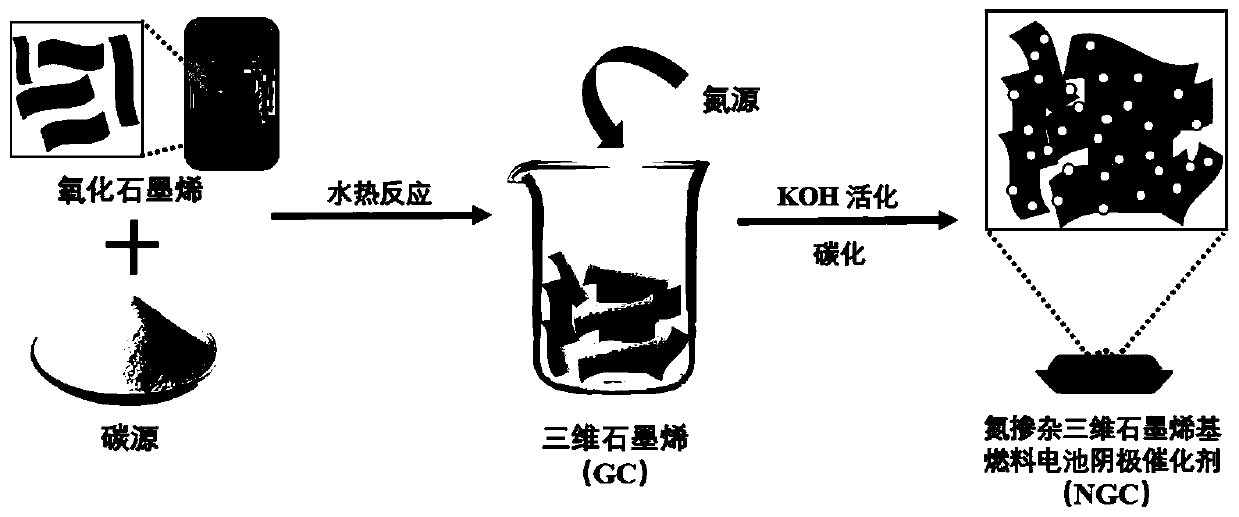

Preparation method of nitrogen-doped three-dimensional graphene-based fuel cell cathode catalyst

A fuel cell cathode, graphene-based technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of hindering graphene catalytic sites, easy aggregation and stacking of materials, lack of mass transfer channels, etc., to speed up electron transfer, High mobility and effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] Step 1. Uniformly disperse 20mg of graphene oxide, 800mg of glucose and 10mg of sodium lauryl sulfate in 10mL of deionized water to obtain a dispersion, and then place the dispersion in a high-pressure chamber with a volume of 25mL and lined with polytetrafluoroethylene Under the condition of 180°C in the reaction kettle, hydrothermally react for 12 hours, then centrifuge and wash for 15 minutes at a speed of 8500rmp, and then freeze-dry to obtain a three-dimensional graphene material;

[0035] Step 2. Mix 50 mg of the three-dimensional graphene material obtained in step 1 with 500 mg of melamine and 500 mg of potassium hydroxide, and then place it in a tube furnace for high-temperature carbonization under the protection of argon, and wash it with 1M hydrochloric acid after cooling to 25°C until the filtrate is neutral, and then dried to obtain a nitrogen-doped three-dimensional gra...

Embodiment 2

[0044] The preparation method of the present embodiment comprises the following steps:

[0045] Step 1. Uniformly disperse 25mg of graphene oxide, 800mg of glucose and 10mg of sodium lauryl sulfate in 10mL of deionized water to obtain a dispersion, and then place the dispersion in a high-pressure chamber with a volume of 25mL and lined with polytetrafluoroethylene Under the condition of 170°C in the reaction kettle, hydrothermally react for 14 hours, then centrifuge and wash for 20 minutes at a speed of 8000rmp, and then freeze-dry to obtain a three-dimensional graphene material;

[0046] Step 2: Mix 60 mg of the three-dimensional graphene material obtained in Step 1 with 500 mg of urea and 500 mg of potassium hydroxide, and then place it in a tube furnace for high-temperature carbonization under the protection of argon, and wash it with 1M hydrochloric acid after cooling to 25°C until the filtrate is neutral, and then dried to obtain a nitrogen-doped three-dimensional graphen...

Embodiment 3

[0048] The preparation method of the present embodiment comprises the following steps:

[0049] Step 1. Uniformly disperse 30mg of graphene oxide, 800mg of glucose and 10mg of sodium lauryl sulfate in 10mL of deionized water to obtain a dispersion, and then place the dispersion in a high-pressure chamber with a volume of 25mL and lined with polytetrafluoroethylene Under the condition of 160°C in the reaction kettle, hydrothermally react for 16 hours, then centrifuge and wash at 7500rmp for 25 minutes, and then freeze-dry to obtain a three-dimensional graphene material;

[0050] Step 2. Mix 65 mg of the three-dimensional graphene material obtained in step 1 with 500 mg of melamine and 500 mg of potassium hydroxide, and then place it in a tube furnace for high-temperature carbonization under the protection of argon. After cooling to 25 ° C, wash with 1M hydrochloric acid until the filtrate is neutral, and then dried to obtain a nitrogen-doped three-dimensional graphene-based fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com