LLZO preparation method, thermal cell quasi-solid electrolyte, and preparation method thereof

An electrolyte, quasi-solid-state technology, applied in the field of material chemistry, can solve the problems of short calcination time, high corrosion of equipment, no large-scale production, etc., and achieve good thermal stability, high ion mobility, and small grain boundary resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of quasi-solid electrolyte for thermal battery of the present invention comprises:

[0029] Step 1, in an environment with a dew point lower than -40°C, the La 2 o 3 Baking at 800℃~1000℃ for 12h~15h to remove La(OH) 3 Impurities, the Li 2 CO 3 , ZrO 2 、H 2 C 2 o 4 Place the eutectic salt with alkali metal halides in a blast drying oven, dry for 2 hours to 4 hours, and the drying temperature is 120 ° C to 150 ° C;

[0030] Preferably, the alkali metal halide eutectic salt is a LiF-LiCl-LiBr system (the mass percentage of LiF in the system is 8-11%, the mass percentage of LiCl is 21-23%, and the mass percentage of LiBr 67-70%), LiCl-LiBr-KBr system (the mass percentage of LiCl in the system is 11-13%, the mass percentage of LiBr is 35-38%, and the mass percentage of KBr is 50-53%) or LiCl-KCl system (the mass percentage of LiCl in the system is 44-46%, the mass percentage of KCl is 54-56%);

[0031] Step 2, according to the component conte...

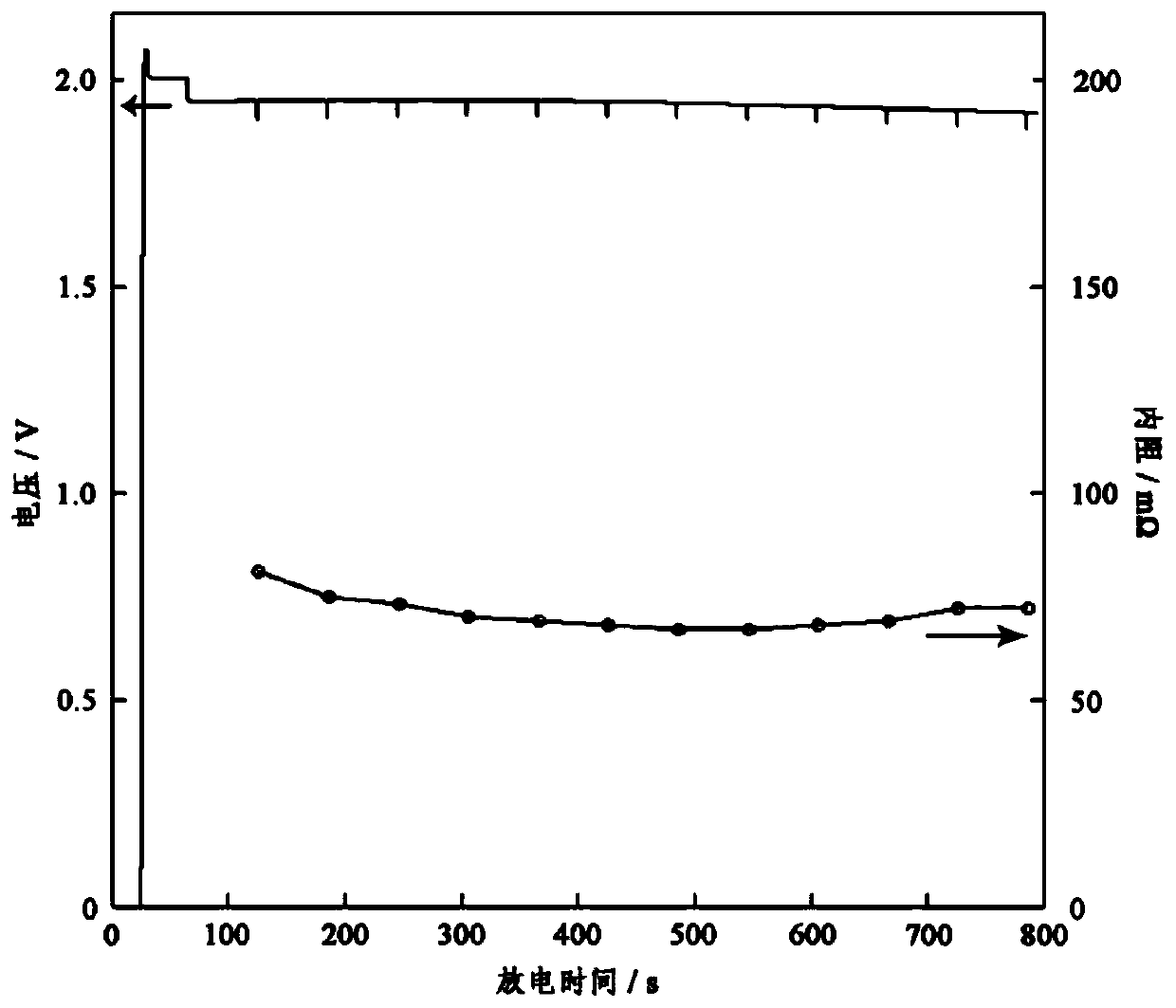

Embodiment 1

[0037] The amount of each raw material is calculated according to the ratio of each component in the target product quasi-solid electrolyte. In this example, in an environment with a dew point lower than -40°C, the La 2 o 3 Placed at 900°C for 12 hours to remove La(OH) 3 Impurities, weigh 98g of La after heat treatment 2 o 3 , 57g Li 2 CO 3 (10% excess), 49g ZrO 2 , 306 g H 2 C 2 o 4 (accounting for La 2 o 3 , Li 2 CO 3 , ZrO 2 and H 2 C 2 o 4 60% of the total mass of the four materials) and 30g LiF-LiCl-LiBr system eutectic salt (accounting for 15% of the quasi-solid electrolyte quality), the Li 2 CO 3 , ZrO 2 、H 2 C 2 o 4 The eutectic salt of LiF-LiCl-LiBr system was placed in a blast drying oven, and dried for 2 hours at a drying temperature of 120°C. 98g La 2 o 3 , 57g Li 2 CO 3 , 49 g ZrO 2 and 306g H 2 C 2 o 4 Put it into an agate mortar, grind it evenly, put it into a stainless steel tank, bake it at 1200°C for 2 hours, cool it down to roo...

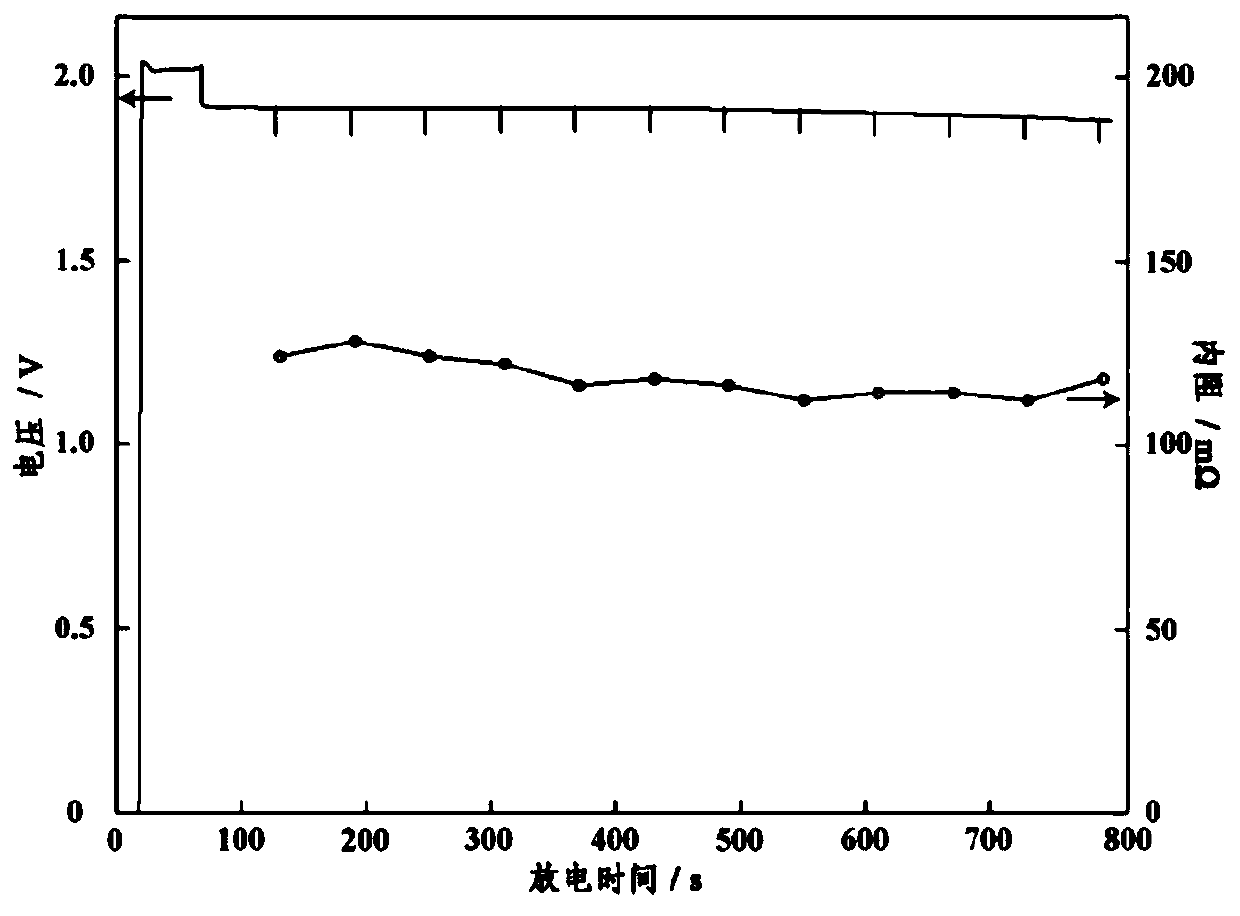

Embodiment 2

[0041] The amount of each raw material is calculated according to the ratio of each component in the target product quasi-solid electrolyte. In this example, in an environment with a dew point lower than -40°C, the La 2 o 3 Placed at 900°C for 12 hours to remove La(OH) 3 Impurities, weigh 98g of La after heat treatment 2 o 3 , 57g Li 2 CO 3 (10% excess), 49g ZrO 2 , 408 g H 2 C 2 o 4 (accounting for La 2 o 3 , Li 2 CO 3 , ZrO 2 and H 2 C 2 o 4 67% of the total mass of the four materials) and 9g LiCl-KCl system eutectic salt (accounting for 5% of the quasi-solid electrolyte quality), the Li 2 CO 3 , ZrO 2 、H 2 C 2 o 4 Place the eutectic salt with LiCl-KCl system in a forced air drying oven and dry for 2 hours at a drying temperature of 120°C. 98g La 2 o 3 , 57g Li 2 CO 3 , 49 g ZrO 2 and 408g H 2 C 2 o 4 Put it into an agate mortar, grind it evenly, put it into a stainless steel tank, bake it at 1200°C for 2 hours, cool it down to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal resistance | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com