Method for producing 1,5-pentanediamine through immobilized lysine decarboxylase

A technology of lysine decarboxylase and immobilized enzyme, which is applied in the field of immobilized lysine decarboxylase to produce pentamethylenediamine, can solve the problems of chemical pollutant discharge, unfavorable industrialization process, large reaction discharge pollution, etc., and achieve The effect of high productivity, simplified separation process of downstream products, and small loss of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

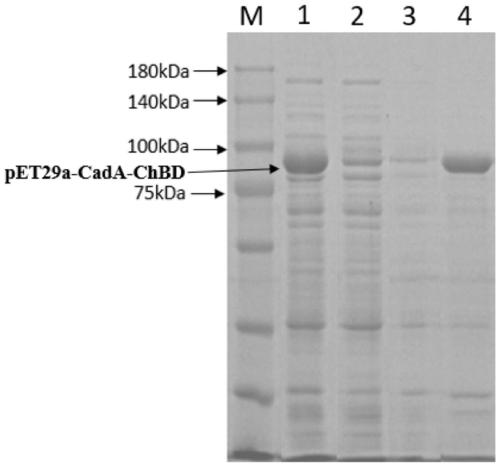

[0046] Construction of embodiment 1 fusion protein particles

[0047] Bacterial Genome Extraction Kit (TianGen) was used to extract Escherichia coli MG1655 (purchased from Wuhan Miaoling Biotechnology Co., Ltd.) and from Jiangnan University Jiangnan University Hao Zhikui donated Chitinolytic bacteria meiyuanensis SYBC-H1 (ATCC BAA-2140 T ), the lysine decarboxylase gene CadA and the chitin-binding domain gene ChBD were amplified by PCR respectively.

[0048] Use the following primers

[0049] 1: 5'-CGGGATCCTTCTTTCAATACCTTAACGG-3'

[0050] 2: 5'-CATGCCATGGATGAACGTTATTGCAATATTG-3'

[0051] by E. coli The total DNA of MG1655 was used as a template for PCR amplification. After the PCR reaction, the target fragment with a size of 2.1 kb was obtained by digestion at the Ncol I and Bam HI restriction sites CadA After nucleic acid gel verification, the target gene was recovered by gel recovery kit (TianGen).

[0052] Use the following primers

[0053] 3: 5'-CCCAAGCTTCGGCG...

Embodiment 2

[0059] Example 2 Preparation of lysine decarboxylase crude enzyme solution

[0060] Prepare the seed solution of the constructed lysine decarboxylase-producing bacteria, the medium is LB medium, culture at 37°C and 200rpm for 6-7h, inoculate the seed solution with a volume fraction of 2% in the fermentation medium containing 500ml LB , cultivated at 37°C and 200rpm until the OD was 0.6, added the inducer IPTG at an amount of 1‰, induced at 30°C and 200rpm for 12h, and then finished the fermentation to collect the fermentation broth.

[0061] After centrifuging the fermentation broth at 8000g, collect the bacteria, wash twice with distilled water, resuspend in 25ml of citric acid-disodium hydrogen phosphate (100mM pH6.8), ultrasonically crush and centrifuge at 8000g, and collect the supernatant as Lai Amino acid decarboxylase crude enzyme solution, stored at 4°C for later use.

Embodiment 3

[0062] Example 3 Affinity adsorption of lysine decarboxylase and chitin

[0063] Take 10 ml of the crude lysine decarboxylase enzyme solution obtained in Example 2, add 0.1 g of high-pressure homogenized chitin powder to perform affinity adsorption of lysine decarboxylase. After the adsorption is completed, centrifuge at 6000g to remove the supernatant and collect the precipitate, which is the chitin powder (immobilized enzyme) with lysine decarboxylase adsorbed as we need. After washing twice with distilled water, the washed immobilized lysine decarboxylase was collected and stored at 4°C for future use. The adsorption environment parameters were temperature 20°C, stirring speed 200rpm, and pH 6.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com