The above-mentioned original electrode material is placed on one side of the opening i...

Embodiment 3

[0056] (S1), mix 10mg of super P with 140mg of polyvinyl alcohol solution with a concentration of 5wt%, the solvent of the polyvinyl alcohol solution is N-methylpyrrolidone, continue to add N-methylpyrrolidone until the dispersion is 1mL, and perform ultrasonication Disperse until uniform, and evenly coated on the substrate, 160 ℃ vacuum drying for 10h to obtain the original electrode material;

[0057] (S2), assemble the metal ion battery in an argon-filled glove box, using a CR2032 button battery case with holes on one side, the hole diameter is 2mm, and the hole density is 5 to 8 holes / cm 2 , the positive electrode is a lithium sheet, and the negative electrode is the original electrode material prepared in (S1) step; the solute of the electrolyte solution is ethylene glycol dimethyl ether solution of 1M lithium hexafluorophosphate lithium, and the diaphragm is a ceramic fiber diaphragm, and the original electrode material is placed in On one side of the opening in the batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Hole density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com