Titanium dioxide loaded nickel ferrite and graphene oxide composite thin film, preparation method thereof, and application of titanium dioxide loaded nickel ferrite and graphene oxide composite thin film to wastewater treatment

A technology of titanium dioxide and composite thin films, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, light water/sewage treatment, etc., can solve problems such as low treatment efficiency, secondary pollution, and high energy consumption , to achieve the effects of improving catalytic efficiency, improving utilization efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Mix deionized water, concentrated hydrochloric acid (36.8% by volume), and tetra-n-butyl titanate at a volume ratio of 10:10:0.4, stir and mix well with a magnetic stirrer until the solution is completely clear, and obtain Reaction precursor;

[0032] (2) The fluorine-doped tin dioxide conductive glass was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 15 minutes in sequence, and then soaked in absolute ethanol for use after taking it out;

[0033] (3) Dry the fluorine-doped tin dioxide conductive glass and put it into the polytetrafluoroethylene liner, pour the reaction precursor solution, the conductive surface of the fluorine-doped tin dioxide is facing down, so that the fluorine-doped tin dioxide is completely Soak in the reaction precursor solution, put the liner into the autoclave;

[0034] (4) Put the high-pressure reaction kettle into a 150°C electric heating constant temperature drying oven, and after 5 hours of reaction, tak...

Embodiment 2

[0041] (1) Mix deionized water, concentrated hydrochloric acid (36.8% by volume), and tetra-n-butyl titanate at a volume ratio of 10:10:1, stir and mix well with a magnetic stirrer until the solution is completely clear, and obtain Reaction precursor;

[0042] (2) The fluorine-doped tin dioxide conductive glass was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 15 minutes in sequence, and then soaked in absolute ethanol for use after taking it out;

[0043] (3) Dry the fluorine-doped tin dioxide conductive glass and put it into the polytetrafluoroethylene liner, pour the reaction precursor solution, the conductive surface of the fluorine-doped tin dioxide is facing down, so that the fluorine-doped tin dioxide is completely Soak in the reaction precursor solution, put the liner into the autoclave;

[0044] (4) Put the high-pressure reaction kettle into a 120°C electric heating constant temperature drying oven, and after 8 hours of reaction, take ...

Embodiment 3

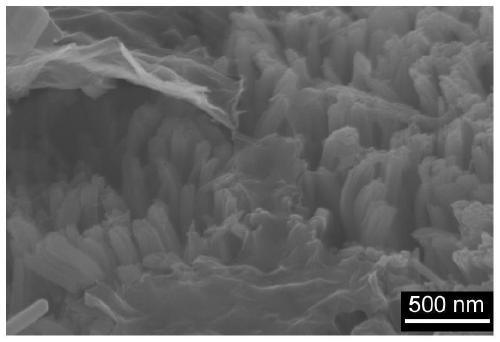

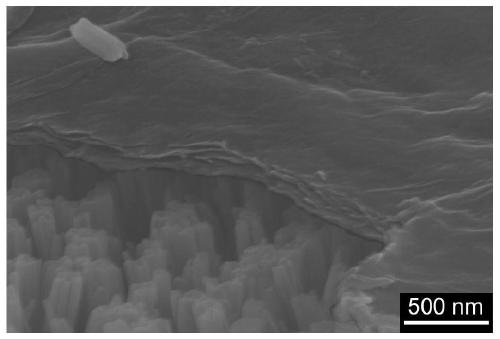

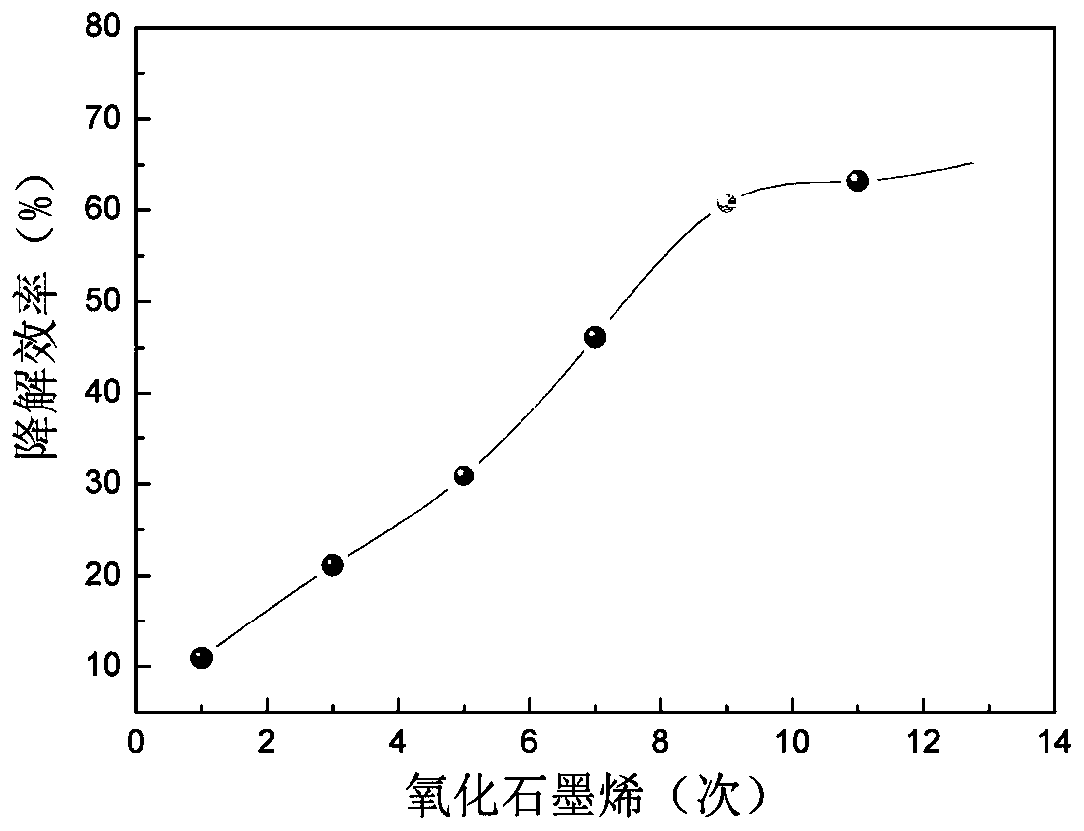

[0050] Example 3: Titanium dioxide-supported nickel ferrite and graphene oxide composite films obtained by different graphene oxide impregnation times.

[0051] Such as image 3 As shown, the composite films of titania-supported nickel ferrite and graphene oxide obtained by different immersion times of graphene oxide were investigated in 90min, and the light intensity was 100mW / cm 2 Under visible light, the degradation rate of 20mg / L unsymmetrical dimethylhydrazine simulated wastewater. As the number of graphene oxide layers increases, the degradation rate of unsymmetrical dimethylhydrazine wastewater also increases, and tends to be saturated after 9 times, because too much graphene oxide will lead to visible light reaching the nickel ferrite. decrease very much.

[0052] After 9 depositions of graphene oxide, the catalytic degradation efficiency of titanium dioxide-supported nickel ferrite and graphene oxide composite film is compared with that of titanium dioxide-supported...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com