A kind of surface treatment method of buoyant material

A buoyant material and surface treatment technology, used in epoxy resin coatings, coatings, etc., can solve the problems of damaged waterproof layer, high brittleness of waterproof layer, easy to be exposed to direct sunlight, etc., to ensure stability, reduce water absorption, guarantee The effect of the defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A surface treatment method for a buoyant material, comprising the steps of:

[0036] 1) Fix the buoyancy material to be processed in the container, and place it directly below the pouring port in the vacuum pouring tank, and then vacuumize, and the vacuum pressure is lower than 1000Pa;

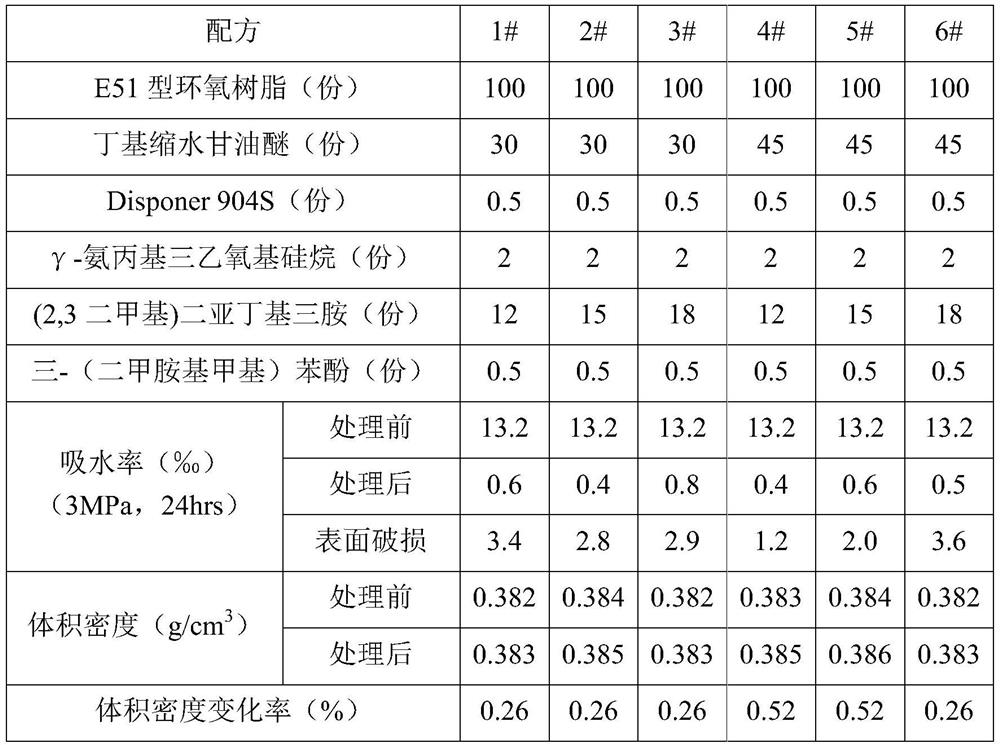

[0037] 2) In parts by mass, pour 100 parts of E51 type epoxy resin, 30 parts of butyl glycidyl ether, 2 parts of γ-aminopropyltriethoxysilane, and 0.5 parts of Disponer 904S into the mixing tank of the vacuum casting tank , stirred at room temperature for 10 minutes, and then defoamed for 15 minutes under vacuum, the vacuum pressure was lower than 1000Pa; base) phenol, stirred at room temperature for 5 minutes;

[0038] 3) Open the valve of the feeding port of the mixing tank, let the resin mixture flow into the container with the buoyancy material until the liquid level is 2-3cm higher than the upper surface of the buoyancy material; open the air inlet of the vacuum casting tank, and us...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is that in step 2), the resin mixture is: 100 parts of E51 type epoxy resin, 30 parts of butyl glycidyl ether, 2 parts of γ-aminopropyl triethoxysilane, 0.5 parts of Disponer 904S, 15 parts of (2,3 dimethyl)dibutylenetriamine and 0.5 parts of tris-(dimethylaminomethyl)phenol.

Embodiment 3

[0043] The difference between embodiment 3 and embodiment 1 is that in step 2), the resin mixture is: 100 parts of E51 type epoxy resin, 30 parts of butyl glycidyl ether, 2 parts of γ-aminopropyl triethoxysilane, 0.5 parts of Disponer 904S, 18 parts of (2,3 dimethyl)dibutylenetriamine and 0.5 parts of tris-(dimethylaminomethyl)phenol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com