Application of three-dimensional carbon doped tricobalt tetraoxide material

A three-dimensional technology of cobalt tetroxide, applied in the field of application of cobalt tetroxide materials, can solve the problems of poor catalytic activity and stability of electrocatalysts, and achieve the effects of ingenious experimental design, reducing overall resistance and enhancing conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add borax and glucose to deionized water at a mass ratio of 1:26, wherein the mass ratio of borax to deionized water is 1:30, and place the solution in an oven at 180°C for 8 hours to prepare carbon gel; The carbon gel was washed successively with water and ethanol respectively, and dried in an oven at 80°C to obtain a carbon aerogel;

[0034] (2) Add the carbon aerogel and cobalt acetate in step (1) to ethylene glycol respectively, and react for 14 hours by solvothermal reaction, specifically: react at 120°C for 12h, then react at 170°C for 2h; The mass ratio of gelatin, cobalt acetate, and ethylene glycol is 1:1:120, and the obtained solution is filtered and washed, and vacuum-dried at 80°C to obtain carbon aerogels adsorbed with transition metals;

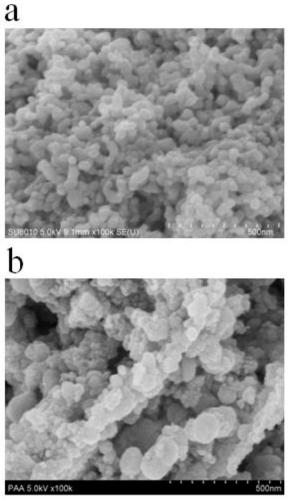

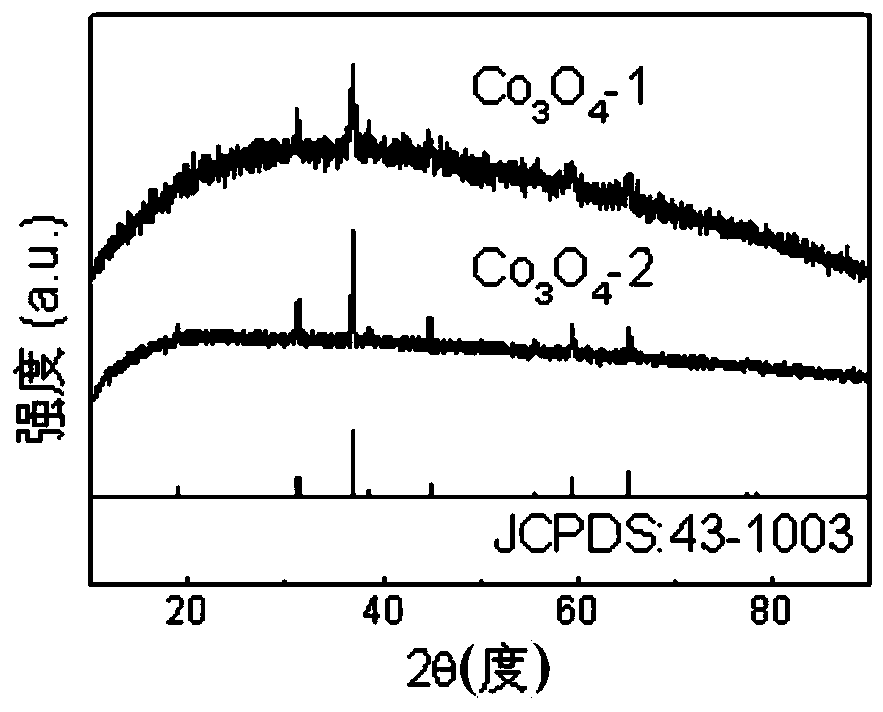

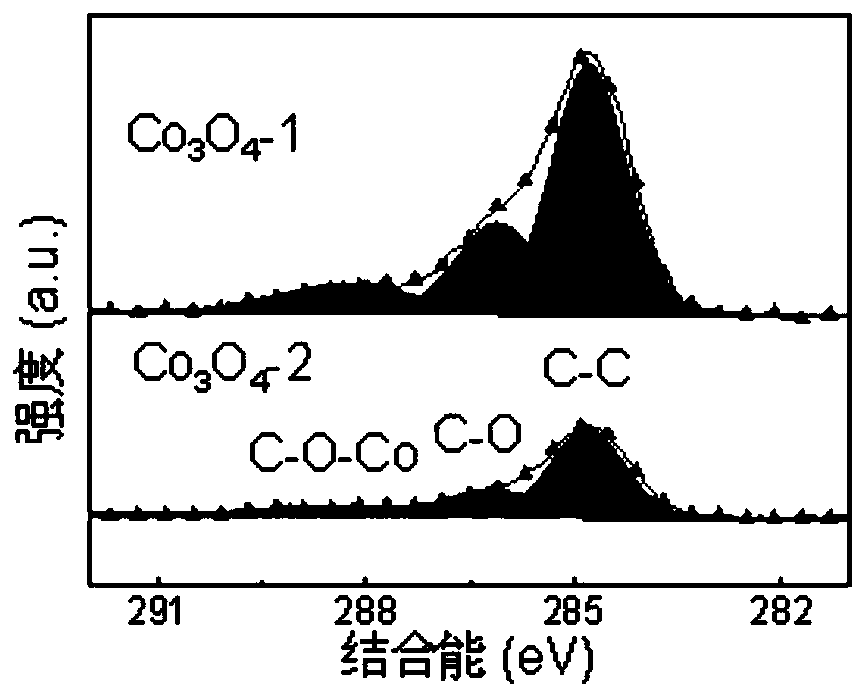

[0035] (3) The transition metal-adsorbed carbon airgel obtained in step (2) was subjected to a high-temperature treatment at 500°C for 4 hours in the air to obtain a three-dimensional carbon-doped tricobalt tetroxide ...

Embodiment 2

[0037] OER and HER test:

[0038] (1) 7mg of Co 3 o 4 -1 sample and 3.5 mg of acetylene black were dispersed into 350 μL of ethanol and 95 μL of Nafion mixed solution (5 wt %) to prepare a catalyst ink.

[0039] (2) 7 μL of catalyst ink was deposited on a 5 mm diameter glassy carbon electrode with a mass loading of ~0.39 mg cm -2 , and dried at room temperature.

[0040] (3) Linear sweep voltammetry (LSV) was performed using a CHI 660D electrochemical workstation, using a standard three-electrode system with an Ag / AgCl electrode as a reference electrode, a graphite rod as a counter electrode, and a catalyst-coated rotating disk The electrode is used as the working electrode, the electrolyte is 1M KOH solution, and the scan rate is 5mV s -1 .

Embodiment 3

[0042] Full water decomposition performance test:

[0043](1) Ultrasonicize the above catalyst ink for 30 minutes, drop-coat it on two pieces of 1cm*1cm carbon paper, the area load is about 0.4mg cm -2 , and dried at room temperature.

[0044] (2) Two pieces of carbon paper were used as cathode and anode respectively, and 1M KOH was used as electrolyte, at 10mA cm -2 The cycle performance test was carried out under the current density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com