Medical titanium alloy surface coating and preparation method thereof

A surface coating and titanium alloy technology, applied in the direction of surface reaction electrolytic coating, metal material coating process, coating, etc., can solve the problems of insufficient antibacterial infection ability, peeling off of the coating on the surface of titanium alloy, and induced inflammation. Achieve the effects of improving anti-bacterial infection ability, solving poor biological activity, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

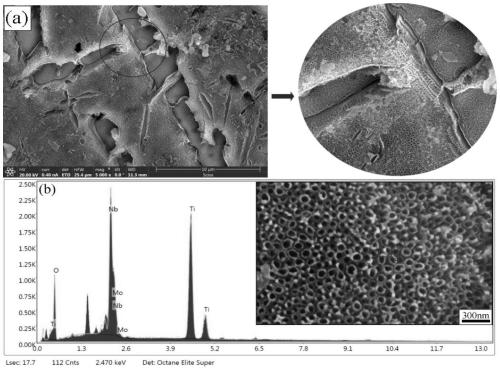

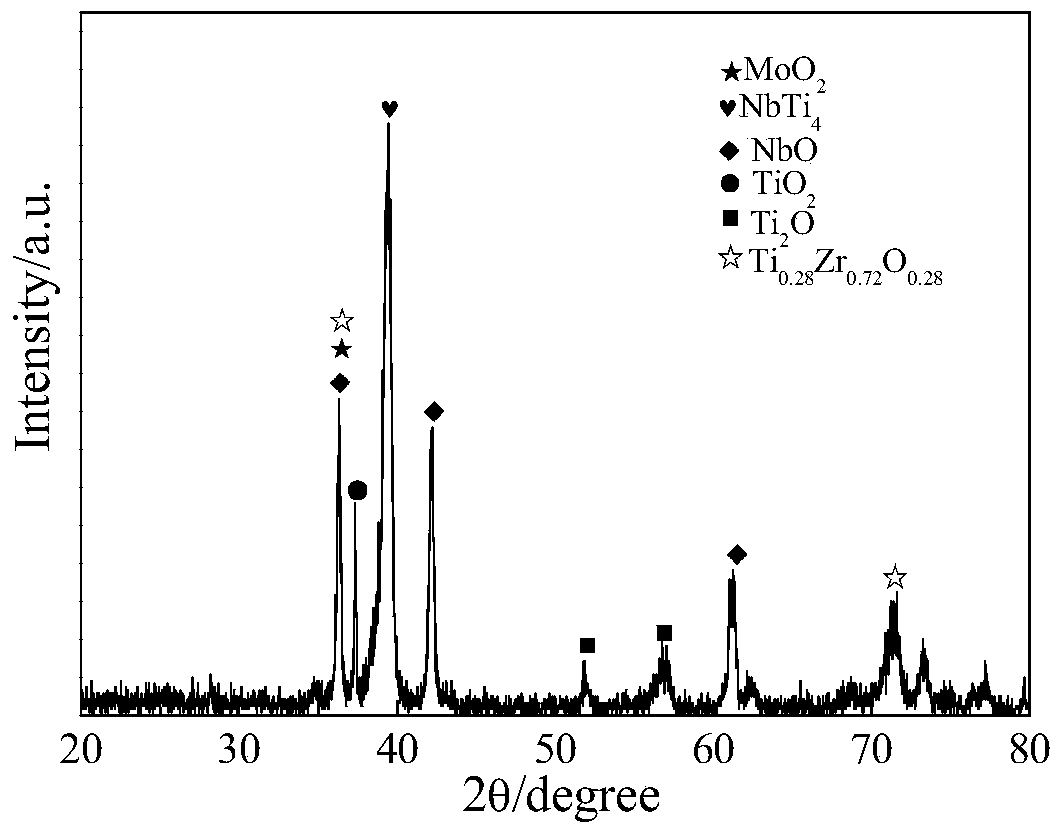

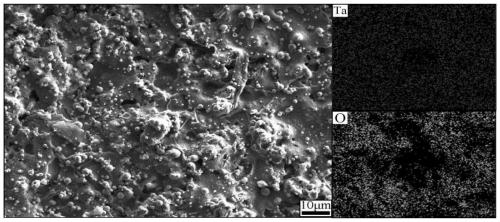

[0029] A medical titanium alloy surface coating: the titanium alloy surface coating is a Ta or Ta-Cu-Zn composite coating on the surface of a Ti-27Nb-6Zr-5Mo alloy. The composition ratio of the Ta-Cu-Zn composite coating is: Ta:Cu:Zn=98 wt%:1 wt%:1 wt%.

[0030] Preparation method of Ti-27Nb-6Zr-5Mo alloy: Mo element is added on the basis of the basic ratio of Ti-27Nb-6Zr alloy, and the range of Mo addition is 5 wt%. The basic ratio of Ti-27Nb-6Zr is based on the cluster model structural formula [TiTi 13.4 Zr 0.6 ]Nb 3 Based on the addition of Mo element, Mo replaces the central atom Ti, and the cluster model formula is [Ti 1- y Mo y Ti 13.4 Zr 0.6 ]Nb 3 , thus designing the basic ratio Ti-27Nb-6Zr. The ingredients calculation is shown in Table 0.

[0031] Table 0 Calculation of ingredients of Ti-27Nb-Zr-Mo alloy

[0032]

[0033] (1) Calculate the mass percentage of each element in the alloy, in TiH 2 , Nb powder, Zr powder and Mo powder as raw materials, accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com