Formaldehyde removal decorative plate and preparation method thereof

A decorative board and formaldehyde technology, applied in the field of formaldehyde removal decorative board and its preparation, can solve the problems of not reaching the desired effect, small adsorption surface, easy to be released twice, etc. Effects of adsorption capacity and adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

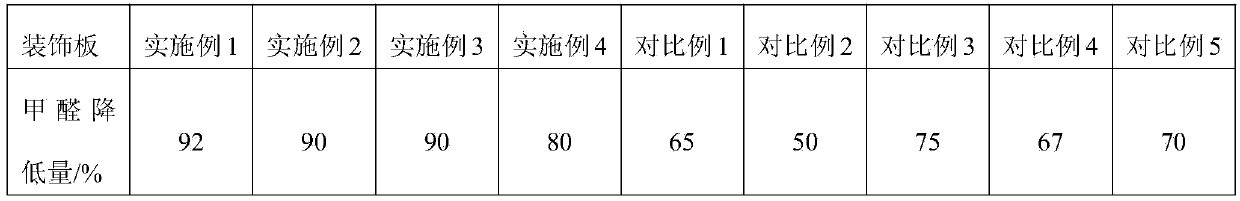

Examples

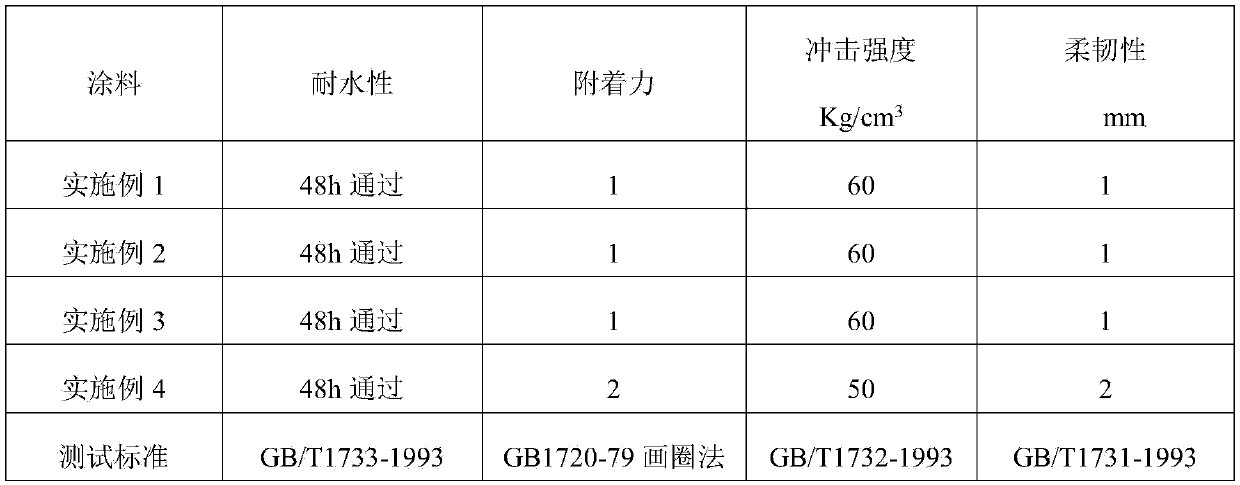

Embodiment 1

[0046] A formaldehyde-removing decorative board includes a base material and a decorative layer, an adsorption layer is included between the base material and the decorative layer, and a functional paint layer is also placed on the surface of the decorative layer.

[0047] The adsorption layer includes the following components in parts by weight: 20 parts of diatomite, 10 parts of activated carbon, 8 parts of biochar and 15 parts of volcanic stone particles.

[0048] The functional coating layer comprises the following components in parts by weight: activated carbon supported nano-TiO 2 8 parts of materials, 4 parts of chitosan, 4 parts of rosin resin, 0.5 parts of nano-graphene, 8 parts of lignin, 3 parts of plant extract, 2 parts of light calcium, 1 part of biological enzyme, 40 parts of silicon-acrylic emulsion, film-forming 0.2 parts of additives, 0.5 parts of defoamer, 0.5 parts of dispersant and 30 parts of water.

[0049] The biological enzymes include peroxidase, form...

Embodiment 2

[0072] A formaldehyde-removing decorative board includes a base material and a decorative layer, an adsorption layer is included between the base material and the decorative layer, and a functional paint layer is also placed on the surface of the decorative layer.

[0073] The adsorption layer comprises the following components in parts by weight: 30 parts of diatomite, 5 parts of activated carbon, 10 parts of biochar and 20 parts of volcanic stone particles.

[0074] The functional coating layer comprises the following components in parts by weight: activated carbon supported nano-TiO 2 10 parts of materials, 3 parts of chitosan, 5 parts of rosin resin, 0.1 parts of nano-graphene, 10 parts of lignin, 1 part of plant extract, 5 parts of light calcium, 2 parts of biological enzyme, 30 parts of silicon-acrylic emulsion, film-forming 1 part of auxiliary agent, 0.05 part of defoamer, 1 part of dispersant and 20 parts of water.

[0075] The biological enzymes include peroxidase, f...

Embodiment 3

[0086] A formaldehyde-removing decorative board includes a base material and a decorative layer, an adsorption layer is included between the base material and the decorative layer, and a functional paint layer is also placed on the surface of the decorative layer.

[0087] The adsorption layer comprises the following components in parts by weight: 15 parts of diatomite, 20 parts of activated carbon, 10 parts of biochar and 10 parts of volcanic stone particles.

[0088] The functional coating layer comprises the following components in parts by weight: activated carbon supported nano-TiO 25 parts of materials, 5 parts of chitosan, 5 parts of rosin resin, 1 part of nano-graphene, 10 parts of lignin, 5 parts of plant extract, 1 part of light calcium, 0.5 parts of biological enzyme, 30 parts of silicon-acrylic emulsion, film-forming 0.05 part of auxiliary agent, 0.05 part of defoamer, 0.05 part of dispersant and 20 parts of water.

[0089] The biological enzymes include peroxidas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com